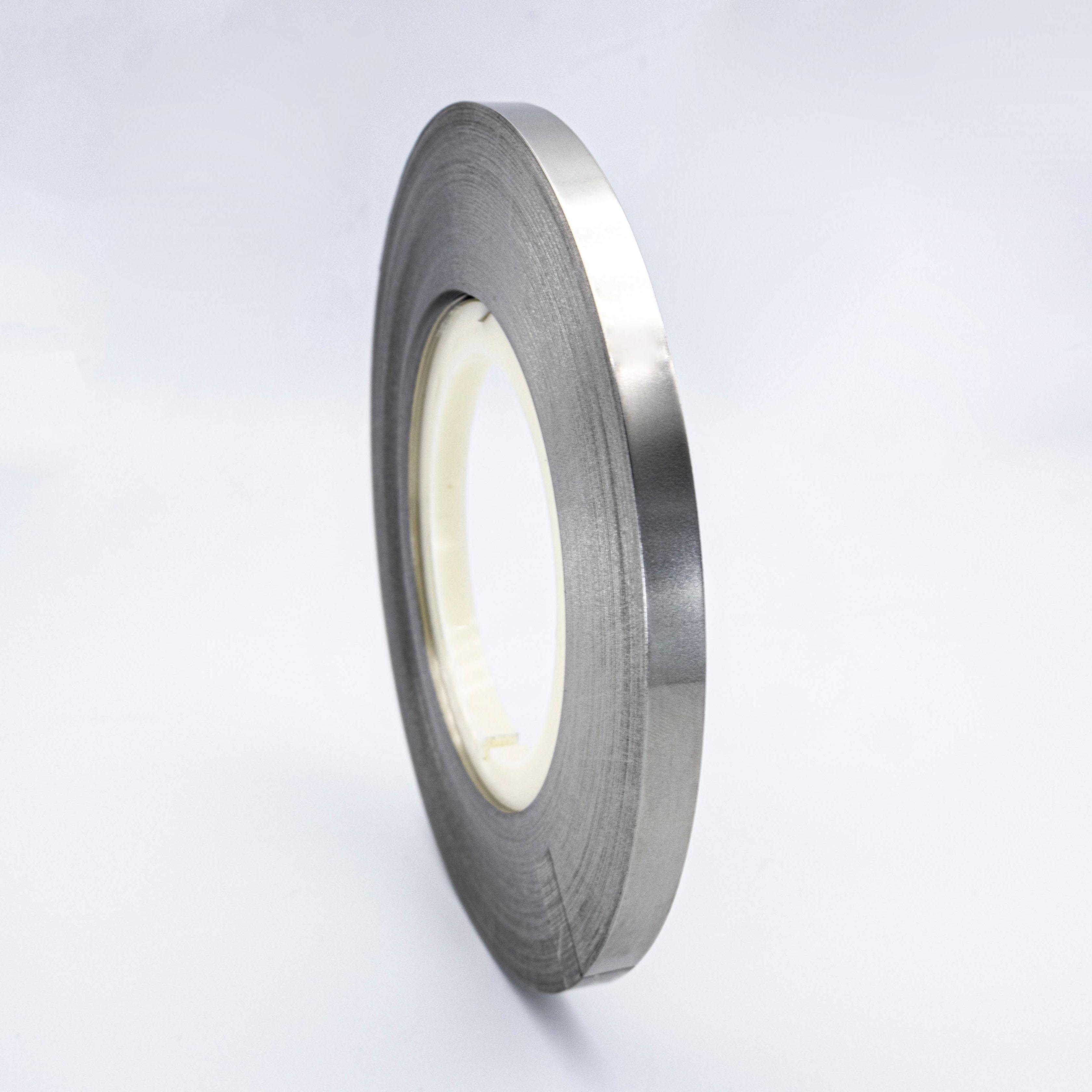

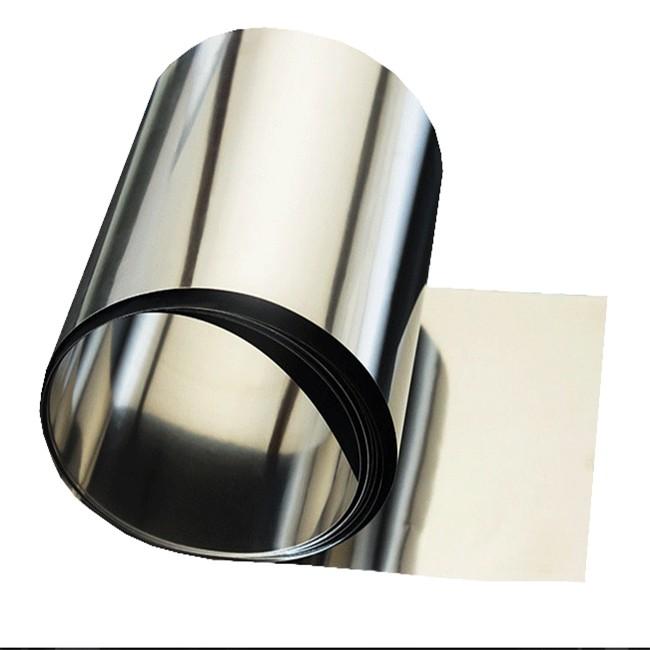

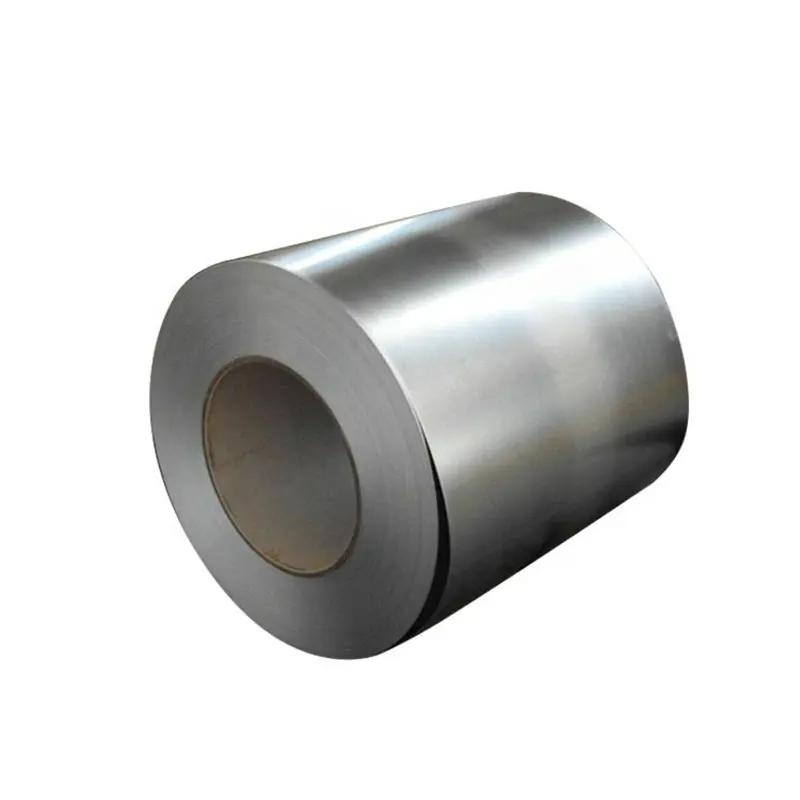

Our thin Titanium Foil sheets are a game-changer for electronics and battery components, crafted from high-quality Grade 2 titanium. With thicknesses as low as 0.01 mm, these sheets are lightweight, corrosion-resistant, and built to meet the demands of cutting-edge tech. Compliant with ASTM B265 standards, they’re perfect for applications where precision and durability are non-negotiable, like battery electrodes, circuit board shielding, and sensor components. Our foil delivers the kind of performance that powers the next generation of electronic devices and energy storage systems.

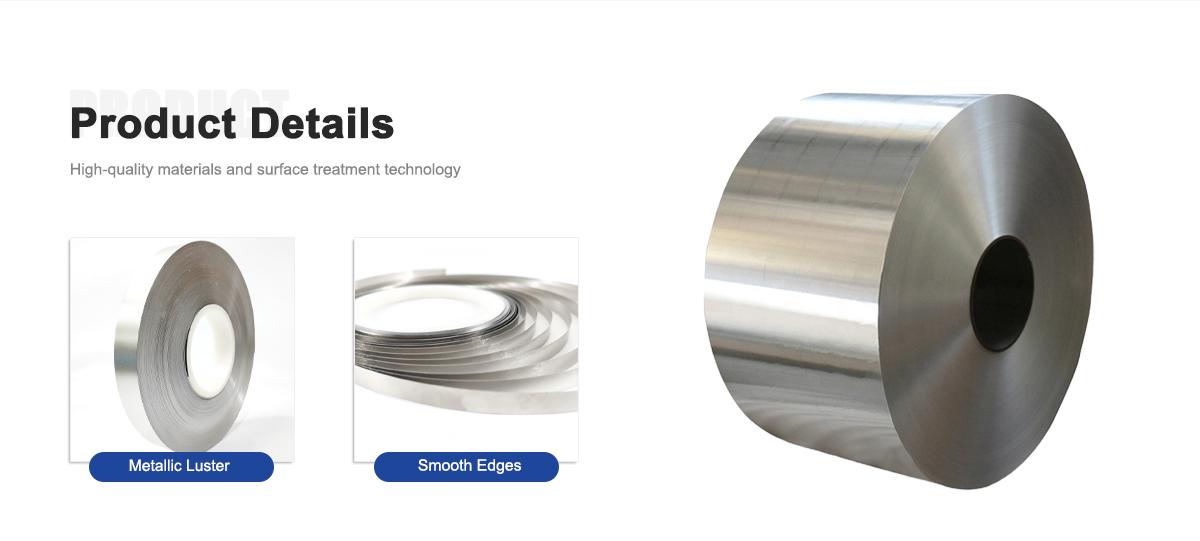

We produce these sheets using advanced cold-rolling techniques, ensuring a smooth, uniform surface that’s ideal for intricate designs. At a density of 4.51 g/cm³, they’re 45% lighter than steel, yet their tensile strength of ~345 MPa ensures they hold up under stress. Their natural corrosion resistance makes them a top pick for environments exposed to moisture or chemicals, while their conductivity suits high-performance electronics. We’ve dialed in our manufacturing to deliver consistent quality, so you get reliable results every time.

For more details, pls directly contact us.

Our thin titanium foil sheets are made from commercially pure Grade 2 titanium, with 99.2% titanium content and minimal alloying elements. This purity gives them a killer combo of low weight, solid strength, and excellent formability. With a density of 4.51 g/cm³, they’re perfect for weight-sensitive electronics. Their tensile strength of ~345 MPa strikes a balance between durability and flexibility, making them easy to shape into precise components. The foil’s natural oxide layer protects against corrosion from moisture, acids, and salts, ensuring longevity in harsh conditions. It’s also thermally stable up to 400°C and offers decent electrical conductivity, making it a go-to for battery and electronic applications.

Applications

Our thin titanium foil sheets are built for electronics and battery components but shine in a range of uses:

Battery Electrodes: Lightweight and conductive, perfect for lithium-ion and next-gen battery systems.

Circuit Board Shielding: Protects sensitive electronics from electromagnetic interference.

Sensors: Used in precision sensors for their corrosion resistance and durability.

Flexible Electronics: Ideal for wearable devices and foldable screens due to their thinness and flexibility.

Connectors: Ensures reliable conductivity in high-performance electronic systems.

While electronics and batteries are the primary focus, these sheets also find use in aerospace for lightweight shielding and in medical devices for their biocompatibility, proving their versatility across industries.

| Titanium (Ti) | Aluminum (Al) | Vanadium (V) | Tin (Sn) | |

| Ti-6Al-4V | Rest | 5.5%-6.8% | 3.5%-4.5% | |

| Ti-5Al-2.5Sn | Rest | 4.5%-5.5% | 2.0%-3.0% |

Physical Properties

| Density | 4.4-4.5g/cm³ |

| Melting Point | 1660°C |

| Coefficient of Thermal Expansion | 8-10×10⁻⁶/K (20°C-500°C) |

| Thermal Conductivity | 6-22 W/(m·K) (depending on alloy grade) |

| Electrical Resistivity | 0.14-0.17 μΩ·m |

| Tensile Strength | 600-1200 MPa (depending on alloy grade) |

| Yield Strength | 480-1100 MPa |

| Elongation at Break | 10%-25% |

| Hardness | 200-400 HB |

For more details, pls directly contact us.

The electronics and battery industries are booming, with the global battery materials market expected to grow at a CAGR of 8.3% through 2030, driven by electric vehicles (EVs), renewable energy storage, and portable electronics. Lightweight, durable, and conductive materials like our titanium foil are in high demand as manufacturers push for smaller, more efficient devices. The rise of EVs and renewable energy is fueling the need for advanced battery components, while the growth of 5G and IoT is driving demand for reliable electronics materials.

Challenges include raw material cost fluctuations and supply chain constraints, but we’ve optimized our processes to ensure steady supply and competitive pricing. Sustainability is also a big focus, with manufacturers seeking recyclable materials to meet environmental regulations. Our titanium foil is fully recyclable, aligning with these green goals. The shift toward flexible electronics and miniaturization is another trend, and our ultra-thin foil is perfectly suited for these cutting-edge applications.

Industry Trends

Miniaturization: Devices are getting smaller, and our ultra-thin foil fits perfectly in compact electronics.

Sustainability: Eco-friendly materials are a must, and our recyclable foil meets industry standards.

Electric Vehicles: The EV boom demands lightweight, conductive battery materials—our foil delivers.

Flexible Electronics: Wearables and foldable screens need flexible, durable materials like our foil.

5G and IoT: High-performance electronics for connectivity rely on reliable materials like ours.

Advanced Manufacturing: Precision processes like laser cutting and microfabrication pair well with our foil’s consistency.

Parameter | Our Thin Titanium Foil Sheets | Other Titanium Foils |

|---|---|---|

Thickness Range | 0.01 mm - 0.25 mm | 0.05 mm - 0.3 mm |

Tensile Strength | ~345 MPa | ~300-400 MPa |

Corrosion Resistance | Excellent (moisture, acids) | Good to Excellent |

Thermal Stability | Up to 400°C | Up to 350-400°C |

Surface Finish | Smooth, uniform | Varies, less consistent |

Standards Compliance | ASTM B265 | ASTM B265 or lower |

Conductivity | High for electronics | Moderate to High |

Recyclability | Fully recyclable | Varies |

Company Comparison

Our thin titanium foil sheets stand out in the market for their precision and quality. While other suppliers offer titanium foil, we go above and beyond with our advanced cold-rolling process, delivering a smoother surface and tighter tolerances for flawless performance in electronics and batteries. Our commitment to sustainability sets us apart—our foil is fully recyclable, produced with eco-friendly methods to meet the industry’s green standards. We’ve streamlined our supply chain to ensure fast, reliable delivery, even during market disruptions. Every sheet is rigorously tested to ASTM B265 standards, guaranteeing it can handle the demands of high-tech applications.

Why Choose Our Titanium Foil Sheets?

Ultra-Thin Precision: Starting at 0.01 mm, ideal for compact electronics and batteries.

Top Quality: Meets ASTM B265 standards for reliable performance.

Eco-Friendly: Fully recyclable with sustainable production processes.

Fast Delivery: Optimized supply chain ensures timely availability.

Versatile Use: Perfect for battery electrodes, circuit shielding, and flexible electronics.

The electronics and battery industries are evolving fast, with demand for lightweight, conductive, and sustainable materials set to skyrocket. As EVs, wearables, and IoT devices grow, our thin titanium foil sheets are positioned to meet these needs. Their compatibility with advanced manufacturing techniques like microfabrication and laser cutting makes them future-proof, while their recyclability aligns with the push for greener tech. We’re continuously refining our processes to stay ahead, ensuring our customers have the materials to power tomorrow’s innovations.

Conclusion

Our thin titanium foil sheets are the perfect choice for electronics and battery components. Their lightweight, conductive, and corrosion-resistant properties make them ideal for everything from battery electrodes to flexible screens. With a focus on quality, sustainability, and reliable delivery, we’re here to support your next big project. Choose our foil for materials that keep up with the fast-paced world of tech.

For more details, pls directly contact us.

About Us:

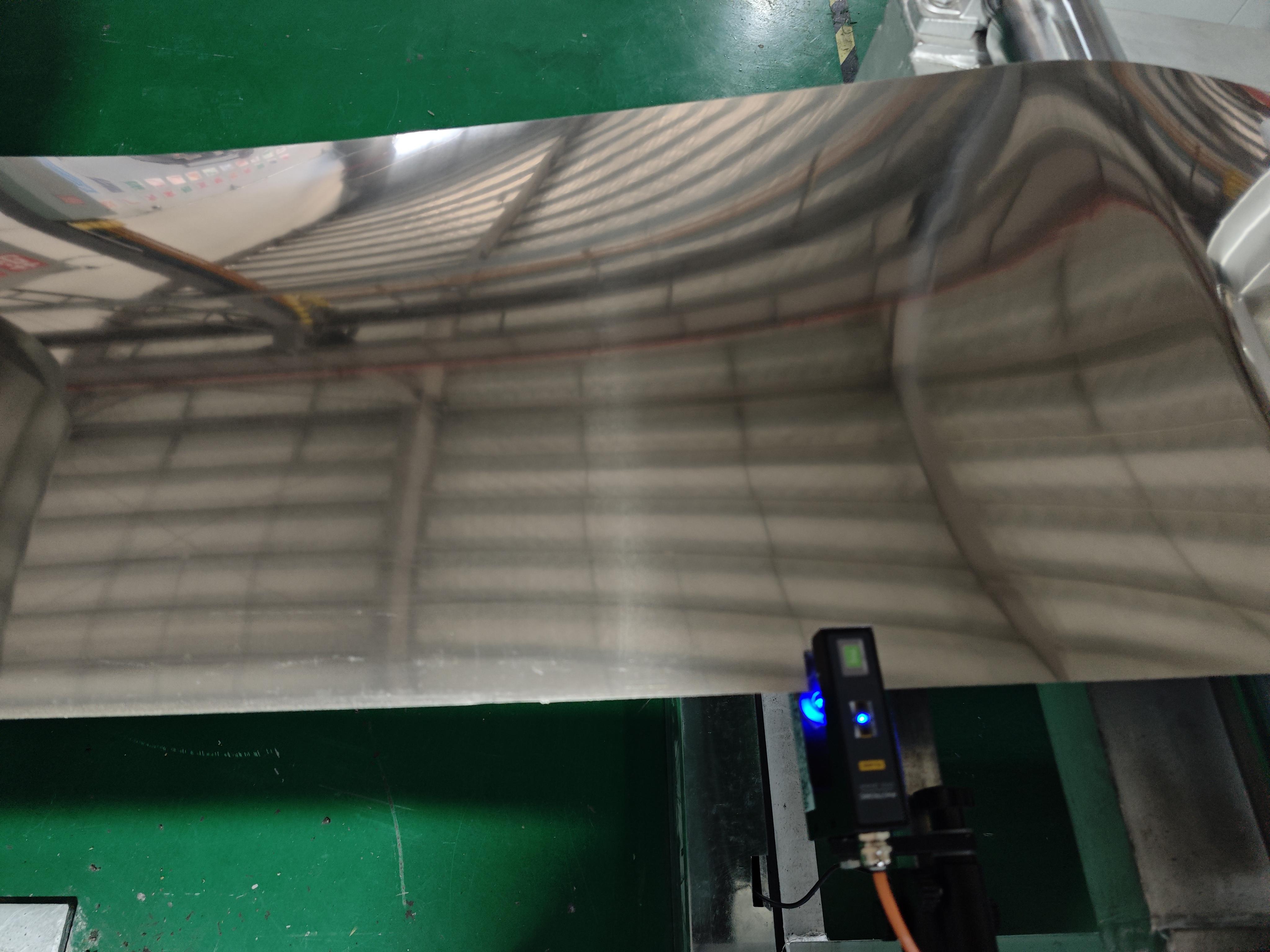

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications.

For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

FAQs:

Why is thin titanium foil ideal for electronics?

Its lightweight, conductive, and corrosion-resistant properties suit circuit boards and sensors.

How thin are these foil sheets?

They start at 0.01 mm, perfect for precision electronics and battery components.

Can they handle harsh environments?

Yes, they resist moisture, acids, and salts, ensuring durability.

Are they suitable for battery applications?

Absolutely, their conductivity and lightweight nature are ideal for electrodes.

Do they meet industry standards?

They comply with ASTM B265 for consistent quality.

Can they be used in flexible electronics?

Yes, their flexibility makes them great for wearables and foldable screens.

Are they thermally stable?

Stable up to 400°C, perfect for high-performance electronics.

Are they eco-friendly?

100% recyclable, supporting sustainable manufacturing.