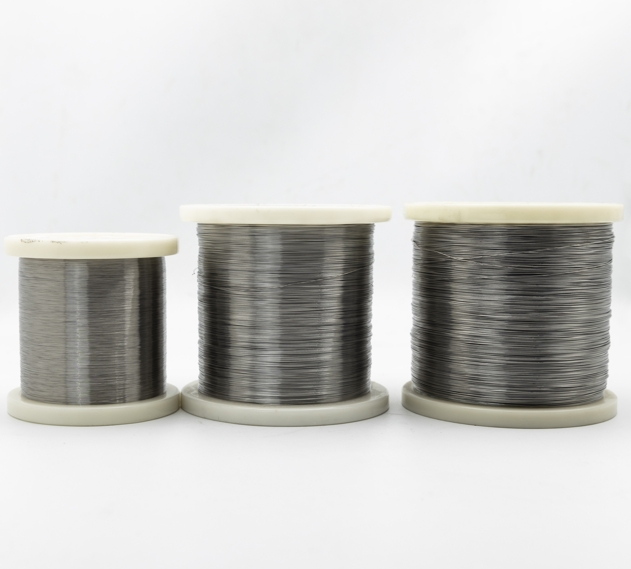

High purity nickel wire Ni201 is a material developed for demanding industrial environments where temperature stability, chemical resistance, and material purity are critical. At DLX, we manufacture and supply Ni201 nickel wire for chemical processing and energy equipment manufacturers who need reliable performance over long service cycles.

Ni201 is not just a higher-grade version of pure nickel. Its ultra-low carbon content makes it the preferred choice for applications involving sustained high temperatures, especially in chemical reactors, heat exchangers, and energy-related systems. From a manufacturing standpoint, this stability reduces maintenance cycles and lowers the risk of unexpected material failure.

As a factory-direct supplier, DLX controls every stage of production, from raw material selection to final inspection.

For more details, pls directly contact us.

The defining feature of Ni201 nickel wire is its resistance to high-temperature degradation. In environments above 600°C, standard pure nickel materials may suffer from carbon-related embrittlement. Ni201 eliminates this risk, ensuring structural and electrical stability even during continuous operation.

Ni201 also maintains excellent corrosion resistance in alkaline and neutral chemical environments. This makes it suitable for chemical processing equipment that handles caustic solutions, as well as energy systems operating under aggressive chemical conditions.

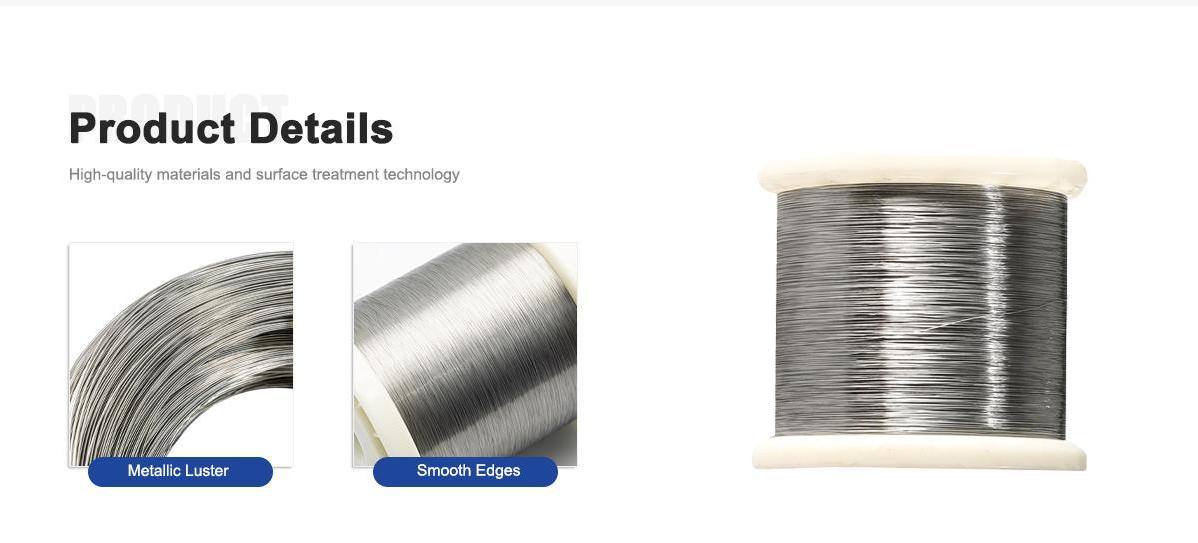

From a mechanical perspective, Ni201 nickel wire offers good ductility and formability. It can be easily bent, welded, or drawn into precise shapes, which is essential for OEM manufacturers integrating the wire into complex assemblies.

Applications in Chemical Processing Equipment

In chemical processing industries, Ni201 nickel wire is commonly used in heaters, sensors, support components, and specialized wire elements exposed to both heat and chemicals. Its purity ensures that it does not introduce contaminants into sensitive chemical processes.

Ni201 is especially suitable for alkaline chemical environments, such as caustic soda production and chemical transport systems. The wire’s resistance to corrosion and oxidation improves equipment lifespan and reduces downtime for maintenance.

For OEM chemical equipment manufacturers, consistent material quality is critical. DLX nickel wire is produced with tight dimensional tolerances and stable chemical composition to ensure predictable performance across production batches.

| Grade | Nickel (Ni)+ Cobalt (Co) | Copper (Cu) | Silicon (Si) | Manganese (Mn) | Carbon (C) | Magnesium (Mg) | Sulfur (S) | Phosphorus (P) | Iron (Fe) |

| 99.9% | ≤0.015 | ≤0.03 | ≤0.002 | ≤0.01 | ≤0.01 | ≤0.001 | ≤0.001 | ≤0.04 | |

| 99.6% | 0.1 | 0.1 | 0.05 | 0.1 | 0.1 | 0.005 | 0.002 | 0.1 |

Physical & Mechanical Properties

| Grades | N4/Ni201 | N6/Ni200 |

| Density | 8.9g/cm³ | 8.9g/cm³ |

| Melting Point | 1455°C | 1445-1470℃ |

| Coefficient of Thermal Expansion | 13.0µm/m·°C | 13.3×10⁻⁶/℃ |

| Thermal Conductivity | 10.1W/m·K | 90.7 W/m·K |

| Electrical Resistivity | 0.103×10⁻⁶Ω·/m (at 20℃) | |

| Electrical Conductivity | 14.6% IACS | |

| Tensile Strength | ≥450MPa | ≥450 MPa |

| Yield Strength | ≥200MPa | ≥150 MPa |

| Elongation at Break | ≥40% | ≥40% |

| Hardness | ≤150 |

For more details, pls directly contact us.

The energy sector is one of the fastest-growing application areas for Ni201 nickel wire. It is widely used in hydrogen-related equipment, alkaline electrolysis systems, and energy conversion devices where high temperature and chemical exposure coexist.

Ni201 performs well in controlled atmospheres and vacuum environments, making it suitable for advanced energy systems and experimental equipment. Its electrical stability also supports use in heating elements and current-carrying components within energy devices.

As global investment in clean energy and hydrogen infrastructure continues to increase, demand for high-purity nickel materials like Ni201 is expected to grow steadily.

Ni201 High Purity Nickel Wire – Technical Comparison Table

| Parameter | Ni201 (UNS N02201) | Ni200 (UNS N02200) |

|---|---|---|

| Nickel Content | ≥ 99.6% | ≥ 99.6% |

| Carbon Content | ≤ 0.02% | ≤ 0.15% |

| Standard | ASTM B160 / DIN 2.4066 | ASTM B160 / DIN 2.4060 |

| Density | 8.89 g/cm³ | 8.89 g/cm³ |

| Electrical Resistivity | ~0.096 μΩ·m | ~0.096 μΩ·m |

| Max Recommended Temp | ~800°C | ~600°C |

| Corrosion Resistance | Excellent | Excellent |

| Typical Applications | Chemical, energy, high-temp systems | General industrial use |

Several industry trends are contributing to rising demand for Ni201 nickel wire. Chemical processing plants are operating at higher temperatures and stricter efficiency standards, increasing the need for low-carbon, high-purity materials.

In the energy sector, hydrogen production and storage systems require materials that can withstand alkaline environments and elevated temperatures without performance degradation. Ni201 fits these requirements well.

Another major trend is the shift toward long-term supplier partnerships. B2B customers are prioritizing consistent quality, traceability, and technical support over short-term pricing advantages. This trend aligns closely with DLX’s factory-direct and quality-driven approach.

DLX vs Typical Market Suppliers

Many suppliers offer nickel wire as a trading product, relying on external mills with limited quality control. This often results in inconsistent wire diameter, surface condition issues, and unstable chemical composition.

At DLX, Ni201 nickel wire is produced under strict internal controls. Chemical composition is verified for every batch, and dimensional accuracy is checked throughout the production process. This ensures that OEM manufacturers receive wire that integrates smoothly into automated production lines.

DLX also provides practical technical support based on real industrial applications, helping customers select the correct wire condition and specification for their equipment.

Why Chemical and Energy Equipment Manufacturers Choose DLX

DLX focuses on long-term reliability rather than short-term sales. Our OEM-oriented approach allows chemical and energy equipment manufacturers to standardize materials and reduce qualification costs.

We offer flexible MOQ, customized specifications, stable delivery schedules, and export-ready packaging. Full material certification and traceability are provided to support quality audits and international compliance.

By working directly with DLX, customers gain a reliable partner who understands industrial applications, production realities, and long-term supply requirements.

For more details, pls directly contact us.

About Us:

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications.

For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

1. What is Ni201 high purity nickel wire?

Ni201 is a commercially pure nickel material with a minimum nickel content of 99.6% and extremely low carbon content. Compared with Ni200, Ni201 is designed specifically for high-temperature environments where carbon embrittlement must be avoided, making it ideal for chemical processing and energy equipment.

2. Why is low carbon important in Ni201?

The carbon content in Ni201 is typically limited to 0.02% max. This prevents graphite precipitation at elevated temperatures, which significantly improves long-term stability when the wire is exposed to temperatures above 600°C in chemical reactors or energy systems.

3. Which standards does Ni201 nickel wire follow?

Ni201 nickel wire is commonly produced according to ASTM B160, UNS N02201, DIN 2.4066, JIS NW2201, and GB/T standards. This allows manufacturers to use the same material across international projects without requalification.

4. What industries typically use Ni201 nickel wire?

Ni201 is widely used in chemical processing equipment, energy systems, hydrogen production, alkaline environments, heat exchangers, and OEM industrial components that operate at elevated temperatures.

5. Is Ni201 suitable for chemical corrosion environments?

Yes. Ni201 offers excellent resistance to caustic alkalis, neutral salts, and many organic chemicals. It is particularly suitable for chemical processing lines where corrosion resistance and thermal stability are both required.

6. Can DLX provide OEM and customized nickel wire?

DLX specializes in OEM supply. We offer customized wire diameters, surface conditions, spool sizes, and packaging to meet the exact needs of chemical and energy equipment manufacturers.

7. What surface conditions are available?

Ni201 nickel wire can be supplied in annealed, bright annealed, or hard-drawn condition, depending on forming, welding, or electrical requirements.

8. Is Ni201 suitable for long-term industrial supply contracts?

Yes. Ni201 nickel wire is commonly used in long-term industrial projects. DLX supports stable batch control, consistent chemical composition, and long-term supply agreements for B2B customers.