Our ASTM B338 Titanium Tube s are built to tackle the toughest challenges in desalination and marine environments. These seamless and welded titanium tubes meet strict industry standards, offering unmatched corrosion resistance, strength, and durability. Whether it’s a desalination plant purifying seawater or an offshore platform battling the elements, our tubes are designed to perform where others fall short. With global demand for clean water and sustainable marine infrastructure on the rise, our titanium tubes are the backbone of reliable, long-lasting systems.

For more details, pls directly contact us.

Titanium is a superstar material, and our ASTM B338 tubes take full advantage of its properties. With a density of around 4500 kg/m³, they’re significantly lighter than stainless steel (8000 kg/m³) or copper-nickel (8900 kg/m³), making installation and handling a breeze. Their tensile strength, ranging from 900 to 1000 MPa, ensures they can withstand high pressures and stresses without buckling. But the real magic happens with their corrosion resistance. Titanium forms a natural oxide layer that shrugs off seawater, chlorides, and other corrosive agents, making it a perfect fit for harsh marine and desalination environments.

These tubes also resist biofouling, thanks to their smooth surfaces, which means less buildup of algae or marine organisms that can clog systems and reduce efficiency. They hold up at temperatures up to 400°C, ideal for thermal desalination processes like multi-stage flash (MSF) or multi-effect distillation (MED). Plus, their fatigue resistance ensures they can handle the constant vibrations and cyclic loads found in marine applications, from shipbuilding to offshore rigs.

Applications in Desalination and Marine Environments

Our ASTM B338 titanium tubes are a go-to for desalination plants, where they’re used in heat exchangers, condensers, and piping systems. Desalination processes like reverse osmosis (RO) and thermal distillation expose components to aggressive saline water and high pressures. Our tubes stand up to these conditions, reducing downtime and maintenance costs. Their long lifespan—often decades—makes them a cost-effective choice for plants aiming to maximize uptime and efficiency.

In marine environments, these tubes shine in offshore platforms, shipbuilding, and subsea equipment. They’re used in cooling systems, hydraulic lines, and structural components, where seawater corrosion is a constant threat. Their lightweight nature also helps reduce fuel consumption in marine vessels, while their strength ensures reliability in high-stress applications like deep-sea pipelines or wave energy converters.

Beyond desalination and marine, our titanium tubes find homes in other industries. In chemical processing, they handle corrosive fluids with ease. In power generation, they’re used in heat exchangers for their thermal stability. Even in aerospace, their strength-to-weight ratio makes them a favorite for hydraulic systems. But for us, desalination and marine applications are where they truly make a splash.

| Titanium (Ti) | Aluminum (Al) | Vanadium (V) | Tin (Sn) | |

| Ti-6Al-4V | Rest | 5.5%-6.8% | 3.5%-4.5% | |

| Ti-5Al-2.5Sn | Rest | 4.5%-5.5% | 2.0%-3.0% |

Physical Properties

| Density | 4.4-4.5g/cm³ |

| Melting Point | 1660°C |

| Coefficient of Thermal Expansion | 8-10×10⁻⁶/K (20°C-500°C) |

| Thermal Conductivity | 6-22 W/(m·K) (depending on alloy grade) |

| Electrical Resistivity | 0.14-0.17 μΩ·m |

| Tensile Strength | 600-1200 MPa (depending on alloy grade) |

| Yield Strength | 480-1100 MPa |

| Elongation at Break | 10%-25% |

| Hardness | 200-400 HB |

For more details, pls directly contact us.

The desalination and marine sectors are booming, and our ASTM B338 titanium tubes are riding the wave. Global water scarcity is driving massive investments in desalination, with the market expected to grow from $15.9 billion in 2023 to $28.9 billion by 2030, at a CAGR of 8.9%. Titanium’s corrosion resistance and durability make it a top choice for plants aiming to meet rising demand for clean water, especially in regions like the Middle East and North Africa.

Marine industries are also evolving. Offshore wind farms, wave energy projects, and deep-sea exploration are pushing the need for materials that can survive harsh saltwater environments. Titanium’s ability to resist corrosion and fatigue makes it a standout for these applications. Add to that the rise of sustainable practices—titanium’s recyclability and long lifespan align perfectly with the industry’s push for eco-friendly solutions.

Advances in manufacturing, like seamless tube production and additive manufacturing, are making titanium more cost-effective. These innovations let us produce complex designs with less waste, lowering costs while maintaining quality. As regulations tighten on emissions and environmental impact, our lightweight tubes help marine vessels cut fuel use, supporting greener operations.

How We Stand Out

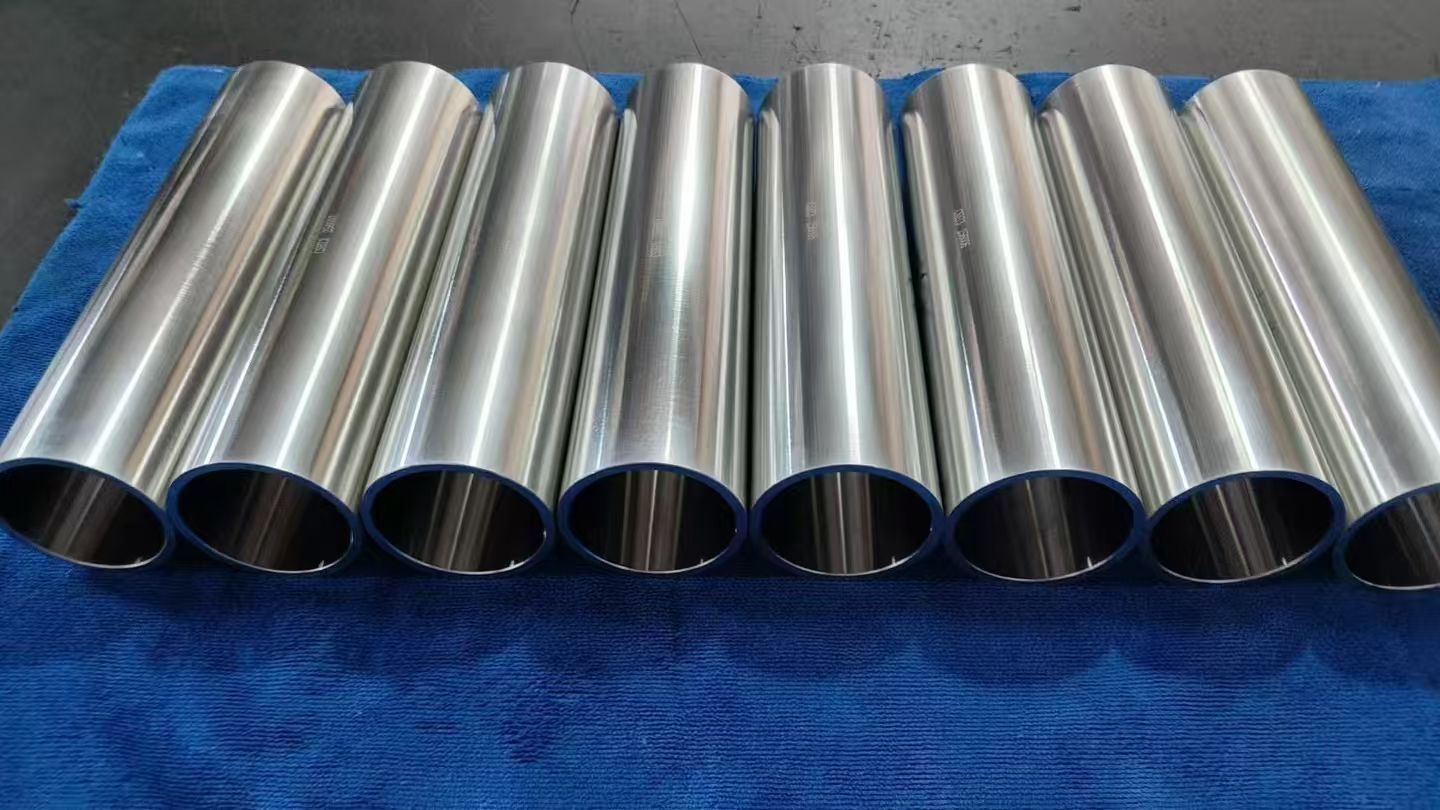

Our ASTM B338 titanium tubes aren’t just another product—they’re a testament to our commitment to quality and innovation. We manufacture to exacting standards, ensuring every tube meets ASTM B338 specifications for seamless and welded titanium. Our advanced production techniques, like precision forging and cold drawing, deliver tubes with superior dimensional accuracy and surface finish. This means better performance, less fouling, and easier integration into your systems.

We’re also big on customization. Need a specific diameter, wall thickness, or alloy grade like Ti-6Al-4V or Grade 2? We’ve got you covered. Our heat treatment processes, like annealing or stress relieving, optimize the tubes’ mechanical properties for your specific application. And our supply chain is rock-solid, with access to high-purity titanium sponge and rigorous quality checks to ensure consistency.

Compared to a typical competitor, our tubes offer tighter tolerances and better fatigue resistance, thanks to our proprietary manufacturing methods. We also prioritize sustainability, using energy-efficient processes and recycling titanium scrap to minimize waste. Our lead times are faster, and our technical support team works with you from design to delivery, ensuring you get exactly what you need. Whether it’s a small batch for a prototype or a large order for a desalination plant, we deliver on time and on spec.

Comparison Table: ASTM B338 Titanium vs. Stainless Steel vs. Copper-Nickel for Desalination and Marine Applications

|

Parameter |

ASTM B338 Titanium |

Stainless Steel |

Copper-Nickel |

|---|---|---|---|

|

Density (kg/m³) |

~4500 (Low) |

~8000 (High) |

~8900 (High) |

|

Tensile Strength (MPa) |

~900–1000 (High) |

~520–690 (Moderate) |

~310–410 (Low) |

|

Corrosion Resistance |

Excellent (Resists seawater, chlorides) |

Good (Prone to pitting in saline environments) |

Good (Moderate resistance to seawater) |

|

Thermal Conductivity (W/m·K) |

~15–22 (Low, retains heat) |

~15–25 (Moderate) |

~30–50 (High, dissipates heat) |

|

Max Service Temperature (°C) |

~400 (High) |

~800 (Very High) |

~300 (Moderate) |

|

Biofouling Resistance |

High (Smooth surface reduces buildup) |

Moderate (Prone to fouling) |

Moderate (Susceptible to biofouling) |

|

Fatigue Resistance |

Excellent (Handles cyclic loads well) |

Good (Moderate under stress) |

Moderate (Prone to fatigue in dynamic loads) |

|

Cost |

Higher (Premium material) |

Moderate (Widely available) |

Moderate (Less costly but shorter lifespan) |

Titanium’s not cheap, and its low thermal conductivity can make machining a bit tricky. But we’ve tackled these challenges head-on. Our advanced manufacturing techniques, like automated welding and 3D printing, help keep costs down without compromising quality. We use specialized tooling to handle titanium’s unique properties, ensuring smooth production and consistent results. For customers worried about budget, we work closely to optimize designs—think thinner walls or shorter lengths—to reduce material use while maintaining performance.

The Future of ASTM B338 Titanium Tubes

The future looks bright for titanium in desalination and marine applications. As global demand for clean water grows, desalination plants will need reliable, long-lasting materials to keep up. Our tubes are ready to meet that demand, offering unmatched durability and efficiency. In marine environments, the rise of offshore renewable energy and deep-sea exploration will only increase the need for corrosion-resistant materials like titanium.

We’re also excited about new manufacturing technologies. Additive manufacturing is opening up possibilities for complex, lightweight designs that were once too expensive or difficult to produce. Sustainability will continue to shape the industry, and our eco-friendly production processes—combined with titanium’s recyclability—position us as a leader in green innovation.

Why Choose Our ASTM B338 Titanium Tubes?

Our ASTM B338 titanium tubes are built to last, delivering top performance in the harshest desalination and marine environments. They’re lightweight, strong, and corrosion-resistant, making them the perfect choice for everything from desalination heat exchangers to offshore pipelines. With our cutting-edge manufacturing, flexible customization, and unwavering focus on quality, we’re not just selling tubes—we’re helping you build systems that stand the test of time.

Ready to take your desalination or marine project to the next level? Our team is here to provide the perfect titanium tube solution, tailored to your needs. Let’s make your next project a success with the power of ASTM B338 titanium.

For more details, pls directly contact us.

About Us:

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications.

For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

FAQs:

-

What makes ASTM B338 titanium tubes ideal for desalination?

Their exceptional corrosion resistance and high strength make them perfect for handling saline water and harsh desalination processes. -

Why use titanium tubes in marine environments?

They resist corrosion from seawater, withstand high pressures, and maintain durability in extreme marine conditions. -

How do ASTM B338 titanium tubes improve desalination efficiency?

Their smooth surfaces reduce fouling, and their durability minimizes maintenance, boosting system efficiency. -

Are ASTM B338 titanium tubes suitable for high-pressure marine applications?

Yes, their high strength-to-weight ratio ensures they handle extreme pressures without deforming. -

What’s the lifespan of titanium tubes in desalination plants?

They can last decades with minimal degradation, even in constant exposure to corrosive saltwater. -

Can ASTM B338 titanium tubes be customized for specific projects?

Absolutely, we offer tailored sizes, wall thicknesses, and finishes to meet unique project needs. -

How do titanium tubes perform in high-temperature desalination processes?

They maintain structural integrity at elevated temperatures, ensuring reliable performance in thermal desalination systems. -

What industry trends support titanium tubes in marine and desalination applications?

Growing demand for sustainable water solutions and offshore infrastructure drives the adoption of durable, corrosion-resistant materials.