We’re proud to offer our high-performance Ti-6Al-4V alloy tube, a game-changer for automotive exhaust systems. Known as Grade 5 titanium, this alpha-beta alloy is the go-to choice for industries chasing strength, durability, and lightweight performance. With a composition of 6% aluminum, 4% vanadium, and the rest titanium, it’s engineered to deliver top-tier results in the toughest conditions. Whether you’re building a high-performance race car or designing a fuel-efficient everyday vehicle, our Ti-6Al-4V tubes are built to elevate your exhaust systems to the next level.

For more details, pls directly contact us.

Ti-6Al-4V is no ordinary material. It’s a titanium alloy celebrated for its killer combo of high strength, low weight, and unreal corrosion resistance. With a density of about 4420 kg/m³, it’s much lighter than stainless steel (around 8000 kg/m³), making it a dream for automotive engineers looking to shave off weight without sacrificing durability. Its tensile strength clocks in at around 1000 MPa, blowing past aluminum’s 310 MPa and even outpacing many stainless steel grades. Plus, it can handle temperatures up to 400°C without breaking a sweat, which is perfect for the scorching environment of exhaust systems.

What really sets it apart is its corrosion resistance. Exhaust systems deal with harsh gases and moisture, but Ti-6Al-4V forms a protective oxide layer that laughs off corrosion, even in salty or acidic conditions. This means longer-lasting parts and fewer replacements, saving time and money in the long run. Its fatigue resistance is another big win—cyclic loads from engine vibrations? No problem. This alloy keeps going strong, making it a favorite for high-performance vehicles where reliability is non-negotiable.

Why Use Ti-6Al-4V in Automotive Exhaust Systems?

Exhaust systems are the unsung heroes of any vehicle, channeling hot gases while keeping performance and efficiency in check. Our Ti-6Al-4V alloy tubes shine here for a few key reasons:

Lightweight Performance: Reducing vehicle weight is a big deal for fuel efficiency and speed. Our tubes cut down on mass compared to traditional stainless steel, giving you better gas mileage and sharper handling, especially in performance cars.

Heat Resistance: Exhaust systems run hot—really hot. Ti-6Al-4V stays stable at high temperatures, ensuring your exhaust components don’t warp or degrade under pressure.

Corrosion Resistance: From road salt to acidic exhaust gases, our tubes hold up in environments that would eat away at lesser materials. This durability translates to longer service life and lower maintenance costs.

Customizability: We offer Ti-6Al-4V tubes in various sizes, shapes, and finishes, so you can get exactly what your design needs, whether it’s for a sleek sports car or a rugged off-road beast.

| Titanium (Ti) | Aluminum (Al) | Vanadium (V) | Tin (Sn) | |

| Ti-6Al-4V | Rest | 5.5%-6.8% | 3.5%-4.5% | |

| Ti-5Al-2.5Sn | Rest | 4.5%-5.5% | 2.0%-3.0% |

Physical Properties

| Density | 4.4-4.5g/cm³ |

| Melting Point | 1660°C |

| Coefficient of Thermal Expansion | 8-10×10⁻⁶/K (20°C-500°C) |

| Thermal Conductivity | 6-22 W/(m·K) (depending on alloy grade) |

| Electrical Resistivity | 0.14-0.17 μΩ·m |

| Tensile Strength | 600-1200 MPa (depending on alloy grade) |

| Yield Strength | 480-1100 MPa |

| Elongation at Break | 10%-25% |

| Hardness | 200-400 HB |

For more details, pls directly contact us.

The automotive industry is in the middle of a massive shift, and Ti-6Al-4V is right at the heart of it. With global demand for lightweight, eco-friendly vehicles on the rise, this alloy is becoming a must-have. The push for better fuel efficiency and lower emissions is huge, especially with stricter regulations popping up worldwide. Our Ti-6Al-4V tubes help automakers meet these standards by cutting weight without compromising strength.

Additive manufacturing (3D printing) is another game-changer. It’s making Ti-6Al-4V more accessible by allowing complex, custom exhaust components to be produced with less waste and lower costs. The rise of electric vehicles (EVs) is also shaking things up. While EVs don’t have traditional exhaust systems, hybrid and performance vehicles still rely on them, and Ti-6Al-4V is perfect for keeping weight down in these applications.

Motorsports is another big driver. High-performance cars need materials that can handle extreme conditions, and our alloy delivers. From Formula 1 to rally racing, Ti-6Al-4V is the go-to for exhaust systems that need to be light, strong, and durable. The global Ti-6Al-4V market is growing fast—valued at $8.1 billion in 2023 and expected to hit $13.53 billion by 2030, with a CAGR of 7.61%. Automotive is a key player in this growth, alongside aerospace and medical applications.

Applications Beyond Exhaust Systems

While we’re all about automotive exhaust systems, Ti-6Al-4V’s versatility stretches far and wide. In aerospace, it’s used in everything from airframes to turbine blades thanks to its strength-to-weight ratio. In the medical world, its biocompatibility makes it a star in implants and surgical tools. Marine applications? You bet—its corrosion resistance is a lifesaver in saltwater environments. Even in sports equipment, like high-end bicycle frames and golf clubs, Ti-6Al-4V is a top pick for its lightweight durability.

For automotive, it’s not just exhausts. Our alloy is used in engine valves, suspension components, and connecting rods, especially in high-performance and luxury vehicles. These applications demand materials that can take a beating while keeping weight low, and Ti-6Al-4V delivers every time.

Comparison Table: Ti-6Al-4V vs. Stainless Steel vs. Aluminum for Exhaust Systems

Parameter | Ti-6Al-4V Alloy | Stainless Steel | Aluminum |

|---|---|---|---|

Density (kg/m³) | ~4420 (Low) | ~8000 (High) | ~2700 (Very Low) |

Tensile Strength (MPa) | ~1000 (High) | ~570 (Moderate) | ~310 (Low) |

Corrosion Resistance | Excellent (Resists saltwater, exhaust gases) | Good (Prone to rust in extreme conditions) | Moderate (Susceptible to corrosion) |

Thermal Conductivity (W/m·K) | ~6.7–7.5 (Low, retains heat) | ~15–25 (Moderate) | ~200 (High, dissipates heat quickly) |

Max Service Temperature (°C) | ~400 (High) | ~800 (Very High) | ~200 (Low) |

Weight Reduction | High (Improves fuel efficiency) | Low (Heavier, less efficient) | High (Light but less durable) |

Fatigue Resistance | Excellent (Handles cyclic loads well) | Good (Moderate under high stress) | Poor (Prone to fatigue cracking) |

Cost | Higher (Premium material) | Moderate (Widely available) | Low (Cost-effective but less robust) |

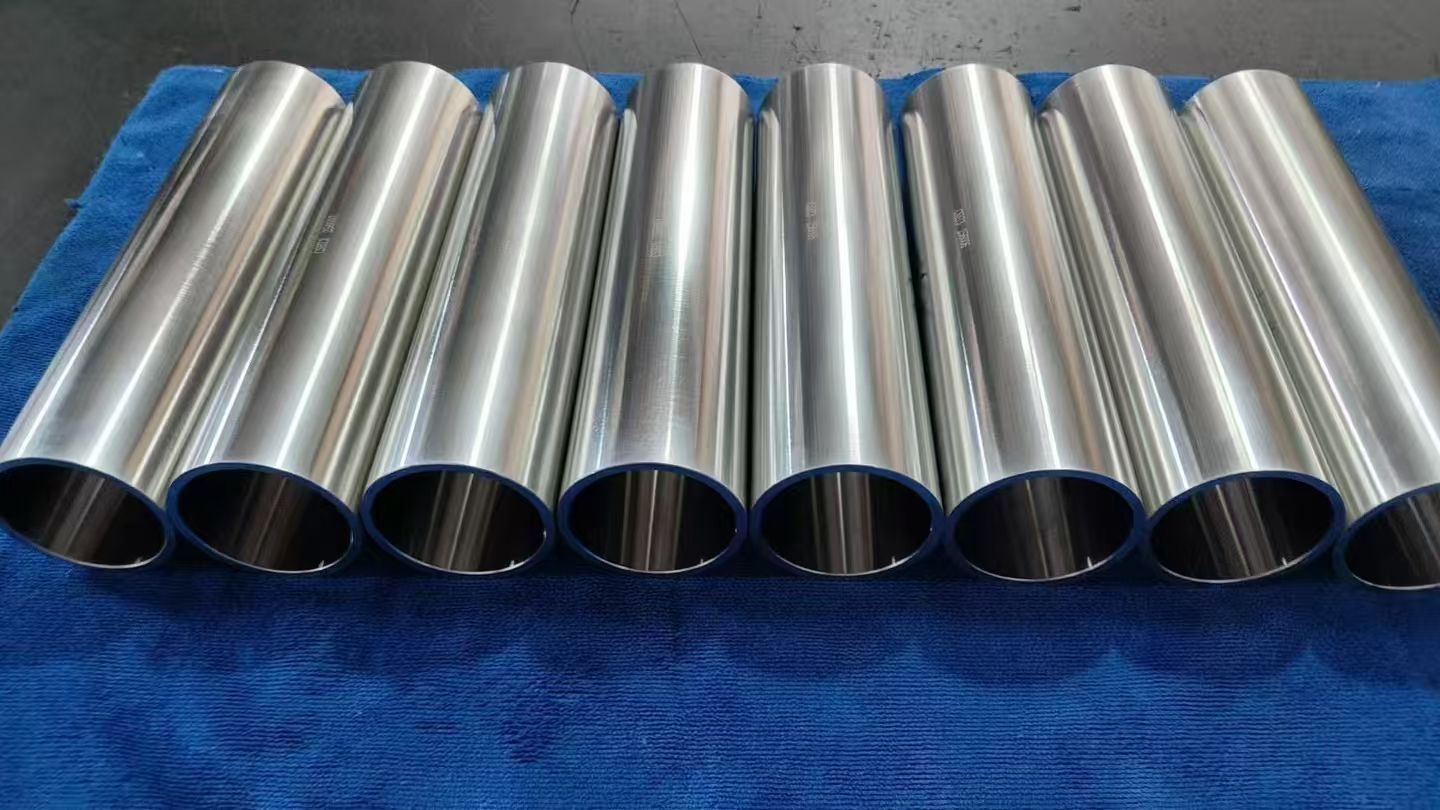

Our company’s Ti-6Al-4V alloy tubes are a cut above the rest, and here’s why. We focus on precision manufacturing, ensuring every tube meets strict quality standards like ASTM B338 and B337. Our tubes are crafted with advanced techniques, including seamless welding and custom heat treatments, to dial in the exact microstructure and mechanical properties you need. Whether it’s mill annealing for balanced strength or solution treating for extra toughness, we’ve got the expertise to deliver.

We also prioritize sustainability. Our production processes minimize waste, and we’re investing in cutting-edge additive manufacturing to make complex designs more cost-effective. Plus, our supply chain is rock-solid, with access to high-quality titanium sponge and rigorous quality control to ensure consistency. Unlike others, we offer end-to-end support—from design consultation to delivery—making sure you get the perfect product for your project.

Compared to a typical competitor, our tubes offer superior fatigue resistance and tighter tolerances, thanks to our proprietary processing methods. We also provide faster lead times and more flexible customization options, so you’re not stuck waiting or compromising on your vision. Our commitment to innovation means we’re always pushing the envelope, whether it’s through new heat treatment techniques or advanced surface finishes to boost performance.

Challenges and Solutions

Ti-6Al-4V isn’t perfect—it’s pricier than stainless steel or aluminum, and its low thermal conductivity can make machining tricky. But we’ve got solutions. Our advanced manufacturing techniques, like precision forging and 3D printing, help keep costs down while maintaining quality. We also use specialized tooling to overcome machinability issues, ensuring smooth production and consistent results. For customers worried about cost, we offer tailored solutions to balance performance and budget, like optimizing tube dimensions to reduce material use without sacrificing strength.

The Future of Ti-6Al-4V in Automotive

Looking ahead, Ti-6Al-4V is set to play an even bigger role in automotive. As EVs and hybrids dominate the market, lightweight materials will be critical for maximizing range and performance. Our alloy is perfectly positioned to meet this demand, especially in high-performance hybrids where exhaust systems still play a role. Advances in additive manufacturing will also make it easier to produce complex, lightweight exhaust components, driving down costs and opening up new design possibilities.

Sustainability is another big focus. We’re committed to eco-friendly production, from recycling titanium scrap to reducing energy use in manufacturing. As the industry moves toward greener practices, our Ti-6Al-4V tubes will help automakers meet environmental goals while delivering top-notch performance.

Why Choose Us?

Our Ti-6Al-4V alloy tubes are built for the future of automotive. They’re lightweight, strong, and ready to handle the toughest conditions, from racetracks to daily commutes. With our expertise, cutting-edge manufacturing, and customer-first approach, we’re not just selling tubes—we’re helping you build better vehicles. Whether you’re chasing speed, efficiency, or durability, our Ti-6Al-4V tubes are the way to go.

Ready to level up your exhaust systems? Our team is here to help you find the perfect solution, customized to your needs. Let’s make your next project a winner with the power of Ti-6Al-4V.

For more details, pls directly contact us.

About Us:

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications.

For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

FAQs:

What is Ti-6Al-4V alloy used for in automotive exhaust systems?

It’s used for exhaust pipes and components due to its high strength, low weight, and excellent corrosion resistance, improving performance and durability.Why choose Ti-6Al-4V over stainless steel for exhaust systems?

It offers a better strength-to-weight ratio, resists corrosion in harsh environments, and handles high temperatures without deforming.How does Ti-6Al-4V improve fuel efficiency?

Its lightweight nature reduces vehicle weight, leading to better fuel economy and lower emissions.Is Ti-6Al-4V suitable for high-performance vehicles?

Absolutely, its high strength and heat resistance make it ideal for motorsports and luxury cars needing top performance.What’s the durability of Ti-6Al-4V in exhaust applications?

It withstands extreme temperatures and corrosive exhaust gases, ensuring long-lasting performance with minimal wear.Can Ti-6Al-4V tubes be customized for specific exhaust designs?

Yes, they can be tailored in size, shape, and finish to meet specific vehicle requirements.How does Ti-6Al-4V handle high-temperature environments?

It maintains structural integrity at temperatures up to 400°C, perfect for hot exhaust systems.What industry trends support the use of Ti-6Al-4V in automotive applications?

Growing demand for lightweight, durable materials in electric and high-performance vehicles drives its adoption.