Our aerospace-grade Titanium Plate s are engineered to meet the rigorous demands of modern aircraft manufacturing. Known for their exceptional strength-to-weight ratio, corrosion resistance, and ability to perform under extreme conditions, these plates are a cornerstone in building reliable and efficient aircraft. We craft them using high-quality titanium alloys, primarily Ti-6Al-4V (Grade 5), which dominates the aerospace sector due to its balanced strength, ductility, and fatigue resistance. Whether it’s for airframes, landing gear, or engine components, our titanium plates deliver unmatched performance, helping aircraft soar lighter, stronger, and longer.

Each plate is produced with precision, adhering to strict standards like ASTM B265 and AMS 4911, ensuring consistency and quality. Available in various thicknesses and sizes, our plates can be customized to fit specific project needs, from wing spars to fuselage panels. The low density of titanium—about 4.5 g/cm³ compared to steel’s 8 g/cm³—makes it a game-changer for reducing aircraft weight without sacrificing structural integrity. Plus, its natural oxide layer provides stellar corrosion resistance, perfect for harsh environments like high-altitude flights or marine operations.

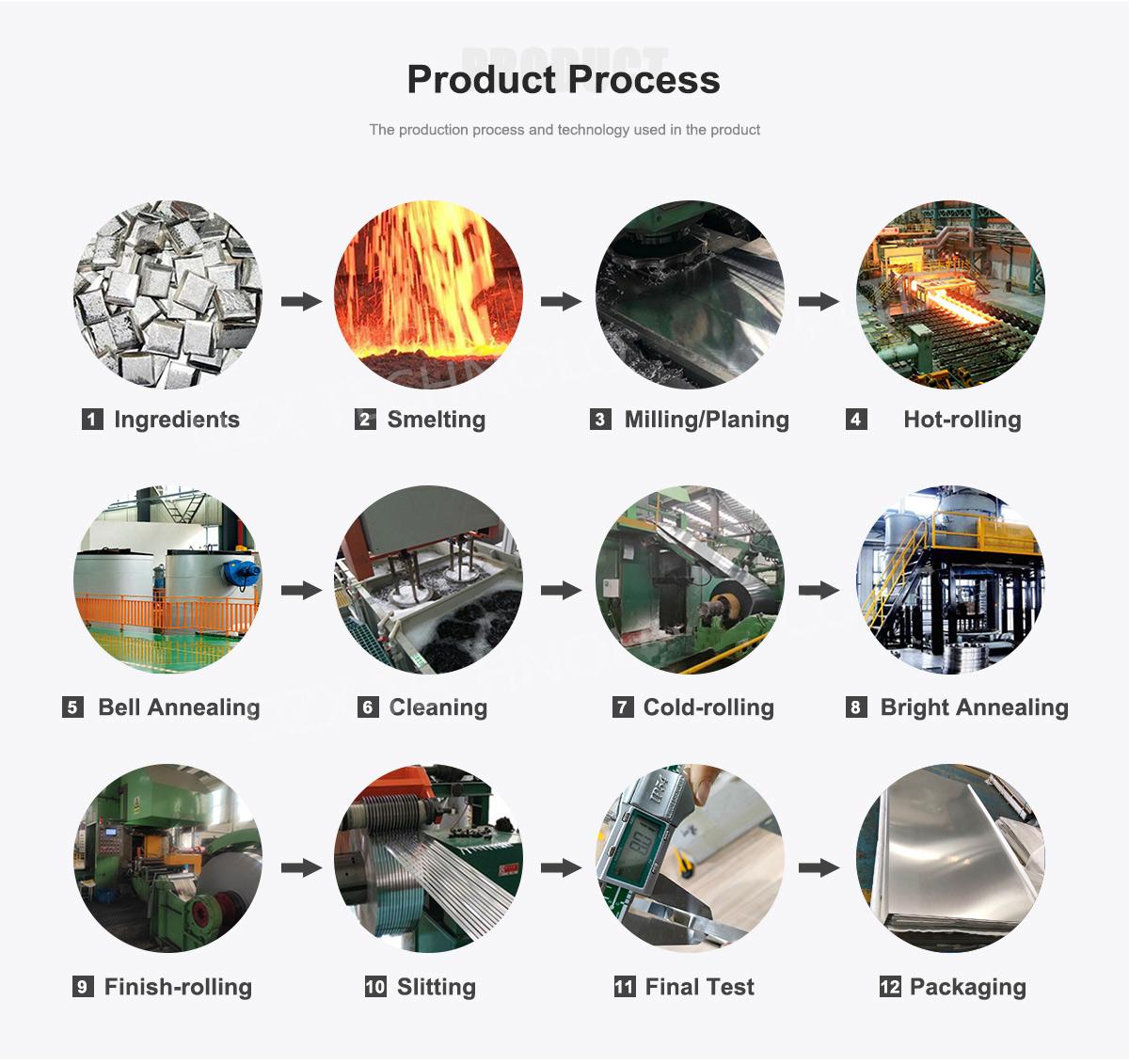

Our manufacturing process leverages advanced techniques, including vacuum arc melting and precision forging, to eliminate defects and enhance mechanical properties. We also embrace additive manufacturing for complex components, minimizing waste and cutting lead times. This commitment to innovation ensures our titanium plates meet the evolving needs of aerospace engineers pushing the boundaries of flight.

For more details, pls directly contact us.

The aerospace industry is soaring, driven by rising demand for fuel-efficient aircraft, advanced military systems, and space exploration. According to market insights, the global aerospace titanium market is projected to hit USD 34.88 billion by 2034, growing at a CAGR of 6.2% from 2024. This growth is fueled by the push for lightweight materials that boost fuel efficiency and reduce emissions, especially in commercial aviation. Military applications, like the F-22 and F-35, also rely heavily on titanium, with some aircraft comprising up to 39% titanium by weight.

Additive manufacturing is transforming the industry, allowing for complex titanium parts with less material waste. This trend aligns with sustainability goals, as titanium’s recyclability supports greener production. However, challenges like high raw material costs and machining difficulties persist. Despite these hurdles, titanium’s unmatched properties make it indispensable, especially as air travel demand surges—global air traffic grew 300% from 1990 to 2019. Emerging markets, like space tourism and unmanned aerial vehicles, are also driving innovation, with titanium plates playing a key role in lightweight, durable designs.

Geopolitical factors, such as supply chain disruptions and titanium’s strategic importance (considered a national security asset in some countries), underscore the need for reliable suppliers. Our company stays ahead by maintaining robust supply chains and investing in R&D to develop next-generation alloys with enhanced strength and temperature resistance.

| Titanium (Ti) | Aluminum (Al) | Vanadium (V) | Tin (Sn) | |

| Ti-6Al-4V | Rest | 5.5%-6.8% | 3.5%-4.5% | |

| Ti-5Al-2.5Sn | Rest | 4.5%-5.5% | 2.0%-3.0% |

Physical Properties

| Density | 4.4-4.5g/cm³ |

| Melting Point | 1660°C |

| Coefficient of Thermal Expansion | 8-10×10⁻⁶/K (20°C-500°C) |

| Thermal Conductivity | 6-22 W/(m·K) (depending on alloy grade) |

| Electrical Resistivity | 0.14-0.17 μΩ·m |

| Tensile Strength | 600-1200 MPa (depending on alloy grade) |

| Yield Strength | 480-1100 MPa |

| Elongation at Break | 10%-25% |

| Hardness | 200-400 HB |

For more details, pls directly contact us.

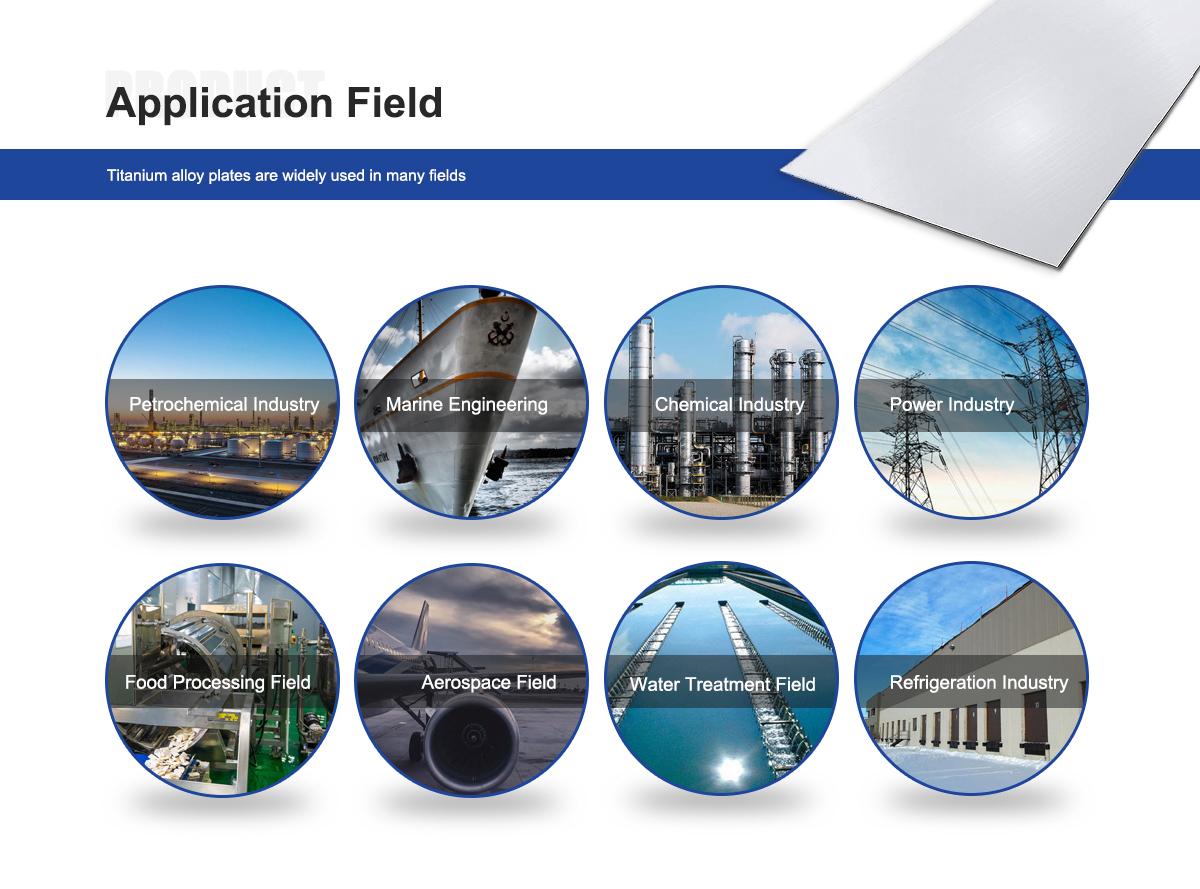

Our titanium plates shine across a range of aerospace applications, making them a go-to choice for engineers. Here’s where they make a difference:

-

Airframes and Structural Components: Used in fuselage panels, wing spars, and bulkheads, our plates provide the strength needed for structural integrity while keeping weight low. For example, the Boeing 787 uses about 15% titanium in its airframe, and our plates are designed to meet similar demands.

-

Jet Engines: Titanium’s ability to withstand temperatures up to 600°C makes it ideal for compressor blades, turbine discs, and casings. Our plates ensure engines run efficiently under extreme heat and stress.

-

Landing Gear: High fatigue strength and corrosion resistance make our plates perfect for landing gear components, which endure cyclic loading and harsh conditions.

-

Spacecraft and Satellites: From fuel tanks to structural supports, our plates offer reliability in the vacuum of space, where radiation and thermal stability are critical. They’ve been used in programs like Apollo and modern space stations.

-

Fasteners and Hydraulic Systems: Our plates are machined into lightweight, corrosion-resistant fasteners and tubing, essential for hydraulic systems in aircraft.

Beyond aerospace, our titanium plates find use in marine environments (thanks to their resistance to seawater corrosion) and medical applications (due to biocompatibility), but aerospace remains their primary domain.

Comparison Parameters Table

|

Parameter |

Our Titanium Plates |

Competitor A |

Competitor B |

|---|---|---|---|

|

Primary Alloy |

Ti-6Al-4V (Grade 5) |

Ti-6Al-4V (Grade 5) |

CP Titanium (Grade 2) |

|

Tensile Strength |

1000 MPa |

950 MPa |

550 MPa |

|

Density |

4.42 g/cm³ |

4.42 g/cm³ |

4.5 g/cm³ |

|

Corrosion Resistance |

Excellent (seawater, high humidity) |

Good |

Excellent |

|

Temperature Resistance |

Up to 600°C |

Up to 550°C |

Up to 400°C |

|

Fatigue Strength |

450–515 MPa |

400–450 MPa |

300–350 MPa |

|

Customization Options |

High (sizes, thicknesses, finishes) |

Limited |

Moderate |

|

Manufacturing Process |

Vacuum arc melting, additive manufacturing |

Traditional forging |

Cold rolling |

|

Standards Compliance |

ASTM B265, AMS 4911 |

ASTM B265 |

ASTM B265 |

|

Recyclability |

Fully recyclable |

Partially recyclable |

Fully recyclable |

Company Advantages

Our company stands out in the aerospace titanium market for several reasons. First, our commitment to quality is unmatched—we use state-of-the-art vacuum arc melting and cold hearth melting to produce defect-free plates that meet the strictest industry standards. Unlike others, we offer extensive customization, allowing engineers to get exactly what they need for complex designs. Our adoption of additive manufacturing sets us apart, enabling faster production of intricate components with minimal waste, which is a big win for both cost and sustainability.

We also prioritize supply chain reliability, ensuring consistent delivery even amidst global disruptions. Our R&D team is constantly innovating, developing high-strength alloys tailored for next-gen aerospace applications, like hypersonic flight and space exploration. With over two decades of experience, we’ve built a reputation for precision and reliability, supplying titanium plates for everything from commercial jets to military aircraft and spacecraft. Our global service centers keep inventory ready, so you’re never left waiting. Plus, our plates are competitively priced, balancing performance with affordability, making us a trusted partner for aerospace manufacturers worldwide.

Why Choose Our Titanium Plates?

Our aerospace-grade titanium plates are more than just materials—they’re a solution to the aerospace industry’s toughest challenges. By reducing weight, enhancing durability, and resisting corrosion, they help aircraft perform better and last longer. Whether you’re building the next commercial jet, a military fighter, or a spacecraft, our plates deliver the reliability and efficiency you need. With cutting-edge manufacturing, a focus on sustainability, and a customer-first approach, we’re here to support your aerospace projects every step of the way.

For more details, pls directly contact us.

About Us:

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications.

For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

FAQs:

-

What makes titanium plates ideal for aerospace?

Their high strength-to-weight ratio, corrosion resistance, and ability to handle extreme temperatures make them perfect for aircraft components. -

Which titanium alloy is most used in your plates?

Ti-6Al-4V (Grade 5) is our primary alloy, offering a great balance of strength, ductility, and fatigue resistance. -

What standards do your titanium plates meet?

Our plates comply with ASTM B265, AMS 4911, and other aerospace-grade specifications for quality and performance. -

Can your titanium plates be customized?

Yes, we offer custom sizes, thicknesses, and finishes to meet specific project requirements. -

How do your plates perform in high-temperature environments?

They maintain structural integrity up to 600°C, ideal for jet engines and high-stress components. -

Are your titanium plates recyclable?

Absolutely, titanium is highly recyclable, supporting sustainable manufacturing without losing its properties. -

What applications use your titanium plates?

They’re used in airframes, jet engines, landing gear, spacecraft, and hydraulic systems, among others. -

How do you ensure quality in your titanium plates?

We use advanced manufacturing like vacuum arc melting and rigorous testing to meet aerospace standards.