Pure Nickel Wire DIN 2.4060 and DIN 2.4066 plays a critical role in modern battery manufacturing and electrical component production. At DLX, we supply factory-direct pure nickel wire to battery tab producers and electrical component wholesalers who need stable quality, predictable performance, and long-term supply reliability.

As battery technologies continue to evolve, material consistency becomes more important than ever. Pure nickel wire provides a proven balance of conductivity, corrosion resistance, and mechanical stability, making it a trusted material across lithium battery, energy storage, and electronics industries.

From our perspective, pure nickel wire is not just a raw material. It is a functional component that directly affects production efficiency, welding quality, and final product reliability.

For more details, pls directly contact us.

Battery tab production places very specific demands on materials. The wire must conduct electricity efficiently, weld consistently, and maintain structural integrity over repeated charge and discharge cycles. Pure nickel wire meets these requirements better than many alternative materials.

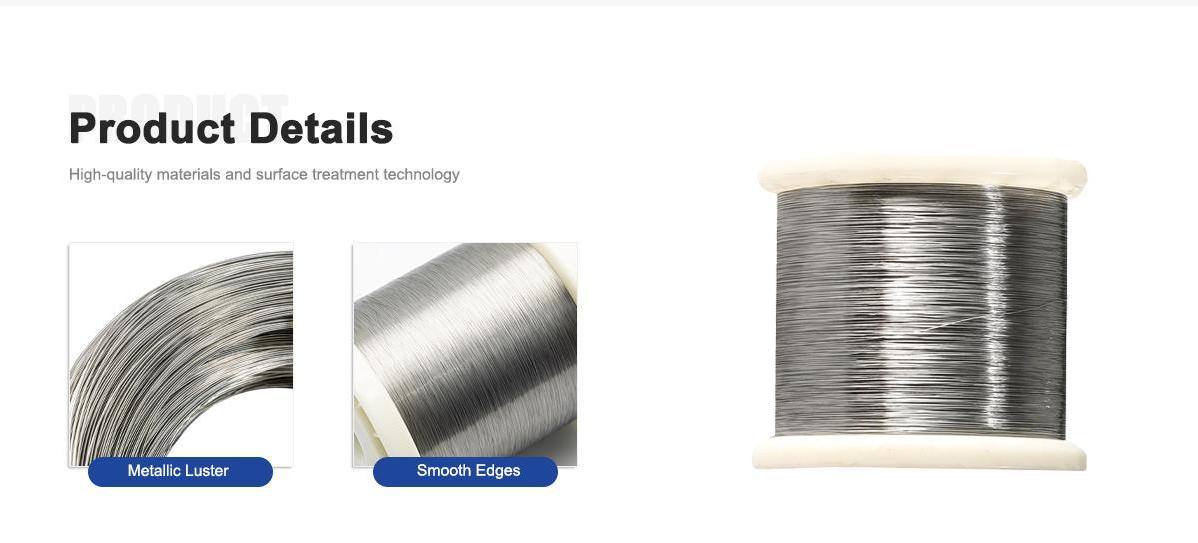

DIN 2.4060 pure nickel wire offers excellent ductility and surface cleanliness, which helps ensure stable spot welding performance. This reduces welding defects and improves yield rates on automated battery production lines.

DIN 2.4066, with its lower carbon content, offers additional stability during high-temperature processing steps. For battery manufacturers pushing higher energy density or operating temperatures, this grade provides extra process security.

At DLX, we pay close attention to surface finish and dimensional tolerance, because even small inconsistencies can impact battery tab performance at scale.

| Grade | Nickel (Ni)+ Cobalt (Co) | Copper (Cu) | Silicon (Si) | Manganese (Mn) | Carbon (C) | Magnesium (Mg) | Sulfur (S) | Phosphorus (P) | Iron (Fe) |

|

|

99.9% | ≤0.015 | ≤0.03 | ≤0.002 | ≤0.01 | ≤0.01 | ≤0.001 | ≤0.001 | ≤0.04 |

|

|

99.6% | 0.1 | 0.1 | 0.05 | 0.1 | 0.1 | 0.005 | 0.002 | 0.1 |

Physical & Mechanical Properties

| Grades | N4/Ni201 | N6/Ni200 |

| Density | 8.9g/cm³ | 8.9g/cm³ |

| Melting Point | 1455°C | 1445-1470℃ |

| Coefficient of Thermal Expansion | 13.0µm/m·°C | 13.3×10⁻⁶/℃ |

| Thermal Conductivity | 10.1W/m·K | 90.7 W/m·K |

| Electrical Resistivity | 0.103×10⁻⁶Ω·/m (at 20℃) | |

| Electrical Conductivity | 14.6% IACS | |

| Tensile Strength | ≥450MPa | ≥450 MPa |

| Yield Strength | ≥200MPa | ≥150 MPa |

| Elongation at Break | ≥40% | ≥40% |

| Hardness | ≤150 |

For more details, pls directly contact us.

In electrical systems, pure nickel wire offers predictable resistance values and good corrosion resistance, which is especially important in humid or chemically active environments. Its compatibility with welding and soldering processes makes it easy to integrate into complex assemblies.

Electrical component wholesalers value pure nickel wire for its versatility. A single material grade can support multiple end-use products, simplifying inventory management and procurement planning.

Industry Trends Driving Demand for Pure Nickel Wire

The global growth of lithium batteries, energy storage systems, and electric devices is driving steady demand for pure nickel wire. Battery manufacturers are expanding capacity, and their suppliers are looking for materials that support high-volume, automated production with minimal variability.

Another trend is the increasing focus on quality traceability. Battery and electronics customers are demanding clearer material documentation and tighter batch control. This favors manufacturers like DLX that produce pure nickel wire in-house and maintain full quality records.

Sustainability is also influencing material selection. Pure nickel is fully recyclable, and its long service life aligns well with the industry’s move toward more sustainable production models.

Pure Nickel Wire DIN 2.4060 / 2.4066 – Technical Comparison Table

| Parameter | DIN 2.4060 (Ni200) | DIN 2.4066 (Ni201) |

|---|---|---|

| Nickel Content | ≥ 99.6% | ≥ 99.6% |

| Carbon Content | ≤ 0.15% | ≤ 0.02% |

| Equivalent Standard | UNS N02200 / ASTM B160 | UNS N02201 / ASTM B160 |

| Density | 8.89 g/cm³ | 8.89 g/cm³ |

| Electrical Resistivity | ~0.096 μΩ·m | ~0.096 μΩ·m |

| Max Recommended Temperature | ~600°C | ~800°C |

| Weldability | Excellent | Excellent |

| Typical Applications | Battery tabs, connectors | High-temp battery & electronics |

Many pure nickel wire suppliers operate as distributors, sourcing material from different mills depending on price. This can lead to inconsistent surface condition, fluctuating mechanical properties, and variation between batches.

At DLX, pure nickel wire DIN 2.4060 and 2.4066 is produced under controlled processes with consistent raw material sourcing. Each batch is tested for chemical composition, mechanical properties, and dimensional accuracy before shipment.

We also understand the practical needs of battery and electrical manufacturers. Instead of offering generic specifications, we work with customers to match wire condition, size, and packaging to real production requirements.

Why Battery and Electrical Wholesalers Choose DLX

DLX supports wholesalers who need stable supply, competitive factory-direct pricing, and responsive communication. Our production capacity allows us to support both bulk orders and repeat shipments without compromising quality.

We offer flexible MOQ, customized spooling, and packaging designed for warehouse handling and export logistics. Full material certification is provided to support downstream customer requirements.

By working with DLX, wholesalers gain a reliable source of pure nickel wire that can be confidently supplied to battery manufacturers and electrical component producers.

Long-Term Value of Pure Nickel Wire Supply

In battery and electrical industries, supply stability is just as important as material performance. Delays or quality issues can interrupt entire production lines.

DLX focuses on long-term partnerships rather than short-term transactions. Our goal is to help customers standardize their pure nickel wire supply, reduce qualification cycles, and improve overall production efficiency.

With consistent quality, technical understanding, and factory-direct support, DLX pure nickel wire DIN 2.4060 / 2.4066 delivers long-term value across the battery and electrical supply chain.

For more details, pls directly contact us.

About Us:

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications.

For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

1. What is DIN 2.4060 and DIN 2.4066 pure nickel wire?

DIN 2.4060 and DIN 2.4066 are German standard grades for commercially pure nickel wire. DIN 2.4060 corresponds to Ni200, while DIN 2.4066 corresponds to Ni201. Both offer high nickel purity (≥99.6%), with the main difference being carbon content and high-temperature performance.

2. Why is pure nickel wire widely used for battery tabs?

Pure nickel wire offers stable electrical conductivity, excellent weldability, and low contact resistance. These properties make it ideal for battery tab production, where reliable current transfer and consistent spot welding quality are critical.

3. What is the difference between DIN 2.4060 and DIN 2.4066 in battery applications?

DIN 2.4060 (Ni200) is commonly used for general battery tab and electrical component production. DIN 2.4066 (Ni201) has lower carbon content and is preferred when higher temperature exposure or longer service life is required during manufacturing or operation.

4. Which international standards are equivalent to these DIN grades?

DIN 2.4060 is equivalent to UNS N02200 and ASTM B160 Ni200. DIN 2.4066 corresponds to UNS N02201 and ASTM B160 Ni201. This allows easy material substitution for global battery and electronics supply chains.

5. Is pure nickel wire suitable for automated battery production lines?

Yes. Pure nickel wire has consistent mechanical properties and surface quality, making it highly compatible with automated cutting, stamping, and welding equipment used in battery tab production.

6. What diameters and forms can DLX supply?

DLX supplies pure nickel wire in fine wire, round wire, flat wire, and customized battery tab formats. Diameter, temper, and spool configuration can be adjusted to match specific production requirements.

7. How does pure nickel perform in electrical components?

Pure nickel provides stable conductivity, excellent corrosion resistance, and good solderability. It is widely used in connectors, lead wires, sensors, and precision electrical components.

8. Is pure nickel wire suitable for wholesale and long-term supply?

Absolutely. Pure nickel wire is a standardized material with stable demand. DLX supports wholesalers with bulk supply, consistent batch control, and long-term delivery planning.