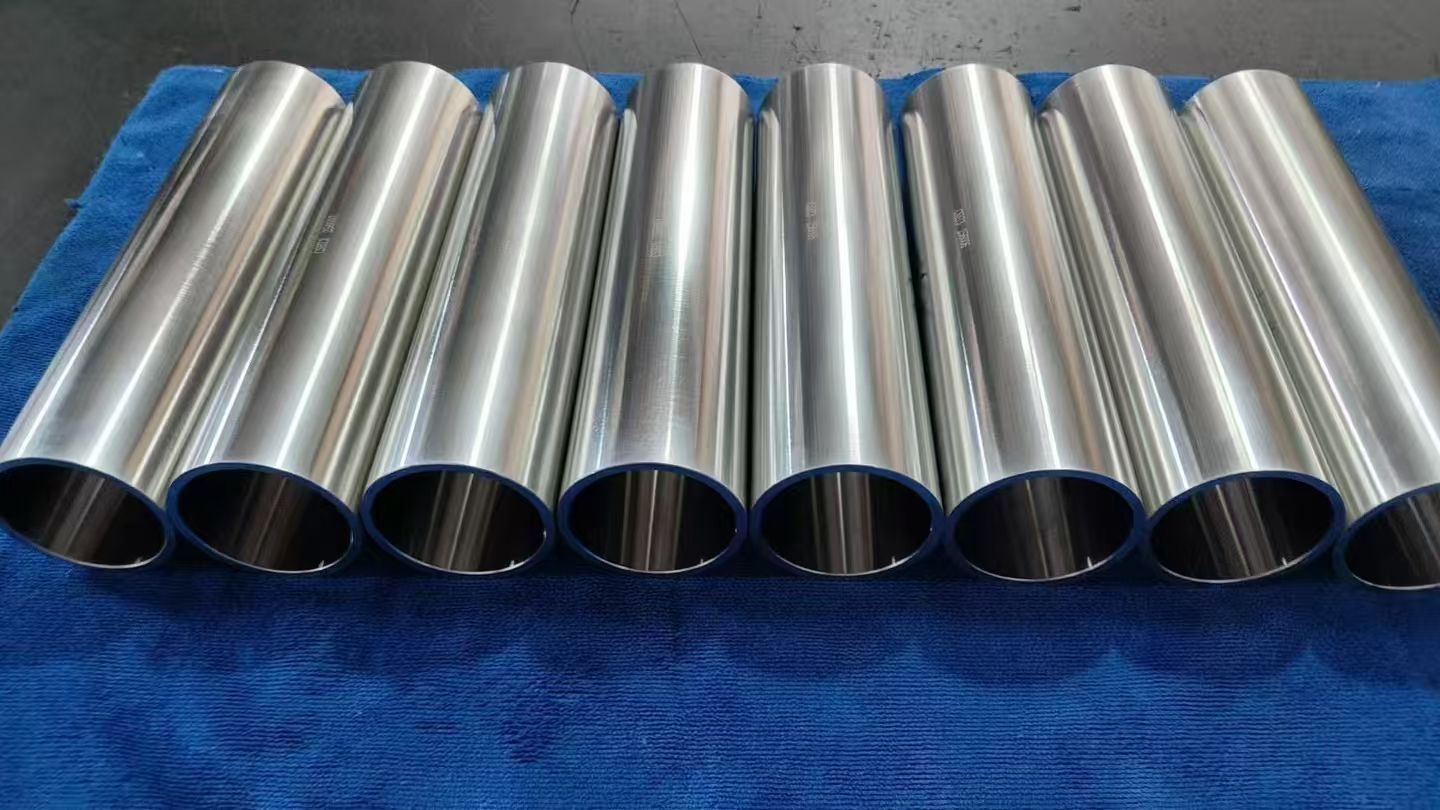

Our Grade 9 Titanium Tube s, made from the Ti-3Al-2.5V alloy, are a top choice for medical implants. These tubes pack a punch with high strength, light weight, and unbeatable biocompatibility. Weighing 40% less than stainless steel and boasting a tensile strength of 860-900 MPa, they’re perfect for demanding medical applications. Their ability to resist corrosion in body fluids and integrate seamlessly with human tissue makes them a go-to for implants that need to last.

We craft these tubes using seamless processes like extrusion, ensuring a smooth, uniform structure that’s critical for precision medical devices. They meet strict standards like ASTM F136 and ISO 5832-11, so you can trust their safety and quality. Whether you need tiny tubes for cardiovascular stents or larger ones for orthopedic implants, we customize sizes, wall thicknesses, and finishes to fit your exact specs. Our Grade 9 titanium tubes are built to perform, helping patients live better, longer lives.

For more details, pls directly contact us.

Grade 9 titanium is a standout for medical implants because it’s as biocompatible as it gets. It’s non-toxic, doesn’t cause allergic reactions, and bonds well with bone and tissue, making it ideal for long-term implants like hip replacements or dental screws. Its corrosion resistance is a big deal—body fluids like blood and saline won’t degrade these tubes, ensuring they stay strong for years.

These tubes are also lightweight, which reduces stress on the body and improves patient comfort. With excellent fatigue resistance, they handle the repetitive stresses of daily movement without cracking or failing. Plus, they’re easy to form and weld, giving medical device manufacturers flexibility to create complex designs. For surgeons and patients alike, our Grade 9 titanium tubes deliver reliability and performance you can count on.

Industry Analysis

The medical implant industry is booming, with a projected CAGR of 7.2% through 2030, driven by an aging population, rising chronic diseases, and advances in medical technology. Titanium alloys like Grade 9 are at the heart of this growth, thanks to their biocompatibility and durability. Demand for orthopedic implants, dental implants, and cardiovascular devices is surging, especially in minimally invasive surgeries where precision materials make all the difference.

Trends like 3D printing and personalized implants are reshaping the industry, allowing for custom designs that fit patients perfectly. Lightweight materials are also in high demand to improve patient outcomes and reduce recovery times. However, challenges like high material costs and stringent regulatory requirements persist. We tackle these head-on by optimizing our manufacturing processes to keep costs competitive while meeting the toughest standards.

The future looks bright, with innovations in biocompatible coatings and smart implants pushing the boundaries of what’s possible. Our Grade 9 titanium tubes are ready to meet these evolving needs, supporting the next wave of medical breakthroughs.

Applications in Medical Implants

Our Grade 9 titanium seamless tubes shine in a variety of medical applications:

-

Orthopedic Implants: Used in bone screws, plates, and joint replacements for their strength and bone-bonding properties.

-

Dental Implants: Perfect for dental posts and abutments, offering durability and biocompatibility.

-

Spinal Fusion Devices: Their fatigue resistance makes them ideal for rods and cages in spinal surgeries.

-

Cardiovascular Stents: Small-diameter tubes provide flexibility and corrosion resistance for heart stents.

-

Surgical Instruments: Lightweight and strong, they’re used in precision tools for minimally invasive procedures.

These applications highlight why Grade 9 titanium is a medical industry favorite—it’s versatile, safe, and built to last inside the human body.

| Titanium (Ti) | Aluminum (Al) | Vanadium (V) | Tin (Sn) | |

| Ti-6Al-4V | Rest | 5.5%-6.8% | 3.5%-4.5% | |

| Ti-5Al-2.5Sn | Rest | 4.5%-5.5% | 2.0%-3.0% |

Physical Properties

| Density | 4.4-4.5g/cm³ |

| Melting Point | 1660°C |

| Coefficient of Thermal Expansion | 8-10×10⁻⁶/K (20°C-500°C) |

| Thermal Conductivity | 6-22 W/(m·K) (depending on alloy grade) |

| Electrical Resistivity | 0.14-0.17 μΩ·m |

| Tensile Strength | 600-1200 MPa (depending on alloy grade) |

| Yield Strength | 480-1100 MPa |

| Elongation at Break | 10%-25% |

| Hardness | 200-400 HB |

For more details, pls directly contact us.

When it comes to Grade 9 titanium tubes, we’re a cut above the rest. Many in the industry focus on mass production, which can lead to inconsistent quality or limited customization. We take a different approach, prioritizing precision and flexibility. Our tubes are manufactured to meet ASTM F136 and ISO standards, with rigorous testing to ensure they’re safe for medical use.

Unlike others, we offer tailored solutions—custom diameters, thicknesses, and surface finishes to match your implant design. Our seamless manufacturing process delivers tubes with exceptional uniformity, critical for high-stakes applications like stents or bone screws. While some cut corners to save costs, we invest in advanced techniques to balance quality and affordability, giving you the best value.

Our customer support is another edge. We work closely with you from design to delivery, ensuring your project meets regulatory and performance goals. Others might supply tubes, but we provide solutions that make your medical devices stand out.

Comparison Table: Grade 9 Titanium Tube vs. Other Materials

|

Parameter |

Grade 9 Titanium (Ti-3Al-2.5V) |

Stainless Steel |

Cobalt-Chromium |

|---|---|---|---|

|

Density (g/cm³) |

4.48 (Lightweight) |

7.9 (Heavy) |

8.3 (Heavier) |

|

Tensile Strength (MPa) |

860-900 |

500-1000 (Varies by alloy) |

800-1200 |

|

Corrosion Resistance |

Excellent (Body fluids) |

Good (Prone to pitting) |

Very Good |

|

Biocompatibility |

Excellent (Non-toxic) |

Moderate (Potential reactions) |

Good (Some limitations) |

|

Fatigue Resistance |

High |

Moderate to High |

High |

|

Cost |

Moderate to High |

Moderate |

High |

|

Weight Savings |

40% lighter than steel |

Heavy |

Heavier than titanium |

|

Applications |

Medical implants, aerospace |

Medical, industrial |

Medical, dental |

What makes our Grade 9 titanium tubes the best choice? It’s our focus on quality, customization, and innovation. We use state-of-the-art extrusion and testing to ensure every tube is flawless, with tight tolerances for precision implants. Our ability to customize is unmatched—whether you need micro-tubes for stents or larger ones for orthopedic devices, we deliver exactly what you need.

We’re also committed to sustainability, minimizing waste and energy use in our production process, which aligns with the medical industry’s push for eco-friendly practices. Our streamlined supply chain ensures fast, reliable delivery, keeping your project on schedule. And by leveraging cutting-edge manufacturing, we keep costs competitive without compromising on performance.

Looking Ahead

The medical implant industry is evolving fast, with demand for biocompatible, high-performance materials at an all-time high. Our Grade 9 titanium seamless tubes are ready to meet those demands, whether it’s for next-gen joint replacements, advanced dental implants, or life-saving stents. We’re constantly innovating, exploring new ways to enhance our tubes and support your medical breakthroughs.

Choose our Grade 9 titanium tubes for your medical implants, and you’re choosing reliability, safety, and a partner dedicated to your success. Let’s shape the future of healthcare together—one biocompatible tube at a time.

For more details, pls directly contact us.

About Us:

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications.

For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

FAQs:

-

What is Grade 9 titanium, and why is it used for medical implants?

Grade 9 titanium, or Ti-3Al-2.5V, is an alloy with 3% aluminum and 2.5% vanadium, offering high strength, light weight, and excellent biocompatibility, making it ideal for medical implants. -

How does Grade 9 titanium ensure biocompatibility?

It’s non-toxic, corrosion-resistant, and compatible with human tissue, preventing adverse reactions in the body for implants like bone screws and joint replacements. -

What medical applications use Grade 9 titanium tubes?

They’re used in orthopedic implants, dental implants, spinal fusion devices, and cardiovascular stents due to their strength and biocompatibility. -

How are Grade 9 titanium tubes manufactured?

They’re typically produced as seamless tubes through extrusion or rotary piercing, ensuring uniformity and strength for precision medical applications. -

How does Grade 9 titanium compare to other materials like stainless steel?

It’s lighter, more corrosion-resistant, and more biocompatible than stainless steel, with better fatigue resistance for long-term implants. -

Are Grade 9 titanium tubes cost-effective for medical use?

While initially more expensive, their durability, biocompatibility, and reduced need for replacement make them cost-effective over time. -

What industry standards do Grade 9 titanium tubes meet?

They comply with ASTM F136, ISO 5832-11, and other medical-grade standards, ensuring safety and reliability for implants. -

Can Grade 9 titanium tubes be customized for specific medical needs?

Yes, we offer custom diameters, wall thicknesses, and surface finishes to meet precise requirements for implants and medical devices.