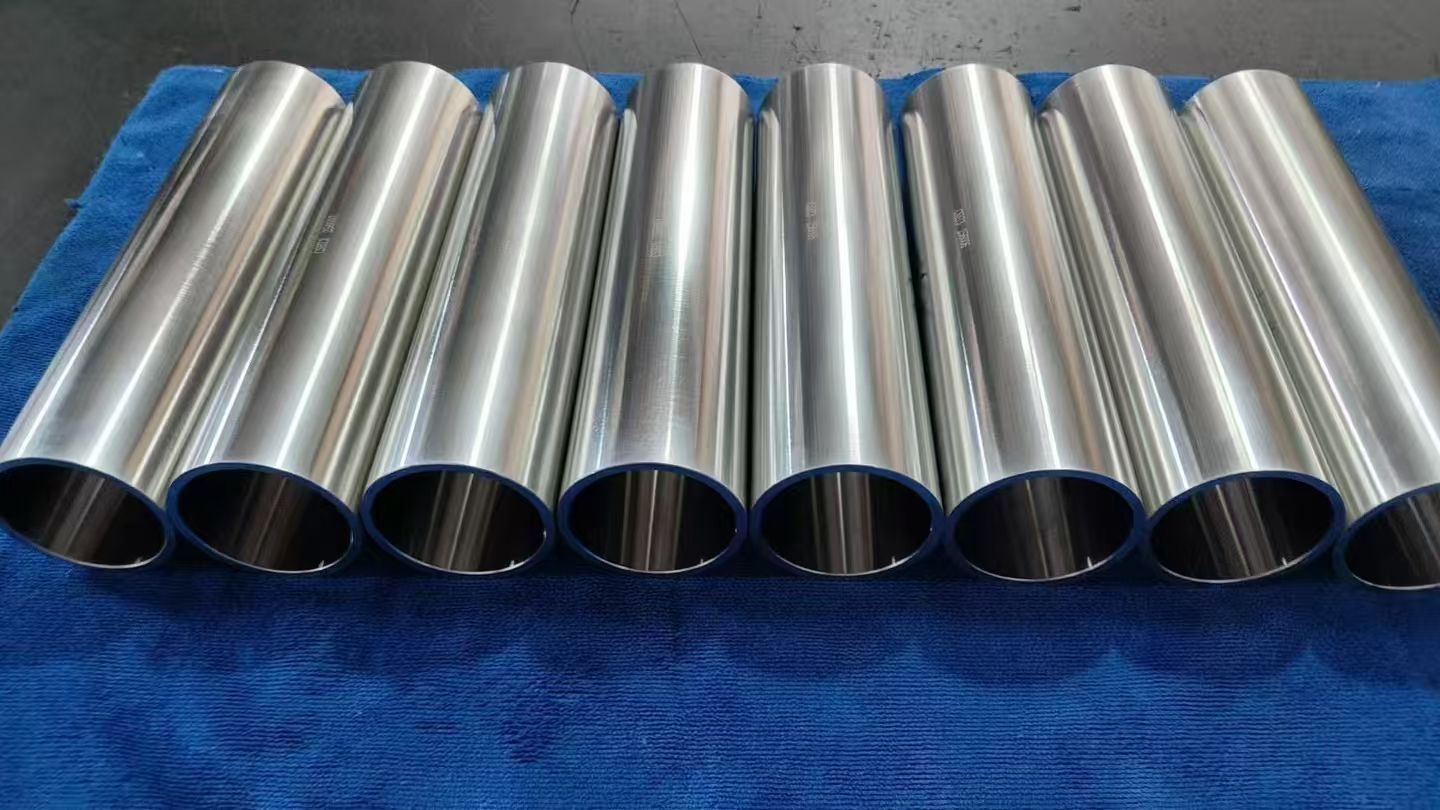

Our titanium welded tubes are built to tackle the toughest conditions in chemical processing plants. Crafted from high-quality titanium, typically Grade 2, 7, or 12, these tubes are all about durability, corrosion resistance, and cost-efficiency. They’re lightweight—40% lighter than stainless steel—and pack a tensile strength of 345-450 MPa for Grade 2, making them perfect for handling aggressive chemicals without breaking a sweat.

Unlike seamless tubes, our welded tubes are made by rolling and welding titanium sheets, offering a budget-friendly option for larger diameters without sacrificing performance. They meet strict ASTM B338 and ASME SB338 standards, ensuring top-notch quality for chemical applications. Whether you need piping for acids, heat exchanger tubes, or reactor components, we can customize sizes, wall thicknesses, and finishes to fit your plant’s exact needs. Our titanium welded tubes are designed to keep your operations running smoothly, no matter how harsh the environment.

For more details, pls directly contact us.

Titanium welded tubes are a game-changer for chemical processing because they’re practically bulletproof against corrosion. Acids, chlorides, and caustic solutions? These tubes shrug them off thanks to a natural oxide layer that protects against rust and degradation. This makes them ideal for environments where other materials, like stainless steel, might falter.

They’re also lightweight, which simplifies installation and reduces structural load in chemical plants. Despite being welded, they maintain excellent strength and durability, handling high-pressure systems with ease. Plus, their weldability makes them versatile for complex piping designs. From low maintenance to long lifespan, our titanium welded tubes are built to keep your plant humming along without costly downtime.

Industry Analysis

The chemical processing industry is growing steadily, with a projected CAGR of 5.5% through 2030, driven by demand for specialty chemicals, pharmaceuticals, and sustainable processes. Titanium is becoming a go-to material due to its ability to withstand corrosive substances and extreme conditions. As plants handle increasingly aggressive chemicals, the need for reliable, long-lasting materials like our titanium welded tubes is skyrocketing.

Trends like green chemistry and energy-efficient processing are shaping the industry, pushing for materials that reduce maintenance and environmental impact. Titanium fits the bill perfectly, offering durability that cuts down on replacements and waste. Meanwhile, advancements in welding technology are making titanium tubes more affordable, expanding their use in everything from petrochemicals to fertilizers.

Challenges like high material costs and complex fabrication persist, but we address these by streamlining production and offering cost-effective welded tubes. The industry’s future is bright, with titanium playing a key role in supporting safer, more efficient chemical processing.

| Titanium (Ti) | Aluminum (Al) | Vanadium (V) | Tin (Sn) | |

| Ti-6Al-4V | Rest | 5.5%-6.8% | 3.5%-4.5% | |

| Ti-5Al-2.5Sn | Rest | 4.5%-5.5% | 2.0%-3.0% |

Physical Properties

| Density | 4.4-4.5g/cm³ |

| Melting Point | 1660°C |

| Coefficient of Thermal Expansion | 8-10×10⁻⁶/K (20°C-500°C) |

| Thermal Conductivity | 6-22 W/(m·K) (depending on alloy grade) |

| Electrical Resistivity | 0.14-0.17 μΩ·m |

| Tensile Strength | 600-1200 MPa (depending on alloy grade) |

| Yield Strength | 480-1100 MPa |

| Elongation at Break | 10%-25% |

| Hardness | 200-400 HB |

For more details, pls directly contact us.

Our titanium welded tubes excel in a variety of chemical processing applications:

-

Heat Exchangers: Their corrosion resistance and thermal conductivity make them ideal for transferring heat in acidic or chloride-rich environments.

-

Piping Systems: Perfect for transporting corrosive fluids like sulfuric acid or brine without degrading.

-

Reactors: Used in reactor vessels for their ability to withstand high temperatures and aggressive chemicals.

-

Condensers: Their durability ensures reliable performance in condensing systems exposed to harsh conditions.

-

Storage Tanks: Integrated into tank piping for safe handling of volatile or corrosive substances.

These applications show why titanium welded tubes are a staple in chemical plants—they’re tough, reliable, and built to handle the harshest processes.

Company Comparison

In the world of titanium welded tubes, we stand out by focusing on quality, flexibility, and value. Many in the industry churn out generic products with limited customization, but we take a different approach. Our tubes are crafted with precision welding techniques, meeting ASTM and ASME standards through rigorous quality checks. We don’t just deliver tubes; we tailor them to your plant’s needs, offering custom sizes, thicknesses, and finishes for seamless integration.

Our welded tubes balance performance and affordability, making them a smart choice for large-diameter applications where seamless tubes might be overkill. While others might compromise on quality to cut costs, we use advanced manufacturing to keep prices competitive without sacrificing durability. Our expertise in titanium welding ensures strong, leak-free joints that stand up to the toughest chemical environments.

We also go the extra mile with customer support. From design consultation to delivery, we’re with you every step, ensuring your project runs smoothly. Others might supply materials, but we provide solutions that keep your chemical plant running at peak performance.

Comparison Table: Titanium Welded Tube vs. Other Materials

|

Parameter |

Titanium Welded Tube |

Stainless Steel |

PVC |

|---|---|---|---|

|

Density (g/cm³) |

4.51 (Lightweight) |

7.9 (Heavy) |

1.4 (Very Lightweight) |

|

Tensile Strength (MPa) |

345-450 (Grade 2) |

500-700 (Varies by alloy) |

40-60 |

|

Corrosion Resistance |

Excellent (Acids, chlorides) |

Good (Prone to pitting) |

Good (Limited to chemicals) |

|

Temperature Range (°C) |

-253 to 400 |

-50 to 800 |

0 to 60 |

|

Fatigue Resistance |

Moderate to High |

High |

Low |

|

Cost |

Moderate to High |

Moderate |

Low |

|

Weight Savings |

40% lighter than steel |

Heavy |

Lighter than titanium |

|

Applications |

Chemical, marine, medical |

Chemical, industrial |

Chemical, water systems |

What sets our titanium welded tubes apart? It’s our commitment to excellence and innovation. We use state-of-the-art welding and testing to ensure every tube is flawless, with strong welds and consistent corrosion resistance. Our customization options are unmatched—whether you need specific diameters for a heat exchanger or unique finishes for a reactor, we make it happen.

Sustainability is a big part of our story. We optimize production to minimize waste and energy use, aligning with the chemical industry’s push for greener practices. Our streamlined supply chain ensures fast delivery, keeping your project on track. And by leveraging cutting-edge welding technology, we keep costs down, making high-performance titanium accessible for your budget.

Looking Ahead

The chemical processing industry is evolving, with demands for durability, efficiency, and sustainability at an all-time high. Our titanium welded tubes are ready to meet those challenges, whether it’s for next-gen petrochemical plants, pharmaceutical production, or eco-friendly processes. We’re constantly innovating, exploring new ways to enhance our tubes and support your projects.

Choose our titanium welded tubes for your chemical processing needs, and you’re choosing reliability, performance, and a partner dedicated to your success. Let’s tackle the toughest chemical challenges together—one durable tube at a time.

For more details, pls directly contact us.

About Us:

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications.

For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

FAQs:

-

What makes titanium welded tubes suitable for chemical processing plants?

Titanium welded tubes offer excellent corrosion resistance, high strength, and durability, ideal for handling aggressive chemicals and high-pressure systems in chemical plants. -

Which titanium grades are commonly used for welded tubes in chemical processing?

Grades 2, 7, and 12 are popular due to their corrosion resistance and ability to withstand harsh chemical environments. -

How do titanium welded tubes resist corrosion in chemical plants?

They form a protective oxide layer that resists corrosion from acids, chlorides, and other aggressive chemicals, ensuring long-term reliability. -

What applications in chemical processing use titanium welded tubes?

They’re used in heat exchangers, piping systems, reactors, and condensers for their durability and resistance to corrosive fluids. -

How do titanium welded tubes compare to seamless tubes?

Welded tubes are more cost-effective for larger diameters, offering similar corrosion resistance but slightly lower strength compared to seamless tubes. -

Are titanium welded tubes compliant with industry standards?

Yes, they meet ASTM B338, ASME SB338, and other chemical industry standards, ensuring quality and performance. -

Can titanium welded tubes be customized for specific chemical plant needs?

Absolutely, we provide custom sizes, wall thicknesses, and finishes to match precise requirements for chemical processing systems. -

Are titanium welded tubes cost-effective for chemical processing?

Their upfront cost is higher, but their long lifespan and low maintenance needs make them a cost-saving choice over time.