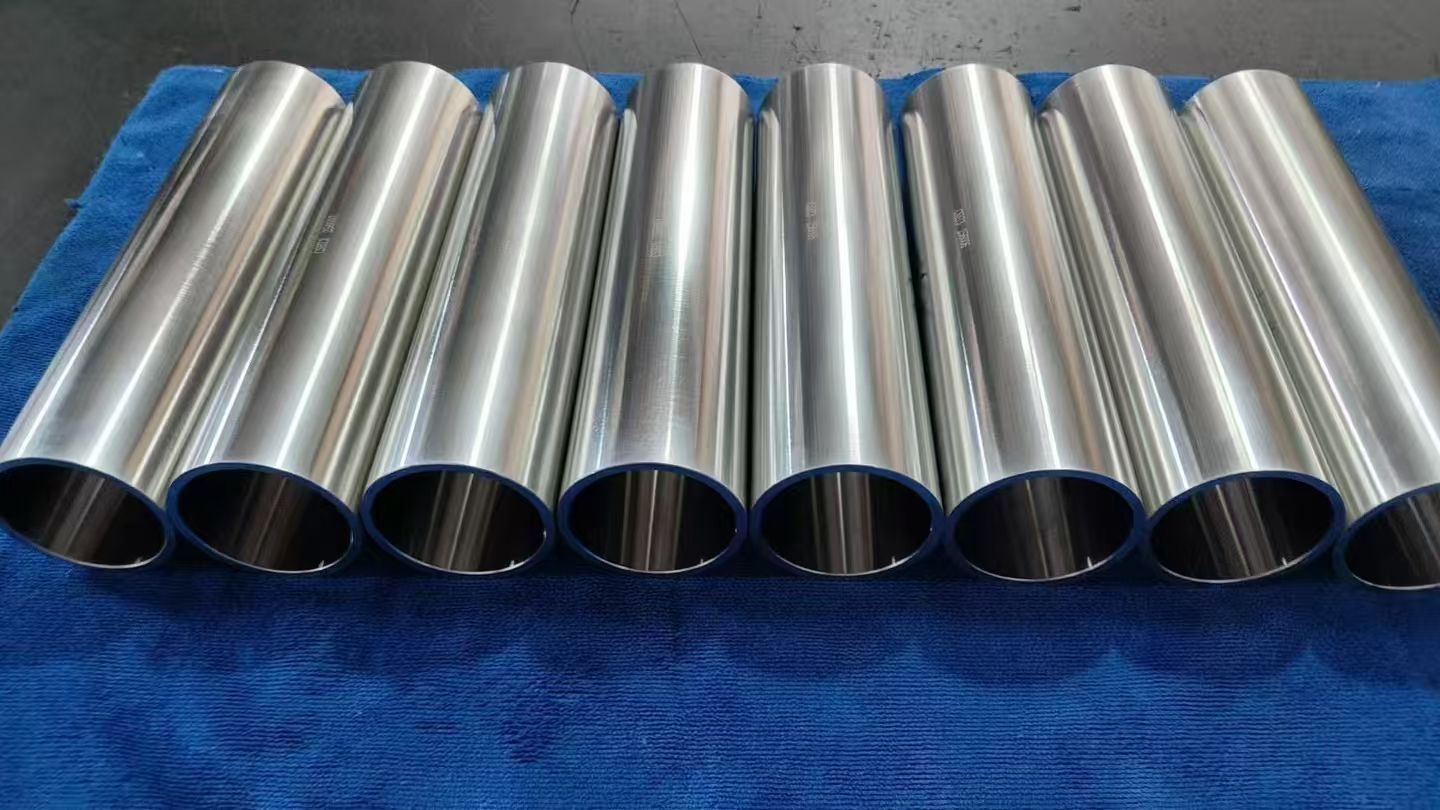

Our Grade 2 titanium seamless tubes are built for the toughest marine environments. Made from commercially pure titanium, these tubes are all about corrosion resistance, moderate strength, and reliability. They’re lightweight—40% lighter than stainless steel—and form a natural oxide layer that laughs in the face of saltwater, chlorides, and harsh marine conditions. With a tensile strength of 345-450 MPa, they’re strong enough for demanding applications but ductile enough for easy fabrication.

We craft these tubes using seamless processes like extrusion, ensuring a uniform structure that handles high-pressure systems without a hitch. They meet ASTM B338 and ASME SB338 standards, so you know they’re top quality. Whether you need small-diameter tubes for heat exchangers or larger ones for shipbuilding, we can customize sizes, wall thicknesses, and finishes to fit your project perfectly. Our Grade 2 titanium seamless tubes are your go-to for marine durability and performance.

For more details, pls directly contact us.

Grade 2 titanium is a superstar for marine use because it’s practically immune to corrosion. Seawater, salty air, and chemical exposure? No problem. The protective oxide layer keeps our tubes rust-free, even after years of exposure. They’re also lightweight, which is a big deal for marine applications where weight savings translate to better fuel efficiency and lower operating costs.

These tubes strike a perfect balance of strength and formability. They’re tough enough for structural components but easy to weld and shape, making them versatile for everything from piping to condenser tubes. Plus, they hold up in temperatures from -253°C to 400°C, so they’re reliable in the extreme conditions of marine environments, from icy waters to tropical seas.

| Titanium (Ti) | Aluminum (Al) | Vanadium (V) | Tin (Sn) | |

| Ti-6Al-4V | Rest | 5.5%-6.8% | 3.5%-4.5% | |

| Ti-5Al-2.5Sn | Rest | 4.5%-5.5% | 2.0%-3.0% |

Physical Properties

| Density | 4.4-4.5g/cm³ |

| Melting Point | 1660°C |

| Coefficient of Thermal Expansion | 8-10×10⁻⁶/K (20°C-500°C) |

| Thermal Conductivity | 6-22 W/(m·K) (depending on alloy grade) |

| Electrical Resistivity | 0.14-0.17 μΩ·m |

| Tensile Strength | 600-1200 MPa (depending on alloy grade) |

| Yield Strength | 480-1100 MPa |

| Elongation at Break | 10%-25% |

| Hardness | 200-400 HB |

For more details, pls directly contact us.

The marine industry is riding a wave of growth, with global demand for advanced materials expected to grow at a CAGR of 5.8% through 2030. Shipbuilding, offshore energy, and desalination are driving the need for materials that can withstand corrosive saltwater and harsh conditions. Titanium, especially Grade 2, is stealing the spotlight due to its unmatched corrosion resistance and lightweight properties.

Trends like sustainable shipping and offshore renewable energy are pushing the demand for durable, eco-friendly materials. Lightweight titanium reduces fuel consumption in vessels, aligning with green initiatives. Meanwhile, the rise of desalination plants and offshore platforms is increasing the need for reliable piping and heat exchanger tubes. However, high material costs and complex manufacturing can be hurdles. That’s where we shine, using advanced production techniques to deliver high-quality tubes at competitive prices.

The industry is also seeing innovations in titanium processing, like precision seamless manufacturing, which improves performance and reduces waste. As marine applications become more specialized, our ability to offer customized solutions keeps us ahead of the curve.

Applications in Marine Environments

Our Grade 2 titanium seamless tubes are a perfect fit for a range of marine applications:

-

Heat Exchangers: Their corrosion resistance and thermal conductivity make them ideal for cooling systems in ships and offshore platforms.

-

Desalination Plants: They handle salty, high-pressure water without corroding, ensuring long-term reliability.

-

Shipbuilding: Used in piping systems and structural components, they reduce weight and boost durability.

-

Offshore Platforms: Perfect for subsea piping and equipment exposed to harsh ocean conditions.

-

Marine HVAC Systems: Their resistance to corrosion ensures efficient, long-lasting performance in heating and cooling systems.

These applications show why Grade 2 titanium is a marine industry favorite—it’s tough, reliable, and built to last in the harshest conditions.

Company Comparison

In the world of titanium tubes, we stand out by focusing on quality, customization, and value. Many in the industry churn out standard products with little flexibility, but we’re different. Our Grade 2 titanium seamless tubes are crafted with precision, meeting strict ASTM and ASME standards through rigorous testing. We don’t just make tubes; we tailor them to your needs, offering custom diameters, thicknesses, and finishes to match your marine project’s specs.

Our seamless manufacturing process ensures uniformity and strength, perfect for high-pressure systems. While others might skimp on quality to cut costs, we use cutting-edge techniques to keep prices competitive without sacrificing performance. Our welded tube options are also available for projects where cost-efficiency is key, but seamless is where we excel for marine durability.

We also pride ourselves on customer support. From initial design to final delivery, we’re with you every step, ensuring your project runs smoothly. Our competitors might deliver tubes, but we deliver solutions that keep your marine systems running strong.

Comparison Table: Grade 2 Titanium Seamless Tube vs. Other Materials

|

Parameter |

Grade 2 Titanium |

Stainless Steel |

Copper-Nickel |

|---|---|---|---|

|

Density (g/cm³) |

4.51 (Lightweight) |

7.9 (Heavy) |

8.94 (Heavier) |

|

Tensile Strength (MPa) |

345-450 |

500-700 (Varies by alloy) |

300-400 |

|

Corrosion Resistance |

Excellent (Seawater, chlorides) |

Good (Prone to pitting) |

Good (Less durable) |

|

Temperature Range (°C) |

-253 to 400 |

-50 to 800 |

-50 to 300 |

|

Fatigue Resistance |

Moderate to High |

High |

Moderate |

|

Cost |

Moderate to High |

Moderate |

Low to Moderate |

|

Weight Savings |

40% lighter than steel |

Heavy |

Heavier than titanium |

|

Applications |

Marine, chemical, medical |

Marine, construction |

Marine, heat exchangers |

What sets our Grade 2 titanium seamless tubes apart? It’s our commitment to excellence. We use state-of-the-art extrusion and testing to ensure every tube meets the highest standards for corrosion resistance and strength. Our customization options are unmatched—whether you need a specific size for a desalination plant or a unique finish for a ship’s piping, we make it happen.

Sustainability is also a big part of our story. We optimize our production to minimize waste and energy use, aligning with the marine industry’s push for greener solutions. Our streamlined supply chain means fast delivery, so your project stays on track. And by leveraging advanced manufacturing, we keep costs down, making high-performance titanium accessible for your budget.

Looking Ahead

The marine industry is evolving, with demands for durability, efficiency, and sustainability at an all-time high. Our Grade 2 titanium seamless tubes are ready to meet those challenges, whether it’s for next-gen ships, offshore wind farms, or desalination systems. We’re constantly innovating, exploring new ways to enhance our tubes and support your projects.

Choose our Grade 2 titanium seamless tubes for your marine applications, and you’re getting reliability, performance, and a partner dedicated to your success. Let’s tackle the toughest marine challenges together—one corrosion-resistant tube at a time.

For more details, pls directly contact us.

About Us:

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications.

For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

FAQs:

-

What is Grade 2 titanium, and why is it ideal for marine applications?

Grade 2 titanium is commercially pure titanium with excellent corrosion resistance, moderate strength, and good weldability, making it perfect for marine environments like seawater and salty air. -

How do Grade 2 titanium seamless tubes resist corrosion in marine settings?

They form a protective oxide layer that prevents rust and degradation, even in harsh conditions like saltwater, chlorides, and high humidity. -

What marine applications use Grade 2 titanium seamless tubes?

They’re used in heat exchangers, desalination plants, shipbuilding, and offshore platforms for piping, condenser tubes, and structural components. -

How are Grade 2 titanium seamless tubes manufactured?

They’re produced through extrusion or rotary piercing, ensuring a uniform structure with no welds, ideal for high-pressure and corrosive marine systems. -

How does Grade 2 titanium compare to stainless steel for marine use?

Grade 2 titanium offers superior corrosion resistance and is 40% lighter than stainless steel, with better longevity in saltwater environments. -

Are Grade 2 titanium seamless tubes cost-effective for marine projects?

Though initially pricier, their long lifespan, low maintenance, and resistance to corrosion make them a cost-saving choice over time. -

What industry standards do Grade 2 titanium seamless tubes meet?

They comply with ASTM B338, ASME SB338, and marine-specific standards, ensuring reliability and quality for marine applications. -

Can Grade 2 titanium seamless tubes be customized for specific marine needs?

Yes, we offer custom diameters, wall thicknesses, and lengths to meet precise requirements for marine systems like heat exchangers or piping.