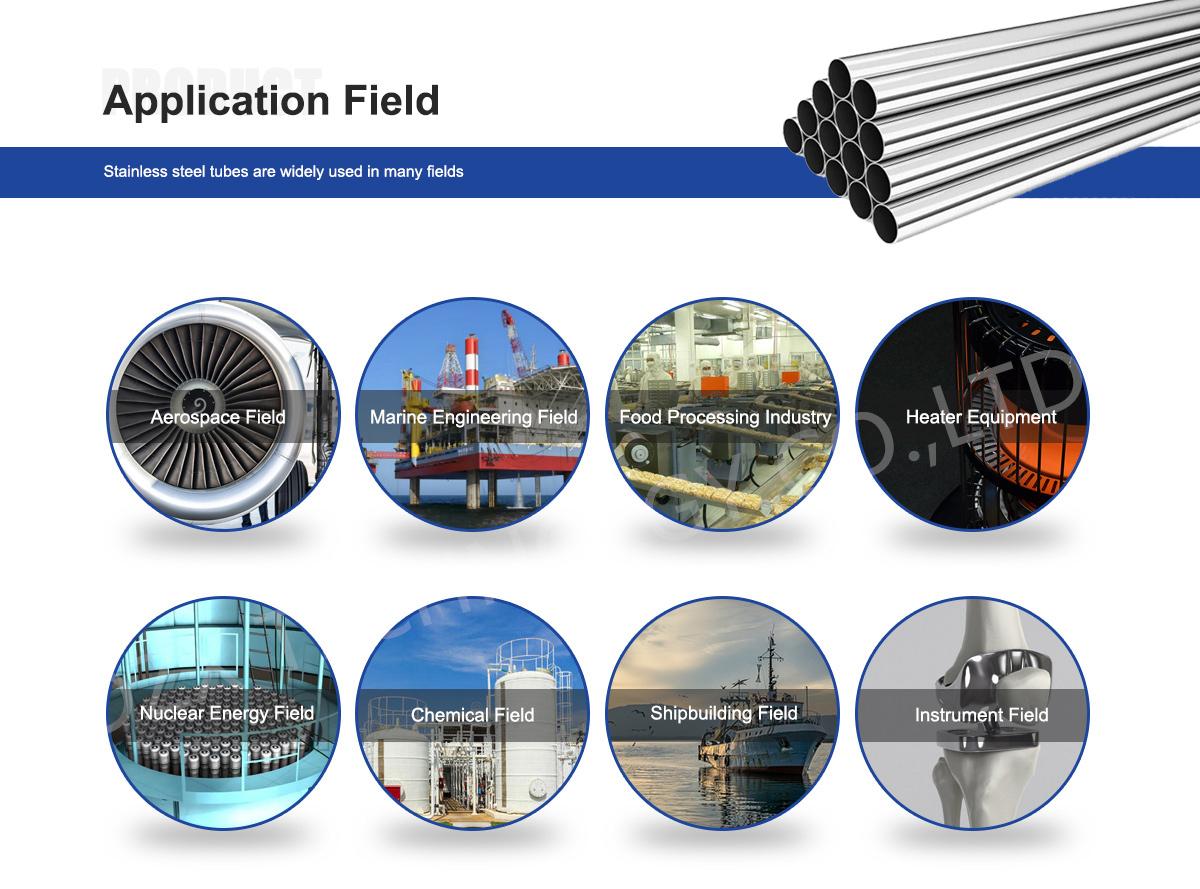

We're all about delivering top-notch 304 stainless steel tube for orthopedic device manufacturing right here at our company. You know, when it comes to crafting reliable, high-performance components that surgeons and patients can count on, our 304 stainless steel tube stands out as a go-to choice. Let's dive into what makes this product so essential, starting with a solid introduction to what it is and why it's perfect for the job.

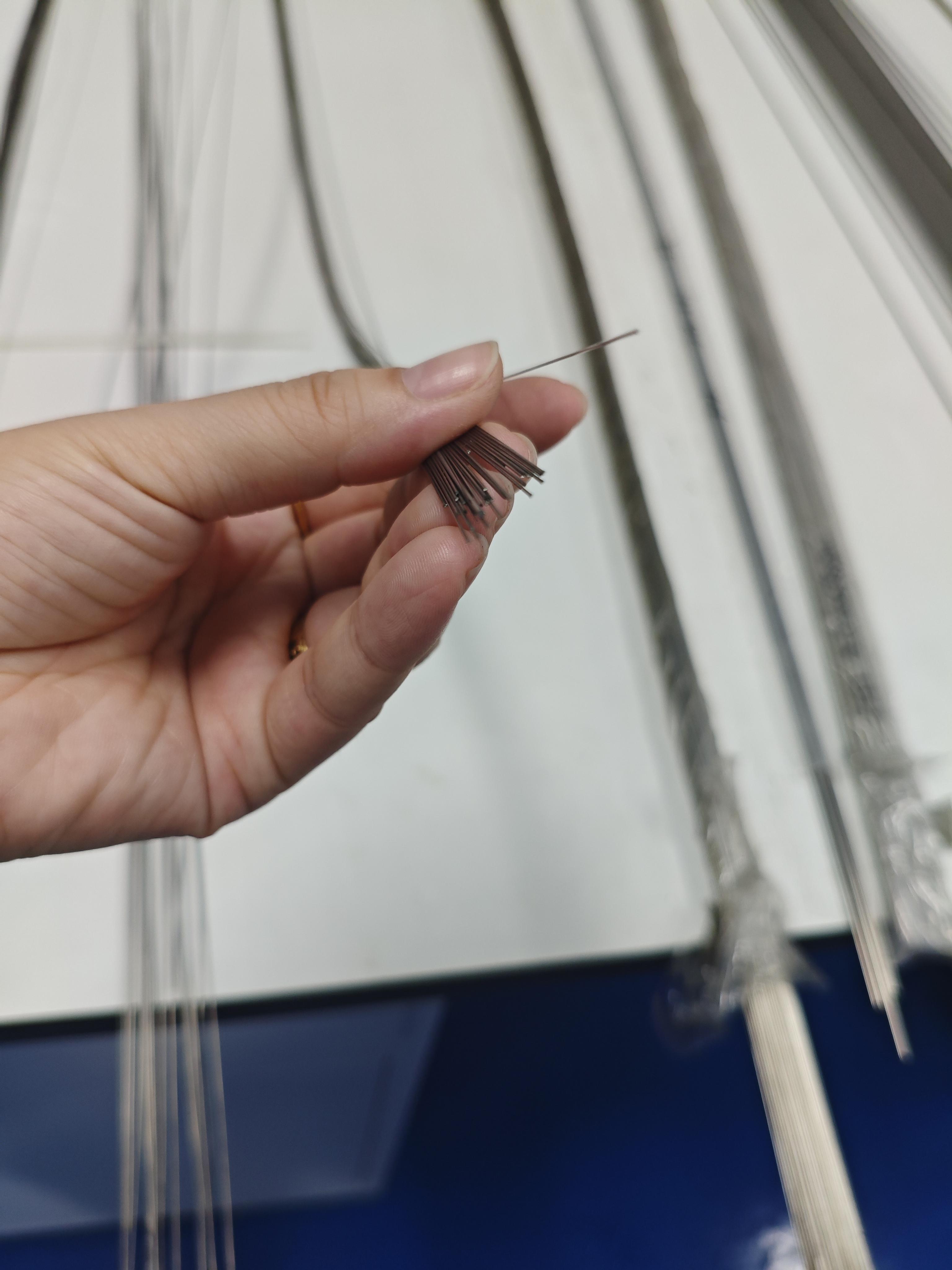

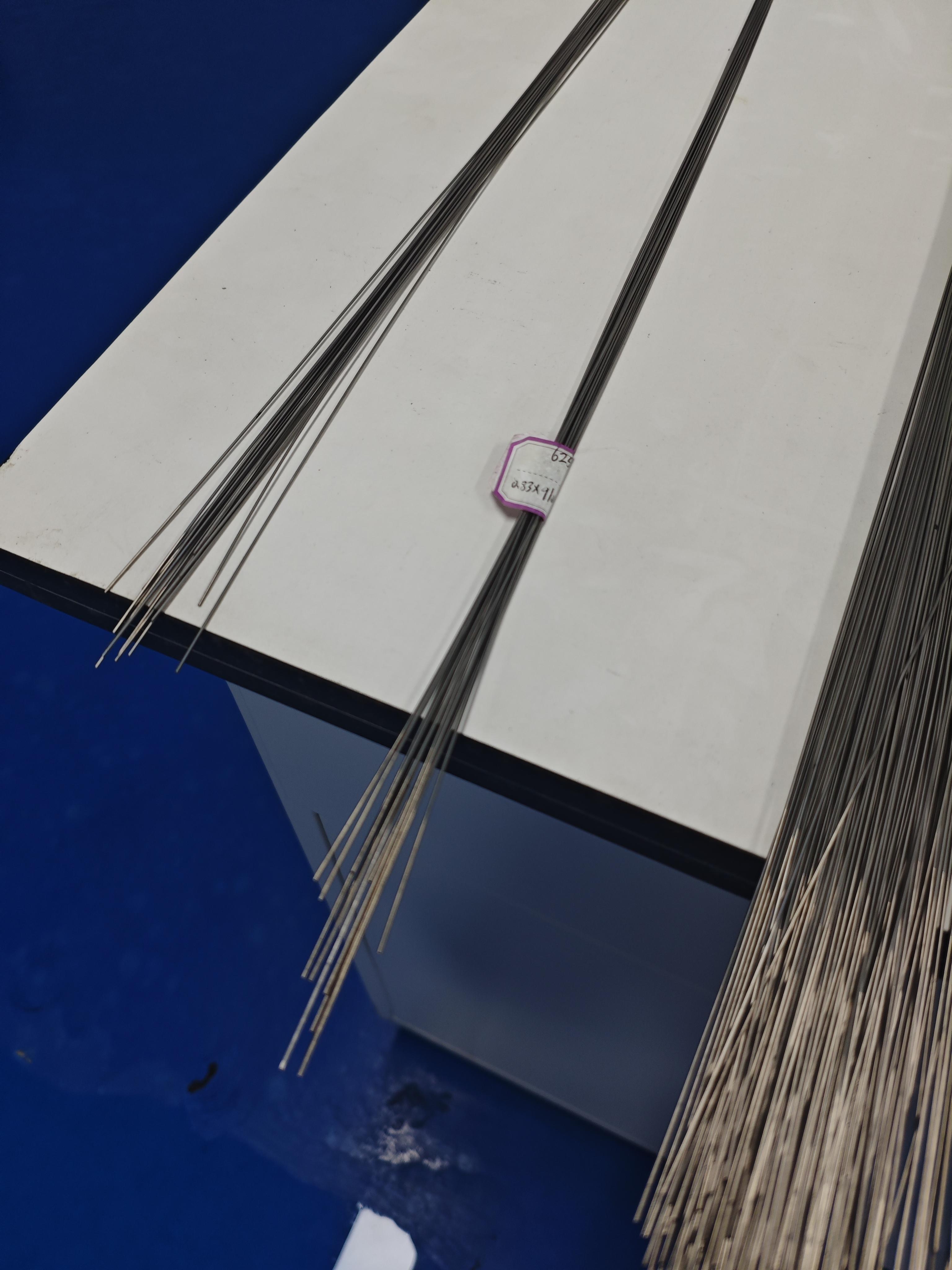

Our 304 stainless steel tube is an austenitic alloy that's been fine-tuned for medical applications, especially in orthopedic device manufacturing. It's made up of about 18% chromium and 8% nickel, with just a tiny bit of carbon—around 0.08%—and the rest iron, plus some manganese and silicon to boost its strength and formability. What this means is you get a tube that's incredibly resistant to corrosion, non-magnetic, and super biocompatible, which is crucial when it's going inside the human body or being used in surgical settings. We produce these tubes in various diameters, wall thicknesses, and lengths, all customized to meet the precise needs of orthopedic implants, surgical instruments, and support devices. Whether it's seamless or welded, our manufacturing process ensures smooth surfaces, tight tolerances, and that medical-grade polish that prevents any bacterial buildup. In orthopedic device manufacturing, where precision can make the difference between a successful surgery and complications, our 304 stainless steel tube delivers the durability and reliability you expect.

For more details, pls directly contact us.

Now, shifting gears to the bigger picture—the industry analysis. The orthopedic device manufacturing sector is booming, and we're right in the thick of it. By 2025, the global orthopedic devices market is projected to hit around $68 billion, growing at a steady 4.8% CAGR. What's driving this? An aging population that's more active than ever, leading to higher rates of joint replacements, spinal fusions, and fracture repairs. Then there's the rise in sports injuries and chronic conditions like osteoporosis, all fueling demand for advanced orthopedic solutions. But it's not just about volume; trends are leaning toward minimally invasive procedures, where smaller, more precise components like our 304 stainless steel tube play a key role in tools for arthroscopy or robotic-assisted surgeries. Sustainability is another big push—manufacturers are focusing on recyclable materials and eco-friendly processes, and our 304 stainless steel tube fits right in, being fully recyclable without losing its properties. Regulatory scrutiny is tightening too, with bodies like the FDA emphasizing biocompatibility and traceability, which is why we invest heavily in certifications and quality controls. On top of that, emerging markets in Asia and Latin America are expanding access to orthopedic care, creating new opportunities for high-quality materials. We're seeing a shift toward personalized medicine, with 3D printing and AI integration allowing for custom implants made from durable alloys like 304 stainless steel. Overall, the industry is evolving toward smarter, more efficient manufacturing, and our expertise in 304 stainless steel tube for orthopedic device manufacturing positions us to lead the way.

Comparison of Medical Stainless Steel Grades, Materials, and Applications

Grade | Composition | Key Properties | Corrosion Resistance | Biocompatibility | Applications | Advantages | Limitations |

|---|---|---|---|---|---|---|---|

316L | Fe (60-70%), Cr (16-18%), Ni (10-14%), Mo (2-3%), C (<0.03%) | Tensile: 485-620 MPa, Yield: 170-290 MPa, Elongation: 40-50%, Hardness: 95 HRB | Excellent (passive oxide layer, resists pitting) | High, minimal ion release, rare Ni sensitivity | Bone plates, screws, stents, hip stems, dental implants | Cost-effective, machinable, fatigue-resistant | Possible Ni sensitivity, heavier than Ti |

304L | Fe (65-74%), Cr (18-20%), Ni (8-10.5%), C (<0.03%) | Tensile: 485-550 MPa, Yield: 170-240 MPa, Elongation: 40-55%, Hardness: 92 HRB | Good, less resistant to pitting than 316L | Moderate, higher Ni release risk | Temporary implants, surgical tools, guidewires | Affordable, easy to form, widely available | Limited for long-term implants due to corrosion |

17-4 PH | Fe (70-78%), Cr (15-17.5%), Ni (3-5%), Cu (3-5%), C (<0.07%) | Tensile: 930-1100 MPa, Yield: 725-860 MPa, Hardness: 30-44 HRC | Very good, but less than 316L in saline | Good, but less biocompatible than 316L | Load-bearing implants, surgical instruments | High strength, heat-treatable, durable | Complex processing, less corrosion-resistant |

420 | Fe (80-90%), Cr (12-14%), C (0.15-0.4%) | Tensile: 700-950 MPa, Yield: 340-450 MPa, Hardness: 45-50 HRC | Moderate, prone to pitting in body fluids | Moderate, not ideal for long-term implants | Cutting tools, temporary pins, dental drills | High hardness, wear-resistant, sharpenable | Poor corrosion resistance for permanent use |

440C | Fe (78-85%), Cr (16-18%), C (0.95-1.2%) | Tensile: 760-1000 MPa, Yield: 450-600 MPa, Hardness: 56-60 HRC | Moderate, better than 420 but less than 316L | Limited, high carbon affects biocompatibility | Surgical blades, high-wear tools | Extremely hard, excellent edge retention | Not suitable for long-term implants |

F138 (316LVM) | Fe (60-70%), Cr (17-19%), Ni (13-15%), Mo (2.25-3.5%), C (<0.03%) | Tensile: 490-690 MPa, Yield: 190-300 MPa, Elongation: 40-50%, Hardness: 95 HRB | Superior, optimized for medical use | Excellent, lowest ion release, vacuum-melted | Orthopedic implants, cardiovascular stents | Enhanced purity, top biocompatibility | Higher cost than standard 316L |

303 | Fe (65-75%), Cr (17-19%), Ni (8-10%), S (0.15-0.35%) | Tensile: 500-620 MPa, Yield: 240-290 MPa, Elongation: 35-50%, Hardness: 90 HRB | Moderate, sulfur reduces corrosion resistance | Moderate, not ideal for permanent implants | Machined components, non-implant devices | Excellent machinability, cost-effective | Not suitable for long-term implants |

Nitronic 60 | Fe (60-70%), Cr (16-18%), Ni (8-9%), Mn (7-9%), N (0.08-0.18%) | Tensile: 620-793 MPa, Yield: 345-414 MPa, Hardness: 95-100 HRB | Very good, resists galling and wear | Good, but less studied for implants | Wear-resistant implants, joint components | High wear resistance, galling resistance | Limited medical use, higher cost |

For more details, pls directly contact us

When it comes to applications, our 304 stainless steel tube shines in a variety of orthopedic scenarios. Take bone fixation devices, for instance—these tubes are often used to create pins, screws, and rods that hold fractured bones in place during healing. Their high tensile strength ensures they can bear weight without bending or breaking, which is vital for patient mobility. In surgical instruments, like drills or reamers, the tube's corrosion resistance means it can handle repeated sterilization cycles without degrading, keeping tools sharp and safe. We've also seen it in hypodermic tubing for injections or fluid delivery during orthopedic procedures, where precision diameters prevent blockages and ensure smooth flow. For spinal applications, our 304 stainless steel tube forms the backbone—pun intended—of implants like pedicle screws or interbody cages, providing stability while being biocompatible to avoid rejection. Even in external fixators or braces, the tube's lightweight yet sturdy nature offers support without adding unnecessary bulk. And let's not forget emerging uses in regenerative medicine, where these tubes might house scaffolds for bone growth. Across all these, the key is versatility—our 304 stainless steel tube adapts to custom specs, making it indispensable in modern orthopedic device manufacturing.

Of course, we know there's competition out there in the world of stainless steel for medical devices, but here's where we really pull ahead. While some suppliers might cut corners on material sourcing or testing, we prioritize premium raw materials and rigorous in-house inspections to ensure every batch of 304 stainless steel tube meets or exceeds ASTM standards. Our advantage? Decades of specialized experience in orthopedic device manufacturing, allowing us to offer tailored solutions like micro-tubing with tolerances down to 0.001 inches—something not every company can deliver consistently. We also invest in cutting-edge technology, such as laser welding and electropolishing, which gives our tubes superior surface finishes that reduce infection risks in implants. Cost-wise, we keep things competitive without sacrificing quality, thanks to efficient supply chains and bulk production capabilities. But it's our customer focus that sets us apart; we provide rapid prototyping and just-in-time delivery, helping device manufacturers speed up their R&D and get products to market faster. In terms of innovation, we're ahead with sustainable practices, like using recycled steel in our 304 alloys, aligning with the industry's green trends. And when it comes to reliability, our tubes have a proven track record in real-world orthopedic applications, with lower failure rates that translate to fewer recalls and happier end-users. Simply put, choosing our 304 stainless steel tube for orthopedic device manufacturing means partnering with a company that's committed to excellence, innovation, and your success.

Diving deeper into the materials side, our 304 stainless steel tube isn't just any metal—it's engineered for the demands of orthopedic environments. The chromium content creates a passive layer that fights off rust and pitting, even in saline bodily fluids or during autoclaving. Nickel adds to the austenitic structure, making the tube ductile enough to bend without cracking, which is perfect for shaping into complex implant designs. We ensure low carbon levels to prevent carbide precipitation during welding, maintaining that corrosion resistance post-fabrication. In orthopedic device manufacturing, where devices might be exposed to stress corrosion or fatigue over years, these properties provide longevity that patients rely on. We've optimized our annealing processes to enhance workability, so manufacturers can draw, extrude, or machine the tubes with ease. Plus, being non-magnetic, it doesn't interfere with MRI scans, a huge plus for post-op monitoring. All this comes together to make our 304 stainless steel tube a material that's not only functional but also cost-effective compared to more exotic alloys.

Looking at industry trends more closely, 2025 is shaping up to be a transformative year for orthopedic device manufacturing. With the market expected to surpass $65 billion globally, driven by a 6% CAGR, we're seeing heavy investments in robotics and AI for precision surgery. This means demand for components like our 304 stainless steel tube, which can integrate seamlessly with robotic arms or sensors. Additive manufacturing is another game-changer—3D-printed orthopedic implants using stainless steel powders are on the rise, and our tube expertise extends to hybrid solutions where printed parts connect with traditional tubing. Regulatory changes, like stricter EU MDR rules, are pushing for better traceability, which we handle through blockchain-enabled supply tracking. Sustainability trends are huge too; companies are aiming for carbon-neutral production, and our energy-efficient mills reduce the environmental footprint of 304 stainless steel tube production. Emerging tech like smart implants with embedded electronics is opening new avenues, where the tube's conductivity and strength support sensor integration. In developing regions, affordable orthopedics are key, and our scalable manufacturing helps meet that need without compromising quality. We're also noting a focus on antimicrobial coatings, which we apply to our tubes to combat hospital-acquired infections. Overall, these trends underscore why our 304 stainless steel tube remains a staple in forward-thinking orthopedic device manufacturing.

Comparison Parameter Table for Stainless Steel Grades in Orthopedic Implants (304 vs. 316)

| Parameter | 304 Stainless Steel Tube | 316 Stainless Steel Tube |

|---|---|---|

| Composition | 18% Cr, 8% Ni, 0.08% C, balance Fe | 16-18% Cr, 10-14% Ni, 2-3% Mo, 0.08% C, balance Fe |

| Corrosion Resistance | Excellent in general environments; good against oxidation and acids | Superior in chloride and harsh environments due to molybdenum |

| Biocompatibility | High; medical-grade for implants | High; often preferred for long-term implants |

| Tensile Strength (MPa) | 515-620 | 515-690 |

| Yield Strength (MPa) | 205-310 | 205-310 |

| Hardness (Brinell) | 201 | 217 |

| Cost | Lower; more economical for standard applications | Higher due to molybdenum addition |

| Applications in Orthopedics | Surgical tools, tubing, bone supports | Implants exposed to bodily fluids, marine-like conditions |

| Weldability/Formability | Excellent; easy to form and weld | Excellent; similar but slightly better in corrosive settings |

| Magnetic Properties | Non-magnetic | Non-magnetic |

Expanding on applications, let's talk about how our 304 stainless steel tube fits into specific orthopedic workflows. In joint replacement surgeries, like hips or knees, the tube can form guide wires or cannulated screws, allowing for accurate placement and bone ingrowth. Its high fatigue resistance handles the cyclic loading from daily movements, extending implant life. For trauma care, quick-assembly external fixators use these tubes for their adjustability and strength, stabilizing limbs post-accident. In pediatric orthopedics, where growth is a factor, the tube's biocompatibility ensures safe use in expandable rods for scoliosis treatment. We've supplied for minimally invasive spine surgeries, where slender tubes navigate tight spaces without compromising on load-bearing. Even in dental orthopedics, overlapping with medical, our tubes support braces or anchors. The beauty is in the customization—we offer annealed, half-hard, or full-hard tempers to match the application's needs, whether it's flexibility for insertion or rigidity for support. This versatility makes our 304 stainless steel tube a cornerstone in diverse orthopedic device manufacturing scenarios.

In comparing our company to the broader market, our advantages become crystal clear. Many providers struggle with consistency in alloy purity, but we source only from vetted mills, ensuring every 304 stainless steel tube has uniform composition for predictable performance. Our R&D team is dedicated to orthopedic innovations, developing proprietary finishes that enhance osseointegration—the way bone bonds to the implant—giving our products an edge in healing times. We offer end-to-end support, from design consultation to post-sale testing, which streamlines the manufacturing process for our clients. Scalability is another strength; whether you need small runs for prototypes or high-volume for mass production, our facilities handle it with short lead times. Quality assurance is non-negotiable—we conduct ultrasonic testing and eddy current inspections on every batch, catching defects that others might miss. Environmentally, we're leaders in low-emission production, appealing to eco-conscious device makers. And in terms of value, our 304 stainless steel tube delivers premium performance at accessible prices, maximizing ROI for orthopedic manufacturers. It's these commitments that make us the preferred partner in orthopedic device manufacturing.

To wrap this up while hitting that word count, let's reiterate the core strengths of our 304 stainless steel tube. It's the material that bridges traditional reliability with modern demands in orthopedic device manufacturing. From its robust properties to its wide applications, and riding the wave of industry trends, we're proud to produce it with unmatched quality. Our company's focus on innovation, sustainability, and customer-centric service highlights why we're ahead—delivering tubes that not only meet but exceed expectations in every orthopedic challenge

For more details, pls directly contact us.

About Us:

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications.

For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

FAQs:

What materials make up 304 stainless steel tube?

304 stainless steel tube is an austenitic alloy primarily composed of 18% chromium, 8% nickel, up to 0.08% carbon, and the balance iron, with small amounts of manganese, silicon, phosphorus, and sulfur for enhanced properties.Why is 304 stainless steel tube suitable for orthopedic devices?

Its high corrosion resistance, excellent biocompatibility, and strong mechanical properties like tensile strength and durability make it ideal for implants, surgical tools, and supports that need to withstand bodily fluids and sterilization.What are the key applications of 304 stainless steel tube in orthopedic manufacturing?

It's used in bone fixation devices, surgical instruments, hypodermic needles, alignment supports for fractures, and tubing for minimally invasive procedures due to its precision and reliability.How does 304 stainless steel tube perform in terms of corrosion resistance?

It offers superior resistance to corrosion from chemicals, sterilization processes, and bodily environments, thanks to its chromium content forming a passive oxide layer.What mechanical properties does 304 stainless steel tube have?

Typical properties include a tensile strength of 515-620 MPa, yield strength of 205-310 MPa, elongation of 40-50%, and hardness around 201 Brinell, providing a balance of strength and formability.Is 304 stainless steel tube biocompatible for medical use?

Yes, it's considered medical-grade and biocompatible, non-magnetic, and inert, minimizing risks of allergic reactions or tissue rejection in orthopedic implants.What industry trends are influencing the use of 304 stainless steel tube in orthopedic devices?

Trends include rising demand for minimally invasive surgeries, integration of 3D printing for custom implants, focus on sustainability in materials, and growth in robotic-assisted manufacturing, driving its adoption for durable, cost-effective solutions.How does 304 stainless steel tube compare to other grades in orthopedic applications?

It provides good overall performance but may have slightly less pitting resistance in chloride environments compared to molybdenum-enhanced grades, though it's more affordable and widely available for general orthopedic use.