In additive manufacturing, the choice of substrate defines the success of each build. Ti6Al4V, also known as Grade 5 titanium, has emerged as the gold standard for high-performance build platforms. At DLX, we’ve engineered our titanium substrates to push the boundaries of precision, reliability, and repeatability in 3D metal printing.

For more details, pls directly contact us.

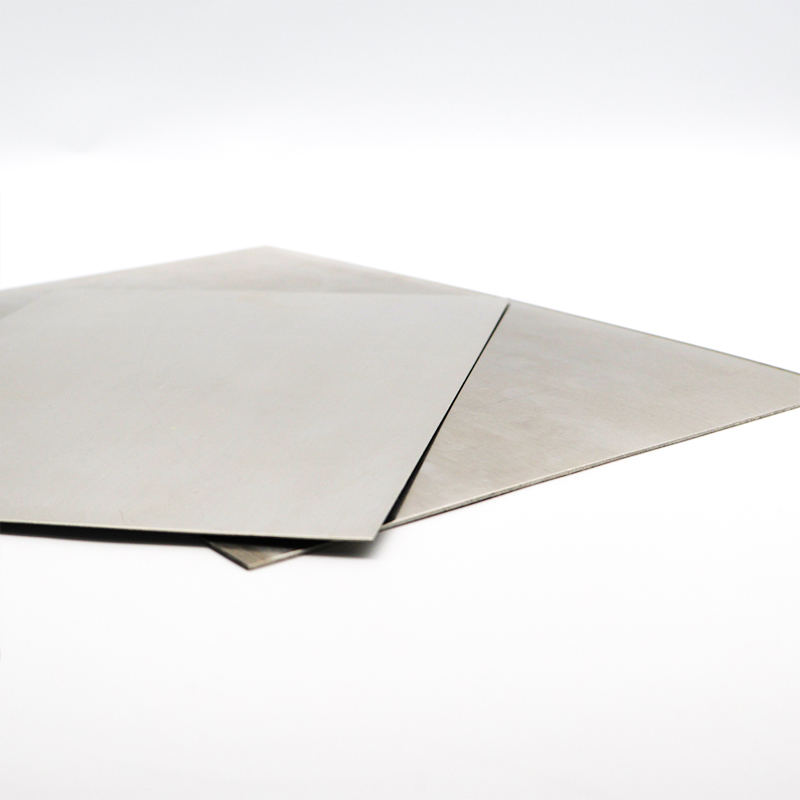

Ti6Al4V is a titanium alloy composed of approximately 90% titanium, 6% aluminum, and 4% vanadium. This unique composition provides an ideal balance of strength and workability. With its high tensile strength and low density, the material ensures the platform remains rigid and stable even during intense thermal cycles. Additionally, its corrosion resistance allows it to endure repeated exposure to oxygen and heat without surface degradation.

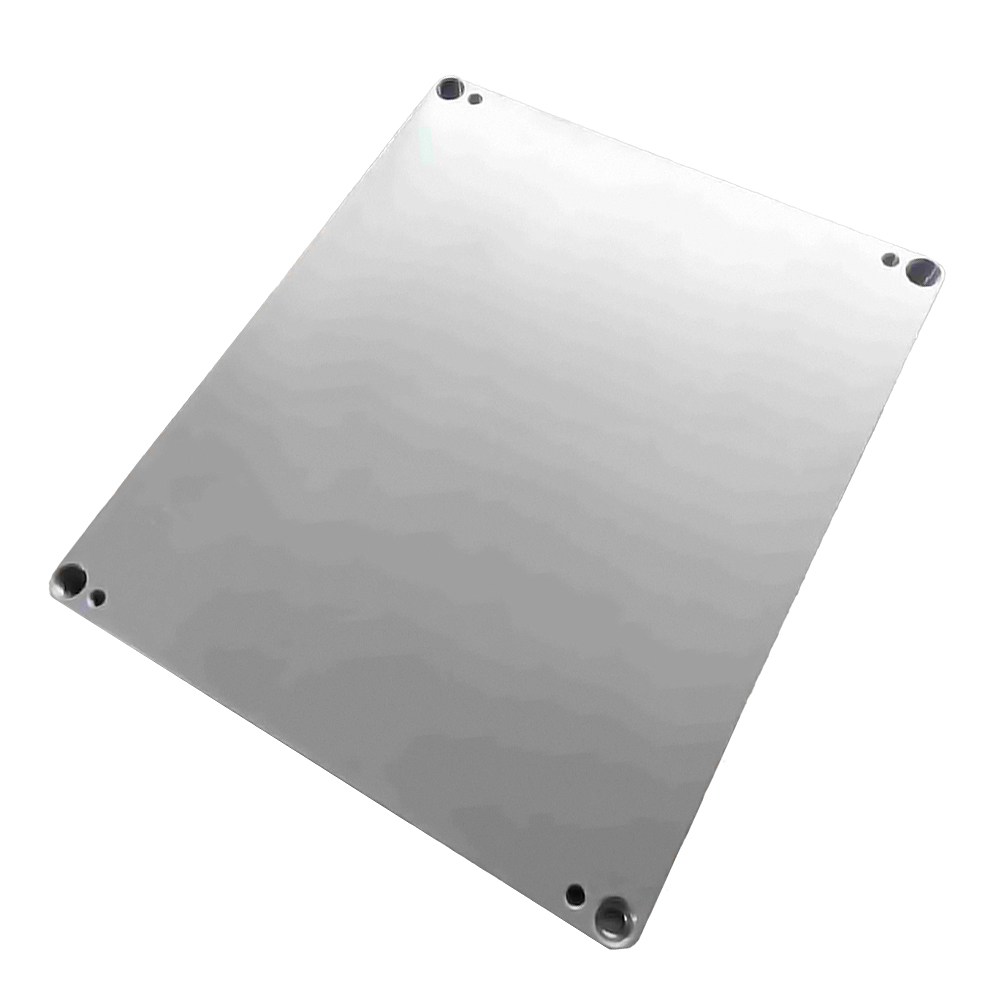

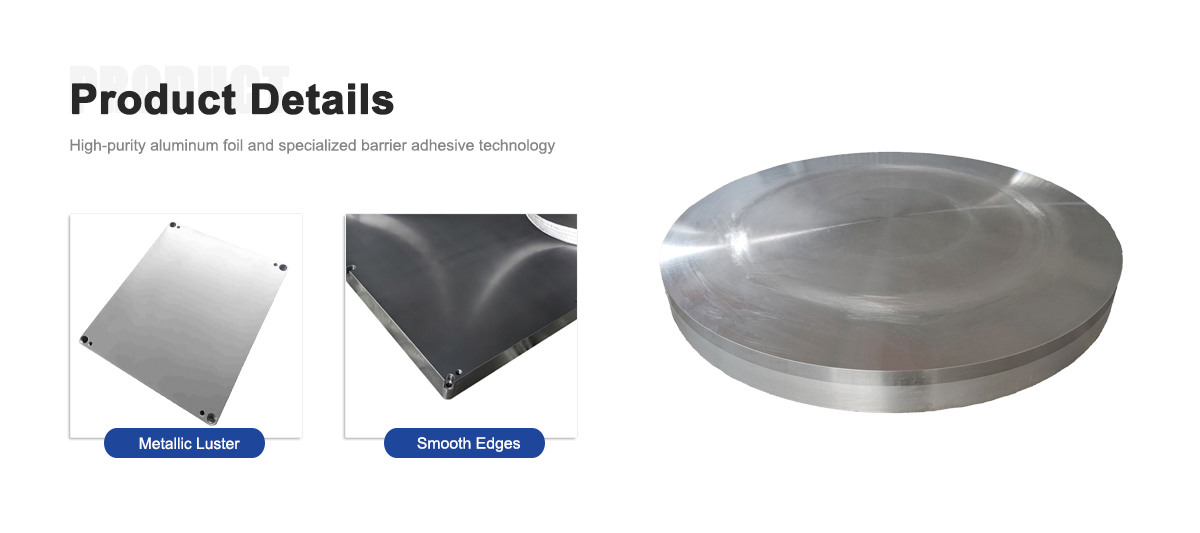

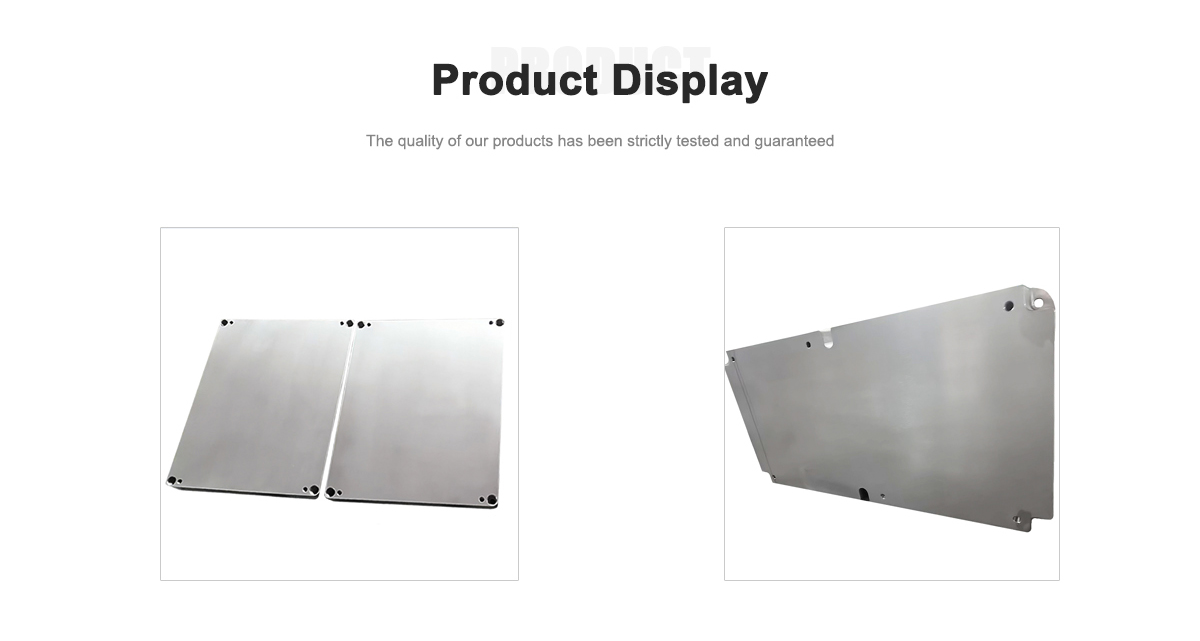

In metal 3D printing, the build platform’s stability directly affects product accuracy. Warping, uneven thermal expansion, or substrate fatigue can lead to layer misalignment and print failure. DLX Ti6Al4V substrates are specifically designed to resist these challenges. We apply advanced machining and controlled heat treatments to achieve exceptional flatness and reduce internal stress — ensuring that each print starts on a solid, reliable foundation.

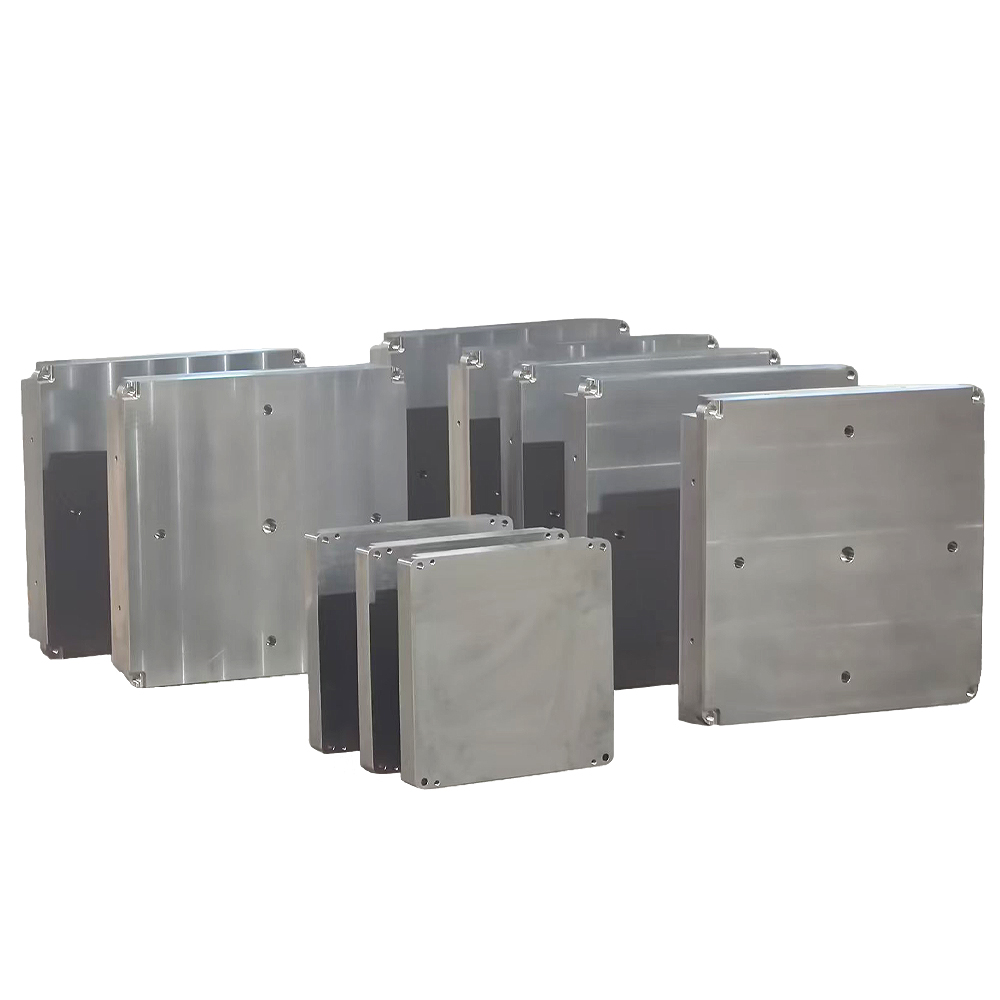

At DLX, we understand that every additive manufacturing system operates differently. That’s why our Ti6Al4V substrates are tailored to match various machine formats and build volumes. Using CNC machining and laser measurement systems, we guarantee uniform surface quality and thickness precision within micrometer-level tolerances.

We also employ double vacuum melting to eliminate impurities, enhancing thermal conductivity and mechanical consistency. This means faster heat distribution, reduced residual stress, and better adhesion between the first layers of printed parts and the substrate.

Technical Comparison Table

| Property | Ti6Al4V (Grade 5) | DLX Ti6Al4V Substrate | Advantage by DLX |

|---|---|---|---|

| Density (g/cm³) | 4.43 | 4.43 (±0.01) | Optimized consistency |

| Tensile Strength (MPa) | 950 | 960–980 | Enhanced via precision heat treatment |

| Yield Strength (MPa) | 880 | 890–910 | Improved stress tolerance |

| Elongation (%) | 14 | 15 | Better flexibility under load |

| Hardness (HB) | 349 | 355 | Controlled grain refinement |

| Melting Point (°C) | 1660 | 1660 | Unchanged, stable under extreme heat |

| Corrosion Resistance | Excellent | Excellent+ | Additional surface oxidation control |

| Flatness Accuracy (mm/m²) | ≤0.1 | ≤0.05 | Ultra-precision machining |

| Build Cycle Life | 200–300 | 400+ | Extended operational durability |

The versatility of Ti6Al4V substrates makes them a key material in several advanced industries.

Aerospace: Used as base plates for lightweight structural components that require high fatigue resistance.

Medical: Ideal for printing orthopedic implants, surgical tools, and dental frameworks due to its biocompatibility.

Automotive: Supports high-performance parts like turbocharger housings and brackets, where strength-to-weight ratio is critical.

Industrial: Used in heat exchangers, turbine components, and tooling applications for superior temperature control.

Industry Trends and Future Outlook

The growth of metal additive manufacturing is driving demand for high-quality build platforms. As 3D printing moves from prototyping to full-scale production, titanium substrates are becoming indispensable. Their combination of strength, thermal resilience, and reusability gives manufacturers a significant edge in both efficiency and reliability.

DLX continues to invest in material science and production automation to meet these demands. By refining our alloy treatments and machining processes, we are creating titanium substrates that can handle higher energy densities and longer print cycles without deformation.

DLX vs. Conventional Manufacturing

Compared to generic metal plates, DLX Ti6Al4V substrates maintain superior flatness and microstructural uniformity. Our proprietary finishing process minimizes surface oxidation and provides optimal adhesion for the first layers of powder. This not only reduces print defects but also extends the platform’s usable life — a clear cost advantage for high-volume users.

While some companies treat substrates as consumables, DLX designs them as long-term assets. Our titanium plates can endure hundreds of printing cycles, which reduces downtime and replacement frequency.

Every DLX titanium substrate comes with full traceability, mechanical certification, and dimensional inspection reports. We partner with clients to fine-tune substrate design according to their specific printer setup, ensuring maximum efficiency. Our goal is to help customers produce consistent, high-quality prints — every single time.

The Ti6Al4V Titanium Substrate (Grade 5) by DLX is more than just a printing platform — it’s the foundation for precision and repeatability in modern additive manufacturing. With superior flatness, exceptional strength, and long operational life, it supports advanced 3D printing technologies used across critical industries worldwide.

As the manufacturing world continues to evolve, DLX remains at the forefront of titanium substrate innovation — providing the reliability and performance that define the next generation of metal 3D printing.

About Us:

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications.

For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

FAQs:

1. What is Ti6Al4V Titanium Substrate (Grade 5)?

Ti6Al4V, also known as Grade 5 titanium, is an alpha-beta titanium alloy used as a build platform or base plate for additive manufacturing. It combines high strength, low density, and excellent corrosion resistance, making it one of the most reliable materials for 3D printing applications.

2. Why is Ti6Al4V the preferred alloy for additive manufacturing platforms?

Because it offers an exceptional balance of strength, thermal stability, and weldability. These properties ensure that the build platform maintains flatness and precision during repeated heating and cooling cycles in metal 3D printing.

3. What are the main properties of Ti6Al4V alloy?

Ti6Al4V features a tensile strength of around 950 MPa, a melting point above 1600°C, and excellent resistance to oxidation and chemical corrosion. It’s also biocompatible, making it suitable for medical and aerospace manufacturing.

4. What makes DLX titanium substrates different?

DLX substrates are manufactured using vacuum melting, precision machining, and heat treatment to achieve uniform grain structure, minimal residual stress, and exceptional surface flatness — key factors that improve print quality and extend substrate lifespan.

5. Which 3D printing technologies are compatible with DLX Ti6Al4V substrates?

They are compatible with most metal additive manufacturing systems, including Selective Laser Melting (SLM), Direct Metal Laser Sintering (DMLS), and Electron Beam Melting (EBM).

6. In which industries are Ti6Al4V substrates most commonly used?

Ti6Al4V substrates are widely used in aerospace, medical implants, automotive, and high-end industrial components, where precision, strength, and reliability are critical.

7. Can DLX customize dimensions and surface finishes?

Yes. DLX offers customized sizes, surface roughness levels, and edge machining based on printer models and customer requirements. Polished, ground, and treated surfaces are all available.

8. How long can a titanium substrate last in production use?

With proper maintenance, DLX Ti6Al4V substrates can last hundreds of build cycles without warping or surface degradation, thanks to their superior fatigue and heat resistance.