Our N6/Ni200 Pure Nickel Wire , with a minimum 99.6% purity, is a game-changer for industries like battery manufacturing and aerospace. Engineered for reliability and performance, this wire combines excellent corrosion resistance, high electrical conductivity, and solid mechanical strength. Whether you’re building next-gen electric vehicle batteries or aerospace components that need to withstand tough conditions, our N6/Ni200 wire is your go-to solution. Let’s break down what makes this product stand out, explore its applications, dive into industry trends, and show why our company leads the way.

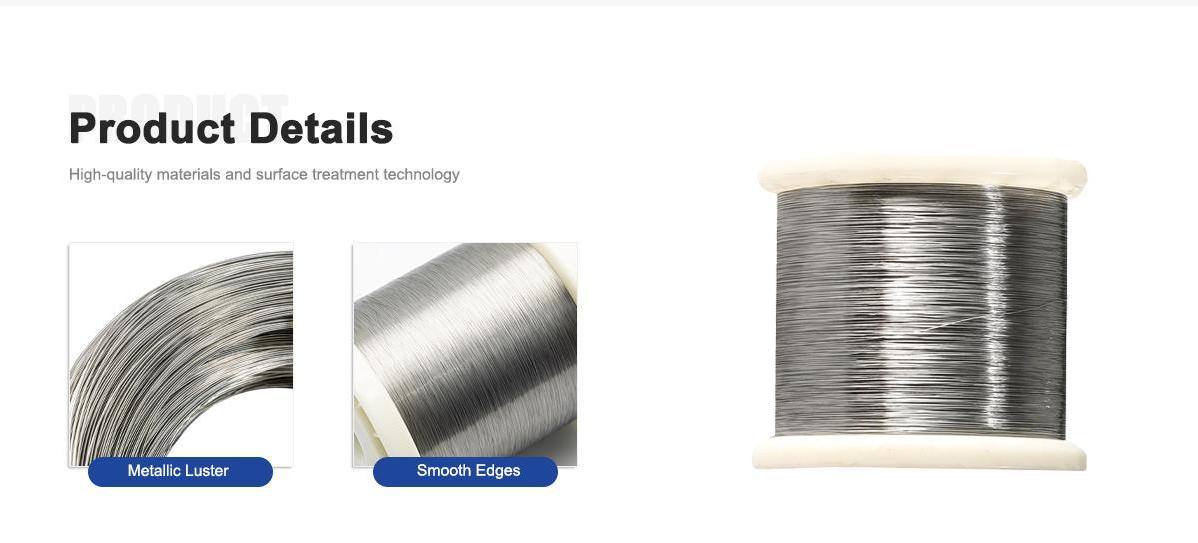

Our N6/Ni200 pure nickel wire is a high-purity nickel alloy designed to meet the demands of cutting-edge industries. With a nickel content of at least 99.6% and a low carbon content (≤0.15%), it’s built to resist corrosion in harsh environments like neutral salts and alkalis. It performs reliably up to 315°C, making it a great fit for applications requiring moderate thermal stability. Available in diameters from 0.025mm to 5mm and in forms like wire, strip, or mesh, this product is highly customizable to suit your specific needs.

What makes our N6/Ni200 wire special is its balance of properties. It offers excellent electrical conductivity, making it ideal for battery manufacturing and electronic components. Its corrosion resistance ensures longevity in challenging environments, while its weldability and formability make it easy to work with in complex designs. From EV battery tabs to aerospace sensors, our wire delivers consistent performance you can count on.

| Grade | Nickel (Ni)+ Cobalt (Co) | Copper (Cu) | Silicon (Si) | Manganese (Mn) | Carbon (C) | Magnesium (Mg) | Sulfur (S) | Phosphorus (P) | Iron (Fe) |

| 99.9% | ≤0.015 | ≤0.03 | ≤0.002 | ≤0.01 | ≤0.01 | ≤0.001 | ≤0.001 | ≤0.04 | |

| 99.6% | 0.1 | 0.1 | 0.05 | 0.1 | 0.1 | 0.005 | 0.002 | 0.1 |

Physical & Mechanical Properties

| Grades | N4/Ni201 | N6/Ni200 |

| Density | 8.9g/cm³ | 8.9g/cm³ |

| Melting Point | 1455°C | 1445-1470℃ |

| Coefficient of Thermal Expansion | 13.0µm/m·°C | 13.3×10⁻⁶/℃ |

| Thermal Conductivity | 10.1W/m·K | 90.7 W/m·K |

| Electrical Resistivity | 0.103×10⁻⁶Ω·/m (at 20℃) | |

| Electrical Conductivity | 14.6% IACS | |

| Tensile Strength | ≥450MPa | ≥450 MPa |

| Yield Strength | ≥200MPa | ≥150 MPa |

| Elongation at Break | ≥40% | ≥40% |

| Hardness | ≤150 |

The high-purity nickel wire market is booming, driven by the rise of electric vehicles, renewable energy, and aerospace advancements. Recent data suggests the global nickel wire market was valued at USD 1.2 billion in 2024 and is expected to hit USD 2.5 billion by 2033, growing at a CAGR of 9.1%. The battery manufacturing segment, a key market for our N6/Ni200 wire, accounted for 40% of demand in 2023, fueled by the global push for EVs and energy storage systems. The Asia Pacific region dominates with a 45% market share, driven by electronics and battery production hubs.

Key trends include the growing need for lightweight, conductive materials in aerospace and the surge in demand for EV batteries, which rely on high-purity nickel for efficient power transfer. Green energy applications, like hydrogen production, are also driving demand for corrosion-resistant materials. Challenges like volatile nickel prices and strict quality standards exist, but our company stays ahead with a reliable supply chain and adherence to ISO 9001 standards, ensuring consistent quality and availability.

Looking forward, the shift toward sustainable technologies is a big opportunity. The EV market is projected to grow at a CAGR of 22% through 2030, increasing the need for high-performance materials like our N6/Ni200 wire. Aerospace is also evolving, with demand for lightweight, durable components rising as space exploration and defense projects expand. Our wire is well-positioned to meet these needs, offering a blend of performance and reliability.

Applications of N6/Ni200 Pure Nickel Wire

Our N6/Ni200 nickel wire is a versatile material that shines in a range of applications. Here’s where it makes a difference:

Battery Manufacturing: Its high electrical conductivity and corrosion resistance make it ideal for battery tabs, connectors, and current collectors in lithium-ion and nickel-based batteries for EVs and energy storage.

Aerospace: The wire’s strength and stability up to 315°C make it perfect for sensors, wiring, and components in aircraft and spacecraft, where reliability is critical.

Electronics: With excellent conductivity, it’s used in heating elements, resistors, and circuit components for consumer and industrial electronics.

Chemical Processing: Its resistance to alkalis and neutral salts makes it a go-to for equipment like filters and reactors in chemical plants.

Renewable Energy: The wire supports green technologies, such as hydrogen production systems, where it’s used in electrolytic setups for durability and efficiency.

Marine Applications: Its corrosion resistance to seawater makes it suitable for marine equipment and offshore installations.

This versatility ensures our N6/Ni200 wire meets the needs of industries pushing the boundaries of technology and sustainability.

Comparison Parameters Table

Parameter | N6/Ni200 Nickel Wire | Other Nickel Alloys |

|---|---|---|

Purity | ≥99.6% | ≥99.0%–99.5% |

Carbon Content | ≤0.15% | ≤0.25% (higher risk of embrittlement) |

Corrosion Resistance | Excellent (neutral salts, alkalis) | Moderate (less resistant in some conditions) |

Temperature Resistance | Up to 315°C | Varies, often lower (~200°C–300°C) |

Electrical Conductivity | High (ideal for battery applications) | Moderate |

Mechanical Strength | Good, suitable for forming and welding | Varies, often less durable |

Applications | Battery manufacturing, aerospace, electronics | General industrial, less specialized |

Customization Range | 0.025mm–5mm, wire/strip/mesh | 0.05mm–3mm, limited forms |

In the world of high-purity nickel wire, our company sets the standard. Our N6/Ni200 wire, with its 99.6% purity, outperforms many alternatives that hover around 99.0%–99.5% purity. This higher purity means better corrosion resistance and electrical performance, critical for applications like EV batteries and aerospace components. While others may cut corners, we prioritize quality at every step.

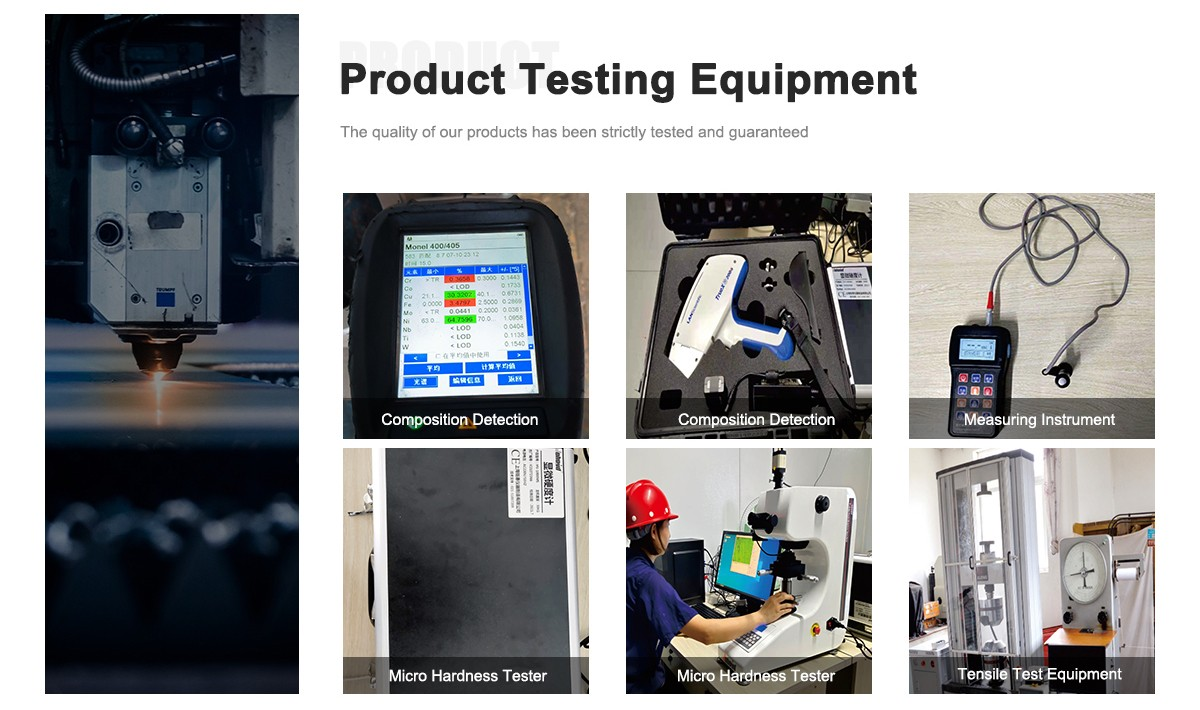

Our manufacturing process is a key advantage. Using state-of-the-art refining, drawing, and quality control techniques, we produce wire with consistent properties and no compromises on durability. Unlike others with limited customization, we offer a wide range of diameters (0.025mm to 5mm) and forms like wire, strip, or mesh, tailored to your exact specifications.

Reliability is at the core of our operations. Our global supply chain ensures timely delivery, even for large or custom orders, while many in the industry struggle with disruptions. Our ISO 9001 certification and rigorous testing processes guarantee a product you can trust. Plus, our customer support team is always ready to provide technical guidance, helping you integrate our wire into your projects seamlessly.

We also offer flexible pricing and the ability to handle orders of any size, from small prototypes to large-scale production runs. This makes us a partner you can rely on, whether you’re a startup or an industry giant.

Why Choose Our N6/Ni200 Nickel Wire?

Our N6/Ni200 pure nickel wire is built to perform. Its 99.6% purity delivers excellent corrosion resistance and conductivity, while its versatility makes it a fit for everything from EV batteries to aerospace systems. Here’s why it’s the right choice:

High Conductivity: Perfect for battery and electronic applications, ensuring efficient power transfer.

Corrosion Resistance: Stands up to harsh environments like alkalis and seawater.

Moderate Thermal Stability: Reliable up to 315°C for aerospace and industrial uses.

Customizable Forms: Available in wire, strip, or mesh to meet your needs.

Dependable Supply: Backed by a robust supply chain and ISO 9001 standards.

Looking to the Future

The future is bright for our N6/Ni200 pure nickel wire. With the EV market booming and aerospace pushing new frontiers, demand for high-purity, high-performance materials is only going up. We’re committed to staying ahead, investing in R&D to enhance our wire’s capabilities and exploring new applications in areas like green hydrogen and advanced electronics.

Our N6/Ni200 wire isn’t just a product—it’s a solution for industries shaping the future. Whether you’re powering the next generation of EVs or building cutting-edge aerospace systems, our wire delivers the performance and reliability you need. Reach out today to see how we can support your projects with a material that’s built to excel.

About Us:

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications.

For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

FAQs:

What is N6/Ni200 pure nickel wire?

N6/Ni200 pure nickel wire is a high-purity nickel product (99.6% minimum) with excellent corrosion resistance and electrical conductivity, designed for battery manufacturing and aerospace applications.What are the primary uses of N6/Ni200 nickel wire?

It’s used in battery manufacturing, aerospace components, electronics, and chemical processing for applications like battery tabs, heating elements, and corrosion-resistant parts.Why is N6/Ni200 ideal for battery manufacturing?

Its high electrical conductivity and corrosion resistance make it perfect for battery tabs and connectors, ensuring efficient power transfer and durability.How does N6/Ni200 perform in aerospace applications?

It offers excellent mechanical strength and stability up to 315°C, making it suitable for aerospace components like sensors and wiring in harsh environments.What are the key properties of N6/Ni200 nickel wire?

High corrosion resistance, excellent electrical conductivity, good weldability, and moderate thermal stability for diverse industrial uses.Which industries benefit from N6/Ni200 nickel wire?

Battery manufacturing, aerospace, electronics, renewable energy, and marine industries rely on its performance and reliability.How does the 99.6% purity level impact its performance?

The 99.6% purity ensures low impurities, improving corrosion resistance and electrical performance, especially in critical applications like EV batteries.Can N6/Ni200 nickel wire be customized?

Yes, it’s available in diameters from 0.025mm to 5mm and in forms like wire, strip, or mesh to meet specific project requirements.