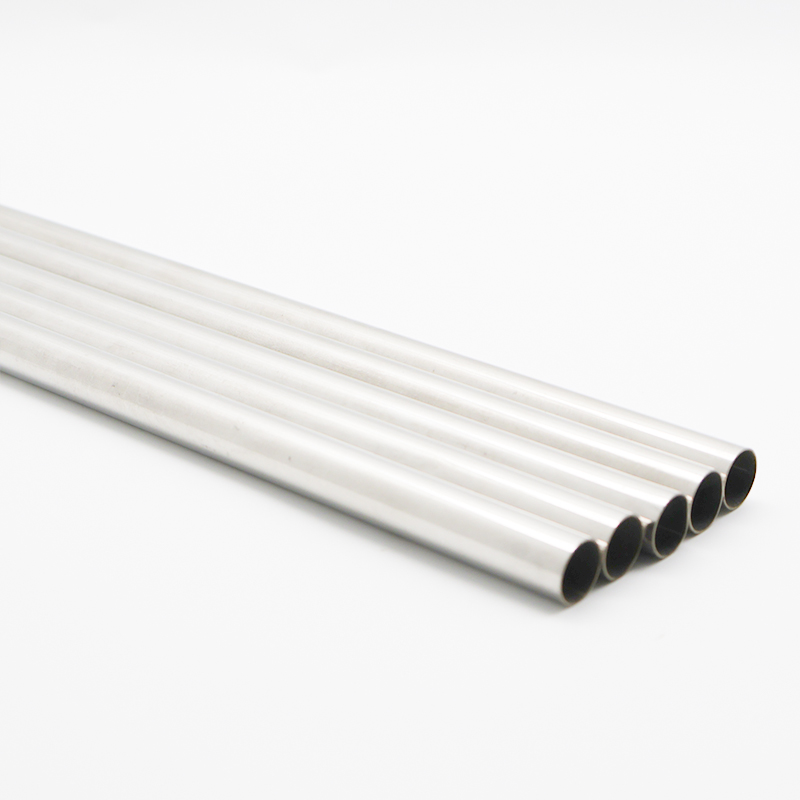

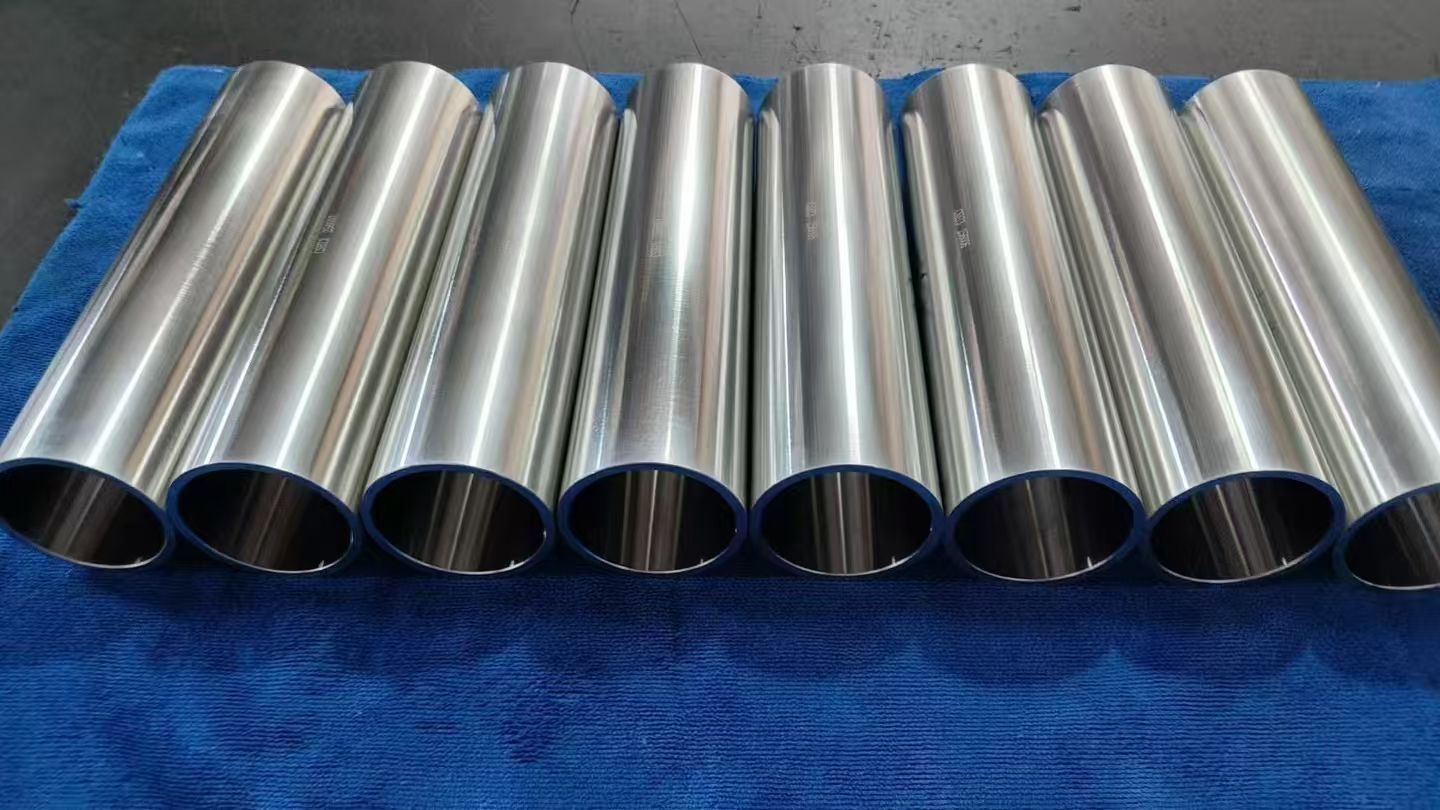

We’re proud to offer our high-strength Grade 5 Titanium Tube s, crafted from the renowned Ti-6Al-4V alloy. This material is a game-changer in aerospace, blending incredible strength with a lightweight build that’s 45% lighter than steel. With 6% aluminum and 4% vanadium, our Grade 5 titanium tubes deliver a tensile strength of 900-1000 MPa, making them tough enough for the most demanding aerospace applications. Whether it’s hydraulic systems, fuel lines, or airframe structures, these tubes are built to perform under pressure, resist corrosion, and handle extreme temperatures from -253°C to 600°C.

Our tubes meet stringent standards like ASTM B338 and AMS 4928, ensuring top-notch quality for aerospace projects. We provide both seamless and welded options, with seamless tubes offering superior strength for high-pressure systems and welded tubes providing cost-effective solutions for larger diameters. Plus, we can customize sizes, wall thicknesses, and finishes to fit your exact needs. From small-diameter hydraulic lines to robust structural components, our Grade 5 titanium tubes are designed to elevate your aerospace projects.

For more details, pls directly contact us.

Grade 5 titanium is the go-to choice for aerospace because it checks all the boxes: strength, weight, and durability. It’s as strong as many steels but nearly half the weight, which means better fuel efficiency and higher payloads for aircraft. Its corrosion resistance is a standout feature—whether it’s exposure to jet fuel, hydraulic fluids, or salty air, our tubes stay rust-free and reliable. This makes them perfect for everything from fighter jets to commercial airliners.

The alloy’s ability to handle extreme temperatures is another reason it’s a favorite. It holds up in the freezing cold of high-altitude flights and the intense heat of engine components. Add in its excellent fatigue resistance, and you’ve got a material that lasts longer, reducing maintenance costs and downtime. For aerospace engineers looking to push performance without compromising reliability, our Grade 5 titanium tubes are the answer.

Industry Analysis

The aerospace industry is soaring, driven by demand for fuel-efficient aircraft, advanced military systems, and space exploration. According to recent market trends, the global aerospace materials market is expected to grow at a CAGR of 6.5% through 2030, with titanium alloys like Grade 5 leading the charge. Why? Because airlines and manufacturers are under pressure to cut emissions and improve efficiency, and lightweight materials are key to making that happen.

Titanium’s role is expanding beyond traditional aircraft to drones, satellites, and even spacecraft. The push for sustainable aviation is also driving innovation, with companies seeking materials that reduce weight without sacrificing strength. Grade 5 titanium fits the bill perfectly, offering a balance of performance and longevity that’s hard to beat. Meanwhile, advancements in manufacturing—like additive manufacturing and precision extrusion—are making titanium tubes more cost-effective, opening doors to wider adoption.

However, challenges like high material costs and complex machining persist. That’s where we come in, streamlining production to deliver high-quality tubes at competitive prices. The industry’s future looks bright, with titanium remaining a cornerstone material as aerospace pushes toward greener, more efficient technologies.

| Titanium (Ti) | Aluminum (Al) | Vanadium (V) | Tin (Sn) | |

| Ti-6Al-4V | Rest | 5.5%-6.8% | 3.5%-4.5% | |

| Ti-5Al-2.5Sn | Rest | 4.5%-5.5% | 2.0%-3.0% |

Physical Properties

| Density | 4.4-4.5g/cm³ |

| Melting Point | 1660°C |

| Coefficient of Thermal Expansion | 8-10×10⁻⁶/K (20°C-500°C) |

| Thermal Conductivity | 6-22 W/(m·K) (depending on alloy grade) |

| Electrical Resistivity | 0.14-0.17 μΩ·m |

| Tensile Strength | 600-1200 MPa (depending on alloy grade) |

| Yield Strength | 480-1100 MPa |

| Elongation at Break | 10%-25% |

| Hardness | 200-400 HB |

For more details, pls directly contact us.

Our Grade 5 titanium tubes shine in a range of aerospace applications:

Hydraulic Systems: Their high strength and corrosion resistance make them ideal for high-pressure hydraulic lines in aircraft, ensuring leak-free performance.

Fuel Lines: Resistant to aggressive fuels and chemicals, these tubes keep fuel systems reliable in harsh conditions.

Airframe Structures: Lightweight and durable, they’re used in structural components to reduce aircraft weight while maintaining strength.

Engine Components: Their ability to withstand high temperatures makes them perfect for turbine and exhaust systems.

Spacecraft: From satellite frames to rocket fuel systems, Grade 5 titanium tubes deliver reliability in extreme environments.

These applications highlight why Grade 5 titanium is a staple in aerospace—it’s versatile, tough, and built to last.

Company Comparison

When it comes to Grade 5 titanium tubes, we stand out in a crowded market. Our competitors often focus on mass production, which can lead to inconsistent quality or limited customization. We take a different approach, prioritizing precision and flexibility. Our tubes are manufactured to exacting standards, with rigorous testing to ensure they meet ASTM and AMS requirements.

Unlike others, we offer tailored solutions—whether you need specific diameters, wall thicknesses, or surface finishes, we’ve got you covered. Our seamless tubes are crafted with advanced extrusion techniques for unmatched strength, while our welded tubes balance quality and affordability. We also invest in cutting-edge production methods to keep costs down without compromising performance, giving you the best value for your investment.

Our commitment to customer support sets us apart too. From design consultation to delivery, we work closely with you to ensure your project succeeds. While others may cut corners, we’re all about delivering reliable, high-performance titanium tubes that keep your aerospace projects flying high.

Comparison Table: Grade 5 Titanium Tube vs. Other Materials

Parameter | Grade 5 Titanium (Ti-6Al-4V) | Steel | Aluminum |

|---|---|---|---|

Density (g/cm³) | 4.43 (Lightweight) | 7.85 (Heavy) | 2.70 (Very Lightweight) |

Tensile Strength (MPa) | 900-1000 | 400-1200 (Varies by alloy) | 200-600 (Varies by alloy) |

Corrosion Resistance | Excellent (Resists fuels, chemicals) | Poor (Requires coatings) | Good (Susceptible to pitting) |

Temperature Range (°C) | -253 to 600 | -50 to 800 (Varies) | -200 to 300 |

Fatigue Resistance | High | Moderate to High | Moderate |

Cost | High | Moderate | Low to Moderate |

Weight Savings | 45% lighter than steel | Heavy | 30% lighter than titanium |

Applications | Aerospace, medical, marine | Construction, automotive | Aerospace, consumer goods |

What makes our Grade 5 titanium tubes the best choice? It’s our focus on quality, customization, and efficiency. We use state-of-the-art manufacturing to produce tubes with tight tolerances and consistent properties, ensuring they perform flawlessly in your applications. Our in-house expertise allows us to offer custom solutions that others can’t match, from unique sizes to specialized finishes.

We also prioritize sustainability, optimizing our processes to reduce waste and energy use, aligning with the aerospace industry’s push for greener solutions. Our supply chain is streamlined to deliver fast, reliable service, so you’re never left waiting. And with competitive pricing, we make high-performance titanium accessible without breaking your budget.

Looking Ahead

As the aerospace industry evolves, our Grade 5 titanium tubes are ready to meet the challenge. Whether you’re building the next generation of fuel-efficient airliners, cutting-edge drones, or spacecraft bound for Mars, our tubes deliver the strength, durability, and lightweight performance you need. We’re constantly innovating, exploring new ways to enhance our products and support your projects.

Choose our Grade 5 titanium tubes for your aerospace applications, and you’re choosing reliability, efficiency, and a partner committed to your success. Let’s build the future of aerospace together—one high-strength tube at a time.

For more details, pls directly contact us.

About Us:

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications.

For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

FAQs:

What is Grade 5 titanium, and why is it used for tubes in aerospace?

Grade 5 titanium, also known as Ti-6Al-4V, is an alloy with 6% aluminum and 4% vanadium, offering high strength, low weight, and excellent corrosion resistance. It’s used in aerospace for hydraulic systems, fuel lines, and structural components due to its durability and lightweight properties.What makes Grade 5 titanium tubes suitable for extreme environments?

These tubes withstand high temperatures (up to 600°C), resist corrosion from fuels and chemicals, and maintain structural integrity under stress, making them ideal for harsh aerospace conditions.How are Grade 5 titanium tubes manufactured?

They’re typically produced as seamless tubes through extrusion or rotary piercing, ensuring uniformity and strength, or as welded tubes for cost-effective larger diameters.What aerospace applications use Grade 5 titanium tubes?

They’re used in aircraft hydraulic systems, fuel lines, engine components, and airframe structures for their strength-to-weight ratio and reliability.How does Grade 5 titanium compare to other materials like steel or aluminum?

It’s 45% lighter than steel with comparable strength and more corrosion-resistant than aluminum, making it a top choice for aerospace performance.Are Grade 5 titanium tubes cost-effective for aerospace projects?

While more expensive upfront, their durability, low maintenance, and lightweight properties reduce fuel costs and extend service life, offering long-term savings.What industry standards do Grade 5 titanium tubes meet?

They comply with ASTM B338, ASME SB338, and aerospace-specific standards like AMS 4928, ensuring quality and performance.Can Grade 5 titanium tubes be customized for specific aerospace needs?

Yes, we offer custom sizes, wall thicknesses, and finishes to meet precise project requirements, from small-diameter hydraulic lines to large structural tubes.