Pure Nickel Wire Ni200 is one of the most reliable and versatile materials for industrial and electrochemical applications. At DLX, we manufacture and supply factory-direct pure nickel wire to B2B customers worldwide, supporting industries that demand stable performance, consistent quality, and long-term supply reliability.

Ni200 is classified as commercially pure nickel, offering an ideal balance of corrosion resistance, electrical conductivity, and mechanical workability. This combination makes it a preferred material for industrial heating elements, electroplating anodes, battery tabs, sensors, and chemical equipment components.

From raw material control to final inspection, DLX focuses on delivering pure nickel wire that meets international standards and real-world industrial requirements.

For more details, pls directly contact us.

One of the key reasons pure nickel wire remains in high demand is its chemical stability. Ni200 performs exceptionally well in alkaline environments, which is why it is commonly used in electroplating tanks and chemical processing systems. Unlike many alloy materials, pure nickel does not easily contaminate plating baths, helping customers maintain consistent product quality.

Electrical conductivity is another major advantage. While not as conductive as copper, Ni200 provides stable and predictable electrical performance under heat and chemical exposure, making it suitable for heating elements and electrical components operating in harsh conditions.

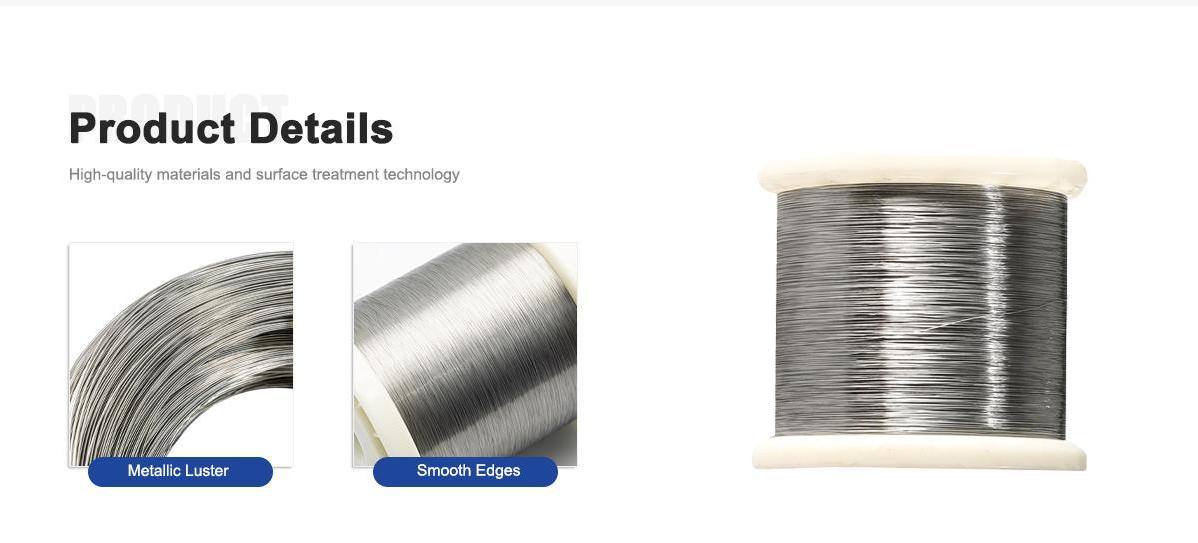

From a processing standpoint, pure nickel wire is easy to draw, weld, and form. DLX offers both annealed and hard-drawn conditions to match different production needs, whether for flexible lead wires or structural heating components.

| Grade | Nickel (Ni)+ Cobalt (Co) | Copper (Cu) | Silicon (Si) | Manganese (Mn) | Carbon (C) | Magnesium (Mg) | Sulfur (S) | Phosphorus (P) | Iron (Fe) |

|

|

99.9% | ≤0.015 | ≤0.03 | ≤0.002 | ≤0.01 | ≤0.01 | ≤0.001 | ≤0.001 | ≤0.04 |

|

|

99.6% | 0.1 | 0.1 | 0.05 | 0.1 | 0.1 | 0.005 | 0.002 | 0.1 |

Physical & Mechanical Properties

| Grades | N4/Ni201 | N6/Ni200 |

| Density | 8.9g/cm³ | 8.9g/cm³ |

| Melting Point | 1455°C | 1445-1470℃ |

| Coefficient of Thermal Expansion | 13.0µm/m·°C | 13.3×10⁻⁶/℃ |

| Thermal Conductivity | 10.1W/m·K | 90.7 W/m·K |

| Electrical Resistivity | 0.103×10⁻⁶Ω·/m (at 20℃) | |

| Electrical Conductivity | 14.6% IACS | |

| Tensile Strength | ≥450MPa | ≥450 MPa |

| Yield Strength | ≥200MPa | ≥150 MPa |

| Elongation at Break | ≥40% | ≥40% |

| Hardness | ≤150 |

For more details, pls directly contact us.

Electroplating is one of the largest application sectors for pure nickel wire. Ni200 is widely used as nickel anodes in plating baths due to its uniform dissolution rate and stable chemical behavior. This directly improves coating consistency and reduces waste for plating operators.

In the battery industry, pure nickel wire is used for tabs, connectors, and current collectors, especially in lithium battery and energy storage systems. Its purity ensures low internal resistance and long-term reliability.

Additional applications include sensors, thermocouple components, hydrogen systems, chemical reactors, and OEM electrical assemblies where material stability is essential.

Pure Nickel Wire Ni200 – Technical Comparison Table

| Parameter | Ni200 (UNS N02200) | Ni201 (UNS N02201) |

|---|---|---|

| Nickel Content | ≥ 99.6% | ≥ 99.6% |

| Carbon Content | ≤ 0.15% | ≤ 0.02% |

| Standard | ASTM B160 / DIN 2.4060 | ASTM B160 / DIN 2.4066 |

| Electrical Resistivity | ~0.096 μΩ·m | ~0.096 μΩ·m |

| Density | 8.89 g/cm³ | 8.89 g/cm³ |

| Max Service Temperature | ~600°C | ~800°C |

| Corrosion Resistance | Excellent | Excellent |

| Typical Applications | Electroplating, heating, batteries | High-temperature processing |

With the growth of新能源、electrochemical processing, and industrial automation, demand for high-purity nickel materials continues to rise. Electroplating capacity expansion, battery manufacturing investments, and hydrogen-related infrastructure are driving consistent global demand for pure nickel wire.

B2B buyers are increasingly focused on supplier reliability, material traceability, and customization capabilities rather than just price. This shift favors manufacturers like DLX that control production in-house and can support long-term partnerships.

Another trend is the growing demand for compliance with multiple international standards. DLX pure nickel wire is produced to meet ASTM, DIN, JIS, and GB requirements, simplifying sourcing for international customers.

DLX vs Typical Market Suppliers

Many suppliers in the market act as traders with limited control over raw materials and production consistency. This often results in fluctuating quality, inconsistent wire diameter, and unstable delivery times.

At DLX, pure nickel wire is produced under controlled processes with strict inspection standards. From chemical composition analysis to dimensional tolerance checks, every batch is verified before shipment. This reduces risk for B2B customers who rely on stable supply chains.

We also offer flexible MOQ, OEM customization, and technical support based on real industrial application experience—not just catalog data. This practical approach helps customers reduce trial costs and accelerate project timelines.

Why B2B Customers Choose DLX Pure Nickel Wire

DLX focuses on long-term cooperation rather than one-time transactions. Factory-direct pricing, stable production capacity, and responsive communication allow us to support wholesalers, OEM manufacturers, and industrial project contractors efficiently.

Our pure nickel wire is supplied with full material certification, consistent batch control, and packaging designed for industrial handling and export logistics.

Whether the requirement is electroplating anodes, industrial heating wire, or precision electrical components, DLX delivers pure nickel wire that performs reliably in real operating conditions.

For more details, pls directly contact us.

About Us:

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications.

For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

FAQ – Pure Nickel Wire Ni200 (UNS N02200)

1. What material is Ni200 pure nickel wire made from?

Ni200 pure nickel wire is made from commercially pure nickel with a minimum nickel content of 99.6%. It contains very low levels of carbon, sulfur, and other impurities, which gives it excellent corrosion resistance, stable electrical conductivity, and strong performance in alkaline and neutral environments.

2. What is the difference between Ni200 and Ni201?

Ni200 has slightly higher carbon content than Ni201, making it suitable for most industrial applications. Ni201 has ultra-low carbon and is preferred for extremely high-temperature environments where carbon precipitation must be avoided. For electroplating and heating elements below 600°C, Ni200 is the most commonly selected grade.

3. Which standards does Ni200 pure nickel wire comply with?

Ni200 pure nickel wire typically complies with ASTM B160, ASTM B162, UNS N02200, DIN 2.4060, JIS NW2200, and GB/T 2054 standards, making it suitable for global B2B procurement and international projects.

4. What industries commonly use pure nickel wire?

Pure nickel wire is widely used in industrial heating, electroplating equipment, battery manufacturing, chemical processing, hydrogen systems, electronics, sensors, and OEM electrical components where corrosion resistance and conductivity are critical.

5. Is Ni200 suitable for electroplating applications?

Yes. Ni200 pure nickel wire is one of the most widely used materials for electroplating anodes due to its excellent dissolution behavior, chemical stability, and consistent purity, which helps maintain plating bath quality.

6. What forms and sizes can DLX supply?

DLX supplies pure nickel wire in annealed or hard condition, with diameters ranging from ultra-fine wire to heavy industrial wire. Customized diameters, spool sizes, cut lengths, and packaging are available for B2B customers.

7. How does pure nickel wire perform in corrosive environments?

Ni200 shows excellent resistance to alkalis, neutral salts, and many organic acids. It performs especially well in caustic soda environments, making it a preferred choice for chemical processing and electroplating lines.

8. Is pure nickel wire suitable for OEM and bulk orders?

Absolutely. Pure nickel wire is ideal for OEM manufacturing due to its stable properties, repeatable quality, and compatibility with automated production lines. DLX supports bulk orders, long-term supply contracts, and customized specifications.