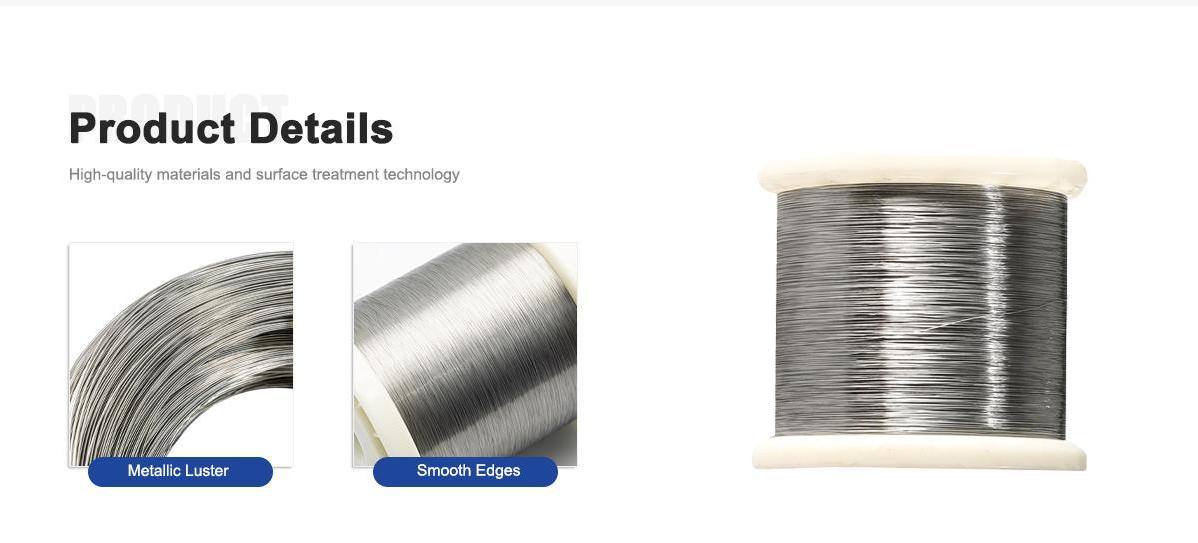

Our N4/Ni201 pure nickel wire, boasting a minimum 99.9% purity, stands as a cornerstone material for industries demanding reliability, durability, and performance. Designed to tackle the toughest environments, this wire is a go-to choice for chemical processing, electronics, and beyond. With its exceptional corrosion resistance, high thermal stability, and top-tier electrical conductivity, it’s no wonder why our product is trusted across multiple sectors. Let’s dive into what makes our N4/Ni201 nickel wire special, explore its applications, analyze industry trends, and highlight why our company leads the pack.

Our N4/Ni201 pure nickel wire is a high-purity, low-carbon nickel alloy engineered for demanding applications. With a nickel content of at least 99.9%, it offers unmatched resistance to corrosive environments, particularly caustic alkalis, chlorine, and neutral salts. Its low carbon content (≤0.02%) ensures it avoids embrittlement at high temperatures, making it suitable for use up to 1230°C without losing structural integrity. Available in diameters ranging from 0.025mm to 8mm, and in forms like wire, strip, or mesh, this product is highly customizable to meet specific project needs.

What sets our nickel wire apart is its ability to perform under pressure—literally and figuratively. It boasts excellent mechanical strength, making it ideal for cold-forming operations, while its high electrical and thermal conductivity makes it a favorite in electronics. Whether it’s used in vacuum devices, chemical filters, or battery components, our N4/Ni201 wire delivers consistent, reliable results. Plus, its weldability and ease of degassing make it a practical choice for manufacturing complex systems.

| Grade | Nickel (Ni)+ Cobalt (Co) | Copper (Cu) | Silicon (Si) | Manganese (Mn) | Carbon (C) | Magnesium (Mg) | Sulfur (S) | Phosphorus (P) | Iron (Fe) |

| 99.9% | ≤0.015 | ≤0.03 | ≤0.002 | ≤0.01 | ≤0.01 | ≤0.001 | ≤0.001 | ≤0.04 | |

| 99.6% | 0.1 | 0.1 | 0.05 | 0.1 | 0.1 | 0.005 | 0.002 | 0.1 |

Physical & Mechanical Properties

| Grades | N4/Ni201 | N6/Ni200 |

| Density | 8.9g/cm³ | 8.9g/cm³ |

| Melting Point | 1455°C | 1445-1470℃ |

| Coefficient of Thermal Expansion | 13.0µm/m·°C | 13.3×10⁻⁶/℃ |

| Thermal Conductivity | 10.1W/m·K | 90.7 W/m·K |

| Electrical Resistivity | 0.103×10⁻⁶Ω·/m (at 20℃) | |

| Electrical Conductivity | 14.6% IACS | |

| Tensile Strength | ≥450MPa | ≥450 MPa |

| Yield Strength | ≥200MPa | ≥150 MPa |

| Elongation at Break | ≥40% | ≥40% |

| Hardness | ≤150 |

The high-purity nickel wire market is on a steady upward trajectory, driven by growing demand in electronics, renewable energy, and chemical processing. According to recent market insights, the global high-purity nickel wire market was valued at USD 1.2 billion in 2024 and is projected to reach USD 2.5 billion by 2033, growing at a CAGR of 9.1%. The Asia Pacific region leads the charge, accounting for roughly 45% of the market share in 2023, fueled by booming electronics and energy sectors. The 99.9% purity segment, which our N4/Ni201 wire falls into, held a 50% market share in 2023, with the 99.95% segment expected to grow fastest due to its use in advanced electronics.

Key drivers include the push for lightweight, high-conductivity materials in industries like aerospace and medical devices. The rise of renewable energy, particularly green hydrogen production, is also boosting demand for nickel wire in applications like electrolytic systems. However, challenges like fluctuating raw material prices and stringent quality regulations persist. Our company stays ahead by maintaining a robust supply chain and adhering to international standards like ISO 9001, ensuring consistent quality and availability.

Emerging trends point to increased adoption in energy storage and electric vehicles (EVs). As battery technology advances, high-purity nickel wire is becoming critical for efficient, durable battery connections. The chemical industry is also seeing growth, with nickel wire playing a key role in processing equipment for sustainable fuels and materials. These trends underscore the versatility and future-proof nature of our N4/Ni201 wire.

Parameter | N4/Ni201 Nickel Wire | Other Nickel Wire (e.g., Ni200) |

|---|---|---|

Purity | ≥99.9% | ≥99.5% |

Carbon Content | ≤0.02% (low, prevents embrittlement) | ≤0.15% (higher, risks graphitization) |

Corrosion Resistance | Excellent (alkalis, chlorine, neutral salts) | Good (less resistant in oxidizing conditions) |

Temperature Resistance | Up to 1230°C | Up to 315°C (limited by graphitization) |

Electrical Conductivity | High (ideal for electronics) | Moderate to high |

Mechanical Strength | Strong, suitable for cold forming | Good, but less suited for prolonged high heat |

Applications | Chemical processing, electronics, aerospace | General industrial, less specialized uses |

Our N4/Ni201 nickel wire shines in a variety of applications, thanks to its unique properties. Here’s where it makes the biggest impact:

Chemical Processing: Its exceptional resistance to caustic alkalis and chlorine makes it a staple in diaphragm electrolytic systems and filters for strong alkali production. It ensures product purity in food processing and synthetic fiber manufacturing, where contamination is a no-go.

Electronics: With high electrical conductivity and low resistivity, our wire is perfect for components like heating elements, resistors, and battery connections. It’s a trusted material in everything from consumer electronics to industrial machinery.

Aerospace and Defense: The wire’s ability to withstand extreme temperatures and corrosive environments makes it ideal for turbine components, missile parts, and other high-stress applications.

Renewable Energy: In green hydrogen production, our nickel wire is used in high-purity nickel mesh for electrolytic systems, improving efficiency and output quality.

Medical Devices: Its corrosion resistance and biocompatibility make it suitable for medical equipment, ensuring safety and reliability in critical applications.

Marine Engineering: The wire’s resistance to seawater corrosion makes it a go-to for shipbuilding and offshore equipment.

This versatility ensures our product meets the needs of industries ranging from high-tech to heavy-duty manufacturing.

Company Comparison and Our Advantages

When it comes to high-purity nickel wire, our company stands out in a crowded market. Unlike others, we focus on delivering a product that combines top-tier quality with unmatched flexibility. Our N4/Ni201 wire is produced with a nickel content of 99.9% or higher, surpassing the 99.5% purity of many competitors’ offerings. This higher purity translates to better corrosion resistance and performance in extreme conditions, giving our customers an edge in demanding applications.

Our manufacturing process is another key differentiator. We use advanced refining, drawing, and heat-treatment techniques to ensure every batch meets strict quality standards. This results in a wire with consistent mechanical properties and no compromise on durability. While others may offer limited customization, we provide a wide range of diameters (0.025mm to 8mm) and forms, from wire to mesh, tailored to your exact specifications.

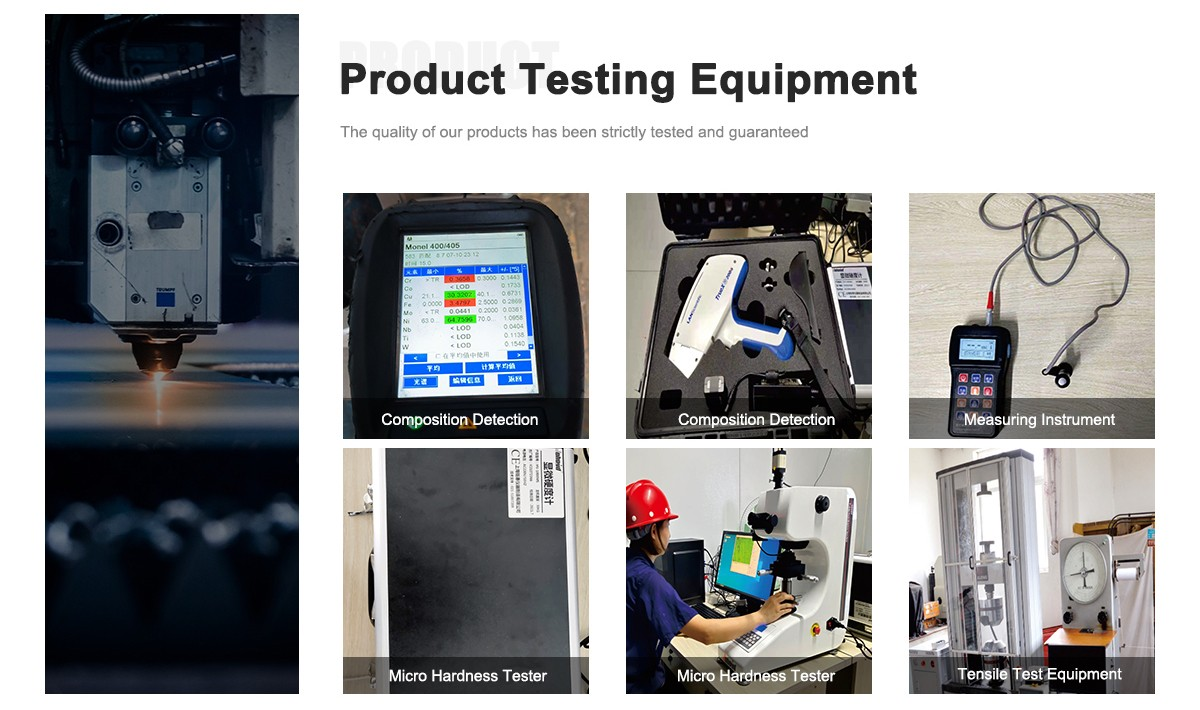

Our supply chain is built for reliability. With years of experience and a global network, we ensure timely delivery, even for large or custom orders. Many in the industry struggle with supply chain disruptions, but our robust logistics keep us ahead. Plus, our ISO 9001 certification and rigorous testing processes guarantee a product you can trust.

We also prioritize customer support. Our team works closely with clients to understand their needs, offering technical guidance and rapid response times. Whether you’re designing a new electronic component or scaling up chemical processing equipment, we’re here to help you succeed. Our flexible pricing and ability to handle both small and large orders make us a partner you can rely on.

Why Choose Our N4/Ni201 Nickel Wire?

Our N4/Ni201 pure nickel wire isn’t just a product—it’s a solution. Its 99.9% purity ensures top performance in corrosive and high-temperature environments, while its versatility makes it a fit for industries from electronics to renewable energy. Here’s why it’s a smart choice:

Superior Corrosion Resistance: Perfect for harsh chemical environments, ensuring long-lasting performance.

High Thermal Stability: Handles temperatures up to 1230°C without losing strength.

Excellent Conductivity: Ideal for electronics, ensuring efficient power transmission.

Customizable Options: Available in various diameters and forms to suit your project.

Reliable Supply Chain: Timely delivery and consistent quality, backed by ISO 9001 certification.

Looking Ahead

As industries evolve, the demand for high-purity nickel wire like our N4/Ni201 is only going to grow. The push for sustainable energy, advanced electronics, and durable materials means our product is well-positioned for the future. We’re committed to staying at the forefront, investing in R&D to enhance our wire’s performance and exploring new applications in emerging fields like EV battery systems and green hydrogen.

In a world where reliability and performance matter, our N4/Ni201 pure nickel wire delivers. Whether you’re building cutting-edge electronics, tackling tough chemical processing challenges, or pushing the boundaries of aerospace, our wire is designed to keep you ahead. Contact us today to see how we can support your next project with a product that’s built to last.

About Us:

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications.

For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

FAQs:

What is N4/Ni201 pure nickel wire?

N4/Ni201 pure nickel wire is a high-purity nickel product (99.9% minimum) with low carbon content, offering excellent corrosion resistance and thermal stability for industrial applications.What are the main applications of N4/Ni201 nickel wire?

It’s widely used in chemical processing, electronics, aerospace, and medical industries for components like heating elements, battery connections, and alkali-resistant equipment.Why is N4/Ni201 preferred for chemical processing?

Its superior resistance to caustic alkalis, chlorine, and other corrosive chemicals makes it ideal for equipment like filters and electrolytic systems in harsh environments.How does N4/Ni201 perform in high-temperature settings?

It maintains mechanical strength and stability up to 1230°C, perfect for high-heat applications like vacuum devices and electronic components.What are the key properties of N4/Ni201 nickel wire?

High corrosion resistance, excellent electrical and thermal conductivity, low resistivity, and good weldability for versatile industrial use.What industries benefit most from N4/Ni201 nickel wire?

Electronics, chemical processing, aerospace, marine engineering, and renewable energy sectors rely on its durability and performance.How does the purity level of N4/Ni201 affect its performance?

The 99.9% purity ensures minimal impurities, enhancing corrosion resistance and reliability in critical applications like battery production and medical devices.Can N4/Ni201 nickel wire be customized?

Yes, it can be tailored in diameters (0.025mm to 8mm) and forms (wire, strip, or mesh) to meet specific project requirements.