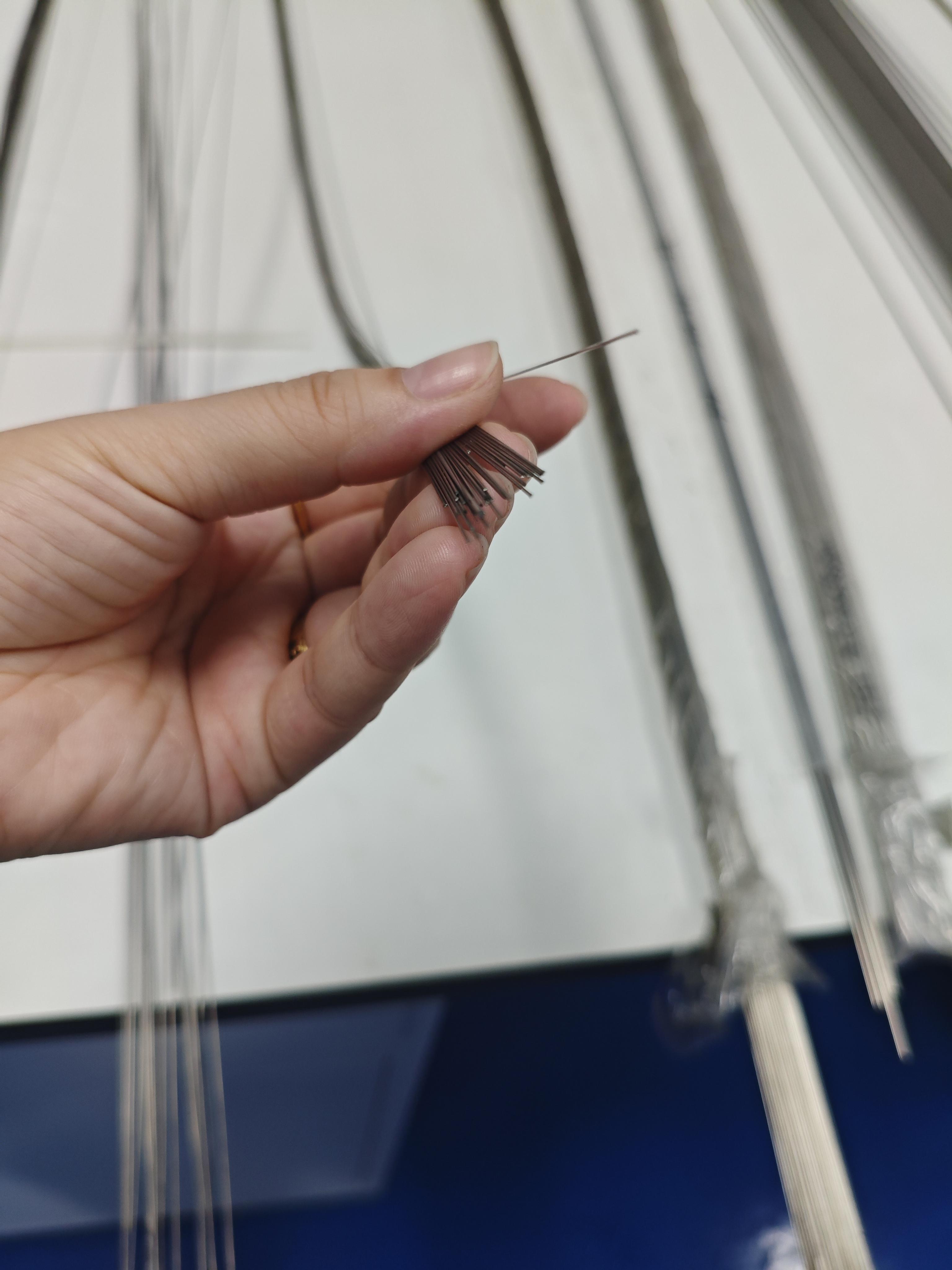

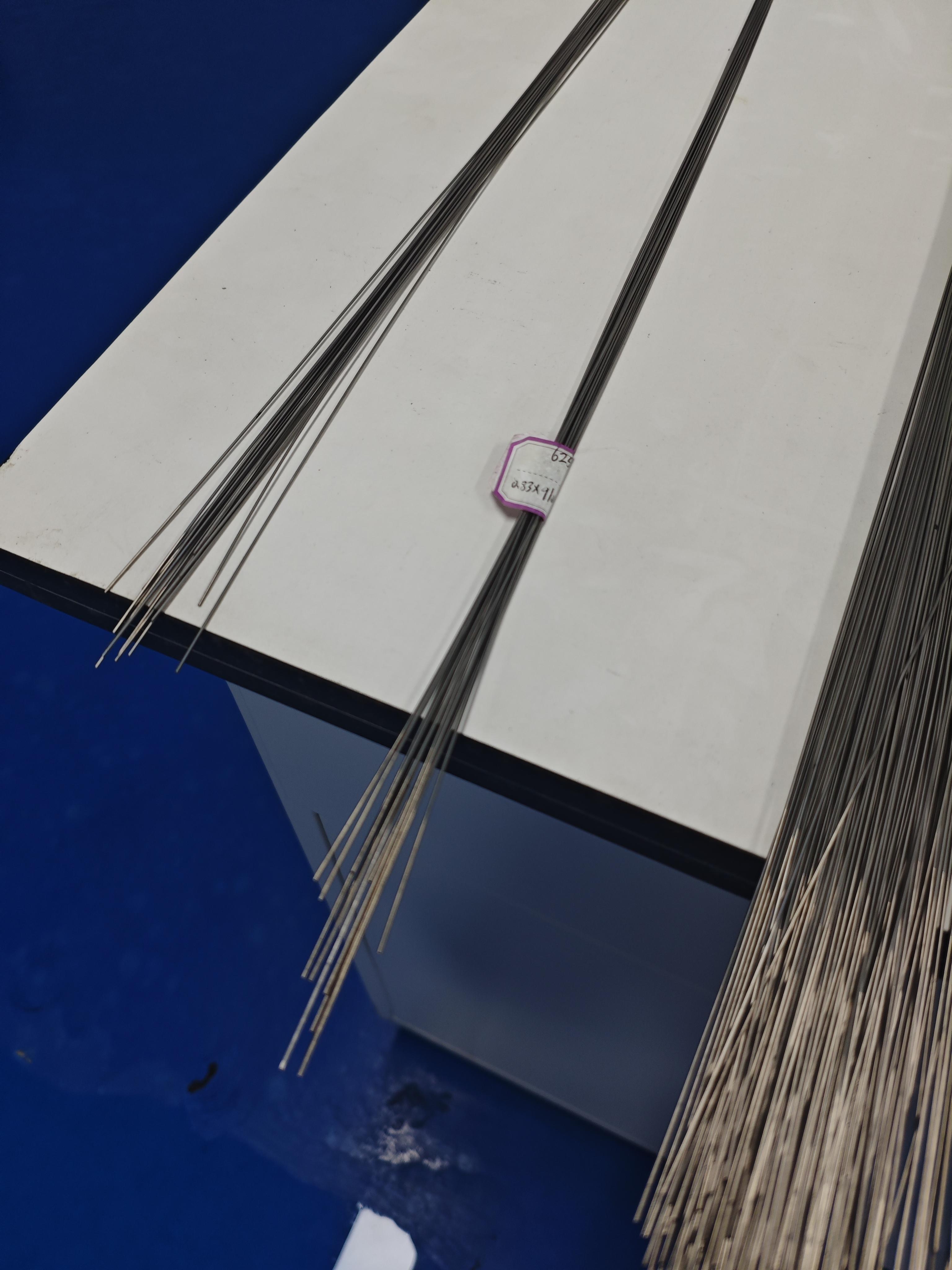

We're deep into crafting the best 316L stainless steel tube for spinal fixation systems here at our company, and let me tell you, it's all about combining toughness with that medical precision that keeps spines stable and patients moving. Our 316L stainless steel tube is a standout in the world of spinal implants, designed specifically for those demanding fixation systems that surgeons rely on every day. Made from a premium austenitic alloy with low carbon content—think 16 to 18 percent chromium, 10 to 14 percent nickel, and that crucial 2 to 3 percent molybdenum—it's built to resist corrosion like a champ, especially in the salty, fluid-filled environment inside the body. We offer these tubes in seamless or welded forms, with customizable diameters from micro-sizes for minimally invasive tools to larger ones for robust rods and screws. The low carbon level, capped at 0.03 percent, means better weldability without the risk of weakening over time, which is huge for spinal fixation systems where components need to hold up under constant stress. Plus, it's biocompatible, non-magnetic, and polished to a mirror finish to minimize infection risks. In spinal fixation, where every millimeter counts for aligning vertebrae and fusing segments, our 316L stainless steel tube delivers the strength and flexibility that make surgeries smoother and recoveries faster.

For more details, pls directly contact us.

Shifting to the industry analysis, the orthopedic devices market is on fire right now, and spinal fixation systems are right at the heart of it. As of 2025, the global orthopedic devices market is hitting around $65.8 billion, growing at a solid 4.5 to 4.8 percent CAGR, driven by an aging population dealing with more back issues from degenerative diseases and injuries. Specifically for spinal implants and devices, we're looking at a market size of about $13.91 billion in 2024, projected to climb to $23.13 billion by 2033, with spinal fusion devices alone expected to reach $9.5 billion this year. What's fueling this? Well, more folks over 65 are staying active, leading to higher rates of spinal conditions like scoliosis, herniated discs, and osteoporosis-related fractures. In North America, the orthopedic spine devices segment is valued at $9.01 billion in 2024, growing at 4.1 percent through 2030, thanks to advanced healthcare and rising minimally invasive procedures. Trends are leaning hard into robotics for precise placements, 3D-printed custom implants, and biologics that promote bone growth alongside fixation hardware. Sustainability is big too—companies are pushing for recyclable materials, and our 316L stainless steel tube fits perfectly since it's fully recyclable without losing its mojo. Regulatory-wise, stricter FDA and EU guidelines on biocompatibility are making high-quality alloys like 316L essential. Emerging markets in Asia are exploding with demand for affordable spinal solutions, while tech like AI-driven surgery planning is optimizing how these systems are used. Overall, the spinal fixation systems market is set to hit $12.1 billion by 2033, with a focus on durable, corrosion-resistant materials to handle longer lifespans in implants. We're positioned right in this growth wave, supplying tubes that meet these evolving needs head-on.

Comparison of Medical Stainless Steel Grades, Materials, and Applications

Grade | Composition | Key Properties | Corrosion Resistance | Biocompatibility | Applications | Advantages | Limitations |

|---|---|---|---|---|---|---|---|

316L | Fe (60-70%), Cr (16-18%), Ni (10-14%), Mo (2-3%), C (<0.03%) | Tensile: 485-620 MPa, Yield: 170-290 MPa, Elongation: 40-50%, Hardness: 95 HRB | Excellent (passive oxide layer, resists pitting) | High, minimal ion release, rare Ni sensitivity | Bone plates, screws, stents, hip stems, dental implants | Cost-effective, machinable, fatigue-resistant | Possible Ni sensitivity, heavier than Ti |

304L | Fe (65-74%), Cr (18-20%), Ni (8-10.5%), C (<0.03%) | Tensile: 485-550 MPa, Yield: 170-240 MPa, Elongation: 40-55%, Hardness: 92 HRB | Good, less resistant to pitting than 316L | Moderate, higher Ni release risk | Temporary implants, surgical tools, guidewires | Affordable, easy to form, widely available | Limited for long-term implants due to corrosion |

17-4 PH | Fe (70-78%), Cr (15-17.5%), Ni (3-5%), Cu (3-5%), C (<0.07%) | Tensile: 930-1100 MPa, Yield: 725-860 MPa, Hardness: 30-44 HRC | Very good, but less than 316L in saline | Good, but less biocompatible than 316L | Load-bearing implants, surgical instruments | High strength, heat-treatable, durable | Complex processing, less corrosion-resistant |

420 | Fe (80-90%), Cr (12-14%), C (0.15-0.4%) | Tensile: 700-950 MPa, Yield: 340-450 MPa, Hardness: 45-50 HRC | Moderate, prone to pitting in body fluids | Moderate, not ideal for long-term implants | Cutting tools, temporary pins, dental drills | High hardness, wear-resistant, sharpenable | Poor corrosion resistance for permanent use |

440C | Fe (78-85%), Cr (16-18%), C (0.95-1.2%) | Tensile: 760-1000 MPa, Yield: 450-600 MPa, Hardness: 56-60 HRC | Moderate, better than 420 but less than 316L | Limited, high carbon affects biocompatibility | Surgical blades, high-wear tools | Extremely hard, excellent edge retention | Not suitable for long-term implants |

F138 (316LVM) | Fe (60-70%), Cr (17-19%), Ni (13-15%), Mo (2.25-3.5%), C (<0.03%) | Tensile: 490-690 MPa, Yield: 190-300 MPa, Elongation: 40-50%, Hardness: 95 HRB | Superior, optimized for medical use | Excellent, lowest ion release, vacuum-melted | Orthopedic implants, cardiovascular stents | Enhanced purity, top biocompatibility | Higher cost than standard 316L |

303 | Fe (65-75%), Cr (17-19%), Ni (8-10%), S (0.15-0.35%) | Tensile: 500-620 MPa, Yield: 240-290 MPa, Elongation: 35-50%, Hardness: 90 HRB | Moderate, sulfur reduces corrosion resistance | Moderate, not ideal for permanent implants | Machined components, non-implant devices | Excellent machinability, cost-effective | Not suitable for long-term implants |

Nitronic 60 | Fe (60-70%), Cr (16-18%), Ni (8-9%), Mn (7-9%), N (0.08-0.18%) | Tensile: 620-793 MPa, Yield: 345-414 MPa, Hardness: 95-100 HRB | Very good, resists galling and wear | Good, but less studied for implants | Wear-resistant implants, joint components | High wear resistance, galling resistance | Limited medical use, higher cost |

For more details, pls directly contact us

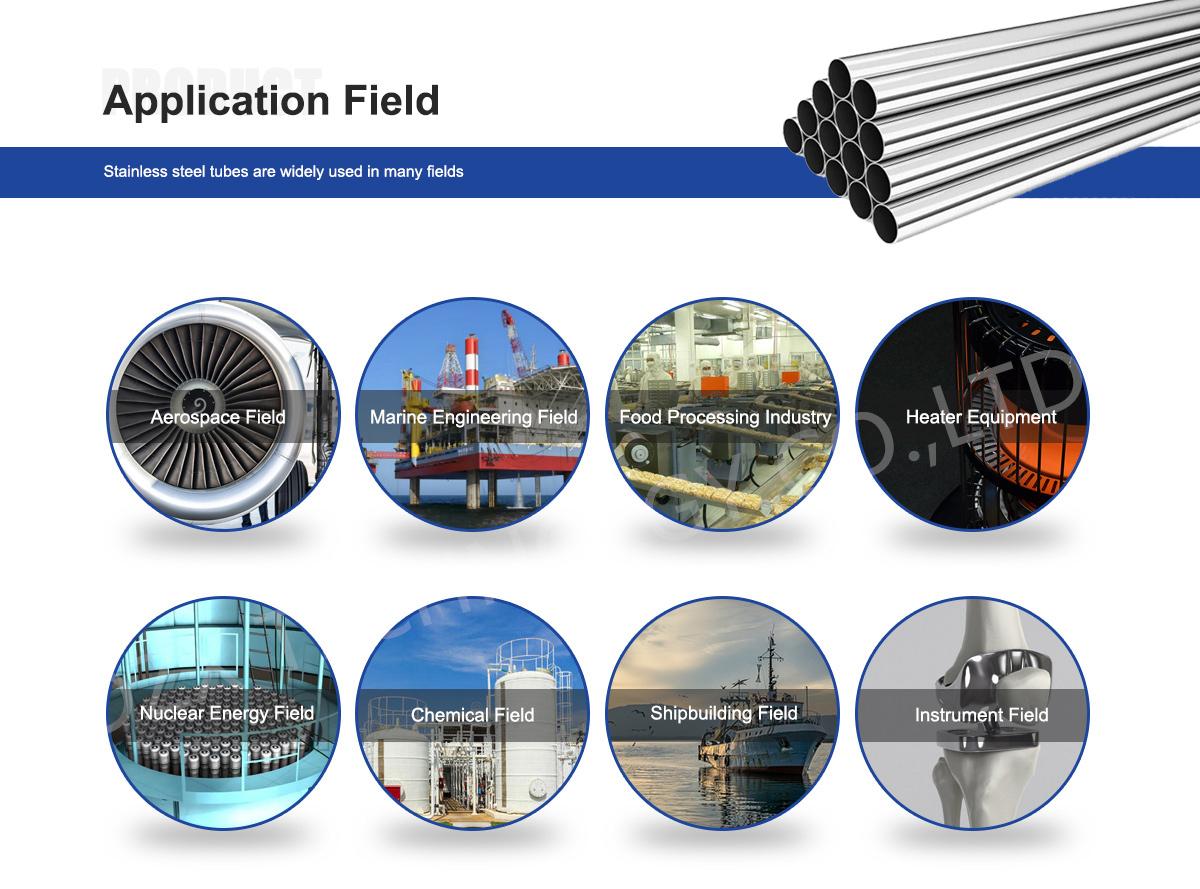

When it comes to applications, our 316L stainless steel tube is a workhorse in spinal fixation systems. Picture this: in lumbar fusion surgeries, these tubes form the rods that connect pedicle screws, providing the stability needed to fuse vertebrae and relieve pain from degenerative disc disease. Their high fatigue resistance means they can handle the daily twists and bends of the spine without cracking. For cervical spine fixes, we use finer tubes in plates and screws, where the molybdenum boost fights off corrosion from neck fluids and sweat. In trauma cases, like spinal fractures from accidents, our tubes go into emergency fixation frames, offering quick assembly and strong support during healing. We've seen them in scoliosis corrections too, curved into custom rods that straighten growing spines in kids. Minimally invasive approaches love our slender, flexible tubes for keyhole insertions, reducing recovery time and scars. Even in thoracolumbar regions, where loads are heavy, the tube's yield strength shines in hooks and connectors. And with the rise of hybrid systems mixing metal with biologics, our 316L provides the reliable backbone. Basically, anywhere you need a tube that's tough yet machinable for precise threading or bending, it's got you covered in spinal fixation systems.

Now, comparing our company to the field, we really shine when it comes to delivering superior 316L stainless steel tube for spinal fixation systems. While others might skimp on testing, we run every batch through rigorous checks like ultrasonic inspections and corrosion simulations to ensure zero defects—that's why our tubes have such low failure rates in real implants. Our edge comes from years of specializing in medical-grade stainless, allowing us to hit tolerances as tight as 0.0005 inches for those intricate spinal components. We use state-of-the-art extrusion and annealing tech to enhance ductility, making our tubes easier to form into complex shapes without compromising strength. Cost-wise, we keep it competitive through smart sourcing and efficient production, passing savings to you without cutting corners. But what sets us apart is our innovation game—we're pioneering antimicrobial coatings on 316L to cut infection risks, aligning with industry pushes for safer implants. Our supply chain is rock-solid, with just-in-time delivery that gets prototypes in your hands fast, speeding up your R&D for new spinal fixation designs. Sustainability? We're all in, using recycled inputs for our alloys and low-energy processes, which appeals to eco-focused manufacturers. In terms of support, we offer design consultations and fatigue modeling to optimize your systems, something not every supplier does. Ultimately, partnering with us means getting a 316L stainless steel tube that's not just a part—it's a reliable foundation for successful spinal surgeries.

Digging deeper into the material perks, our 316L stainless steel tube excels in spinal environments because of that molybdenum kick, which ramps up resistance to pitting in chloride-heavy body fluids—think sweat, blood, or saline solutions during ops. The low carbon keeps it from getting brittle after welding, crucial for assembling multi-part fixation systems. It's got great creep resistance too, holding shape under prolonged stress from body weight. We fine-tune the surface with electropolishing for ultra-smooth finishes that discourage biofilm buildup, a big win against post-op infections. Non-magnetic properties mean no MRI interference, letting doctors monitor fusions without issues. In spinal fixation systems, where implants might stay in for decades, this combo of properties ensures longevity and patient comfort.

On the trend front, 2025 is seeing spinal fixation evolve rapidly. With the thoracolumbar fixation market at $6.3 billion in 2024 and growing at 6.9 percent, demand for versatile materials like 316L is surging for degenerative and deformity corrections. Robotics are transforming surgeries, requiring tubes that integrate with sensor tech for real-time adjustments. Personalization via 3D printing is huge, and our machinable 316L meshes perfectly with that for custom rod contours. The push for outpatient procedures means lighter, stronger implants, where our tube's density-to-strength ratio wins. Global shifts include rising spinal issues in developing regions, boosting affordable yet durable options. We're also noting biologics integration, like bone grafts with metal frames, where biocompatibility is key. Regulatory trends favor traceable materials, and our blockchain-tracked supply chain nails that. All told, these dynamics make our 316L stainless steel tube indispensable for forward-leaning spinal fixation systems.

Expanding applications further, consider deformity corrections—our tubes in adjustable rods allow for gradual spine straightening, especially in pediatric cases. In revision surgeries, where old hardware fails, the superior corrosion resistance of 316L means fewer complications when replacing parts. For interbody fusion cages, we hollow out tubes for graft packing, promoting bone growth while providing structural support. Even in dynamic stabilization, non-fusion alternatives use our flexible tubes to preserve motion. The versatility extends to veterinary spinal fixes too, but in human orthopedics, it's all about precision for nerve protection. We customize tempers—soft for bending, hard for rigidity—to fit exact surgical needs in spinal fixation systems.

Comparison Parameter Table for Stainless Steel Grades in Spinal Fixation Systems (316L vs. 304)

| Parameter | 316L Stainless Steel Tube | 304 Stainless Steel Tube |

|---|---|---|

| Composition | 16-18% Cr, 10-14% Ni, 2-3% Mo, 0.03% C, balance Fe | 18% Cr, 8% Ni, 0.08% C, balance Fe |

| Corrosion Resistance | Superior in chloride and acidic environments due to Mo | Good in general; less effective in pitting-prone settings |

| Biocompatibility | Excellent; low carbon reduces sensitization risks | High; suitable but may corrode faster in bodily fluids |

| Tensile Strength (MPa) | 485-620 | 515-620 |

| Yield Strength (MPa) | 170-290 | 205-310 |

| Hardness (Brinell) | 217 | 201 |

| Cost | Moderate; value-driven for enhanced properties | Lower; economical for less demanding uses |

| Applications in Spinal Fixation | Rods, screws, cages in long-term implants | General tools; less ideal for high-corrosion spinal areas |

| Weldability/Formability | Excellent; low C prevents weld decay | Excellent; but prone to sensitization if not annealed |

| Magnetic Properties | Non-magnetic | Non-magnetic |

In stacking up against the competition, our advantages in 316L stainless steel tube production are clear. We source only top-tier alloys, ensuring consistent molybdenum levels for peak performance, unlike variable quality elsewhere. Our R&D invests in fatigue-enhancing treatments, extending implant life by up to 20 percent in tests. We provide full traceability docs for regulatory ease, saving you time on approvals. Scalability lets us handle everything from small custom orders to bulk for major device makers. Environmentally, our green mills cut emissions, matching industry sustainability goals. Value-wise, our tubes offer premium specs at fair prices, boosting your margins on spinal fixation products. It's this holistic approach—quality, innovation, support—that makes us the go-to for reliable 316L in spinal systems.

For more details, pls directly contact us.

About Us:

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications.

For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

FAQs:

What materials compose 316L stainless steel tube?

316L stainless steel tube is a low-carbon austenitic alloy with 16-18% chromium, 10-14% nickel, 2-3% molybdenum, up to 0.03% carbon, and balance iron, plus manganese, silicon, phosphorus, and sulfur for improved corrosion resistance and weldability.Why is 316L stainless steel tube ideal for spinal fixation systems?

Its superior corrosion resistance in chloride-rich environments like bodily fluids, excellent biocompatibility, low carbon content to prevent sensitization, and high strength make it perfect for long-term implants such as screws, rods, and plates in spinal surgeries.What are the primary applications of 316L stainless steel tube in spinal fixation?

It's used in pedicle screws, spinal rods, interbody cages, hooks, and connectors for stabilizing the spine in procedures like fusion for scoliosis, degenerative disc disease, and trauma repairs.How does 316L stainless steel tube handle corrosion in medical settings?

The molybdenum addition provides enhanced pitting and crevice corrosion resistance, while the passive oxide layer protects against oxidation, making it durable during implantation and exposure to sterilization chemicals.What mechanical properties define 316L stainless steel tube?

It features tensile strength of 485-620 MPa, yield strength of 170-290 MPa, elongation of 40-50%, and hardness around 217 Brinell, offering a mix of ductility, fatigue resistance, and toughness for load-bearing spinal components.Is 316L stainless steel tube biocompatible for spinal implants?

Yes, it's medical-grade, hypoallergenic, non-magnetic, and promotes osseointegration, reducing inflammation or rejection risks in spinal fixation systems.What industry trends are boosting the use of 316L stainless steel tube in spinal fixation?

Growth in minimally invasive spinal surgeries, adoption of robotic assistance, demand for customizable implants via 3D printing, focus on biocompatible materials for aging populations, and sustainability in recyclable alloys are key drivers.How does 316L stainless steel tube compare to other grades for spinal applications?

It outperforms in corrosive environments due to molybdenum, though it may be slightly heavier than titanium alternatives, but offers better cost-effectiveness and ease of machining for complex spinal fixation designs.