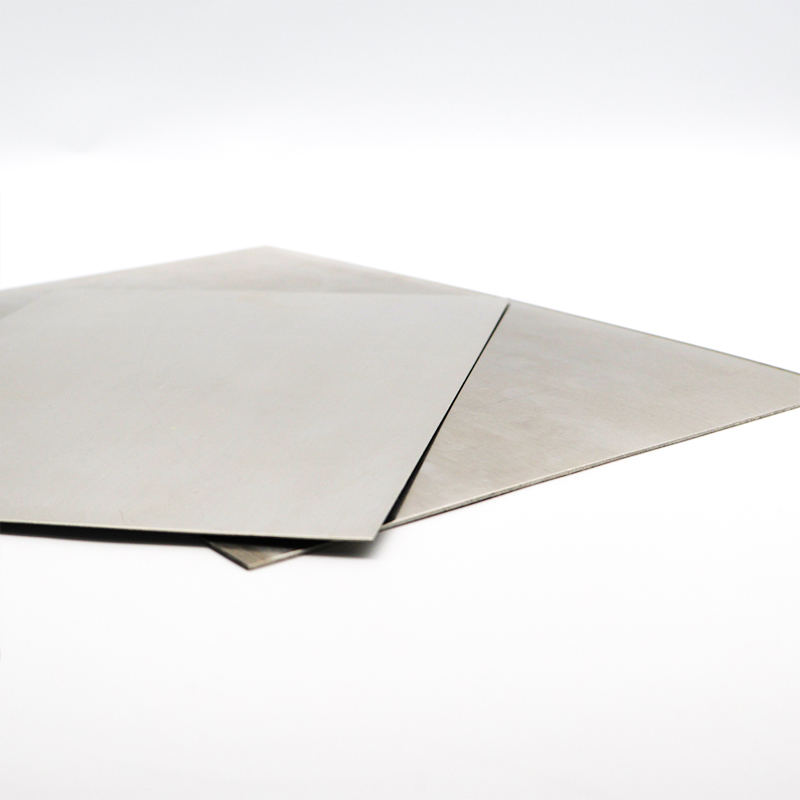

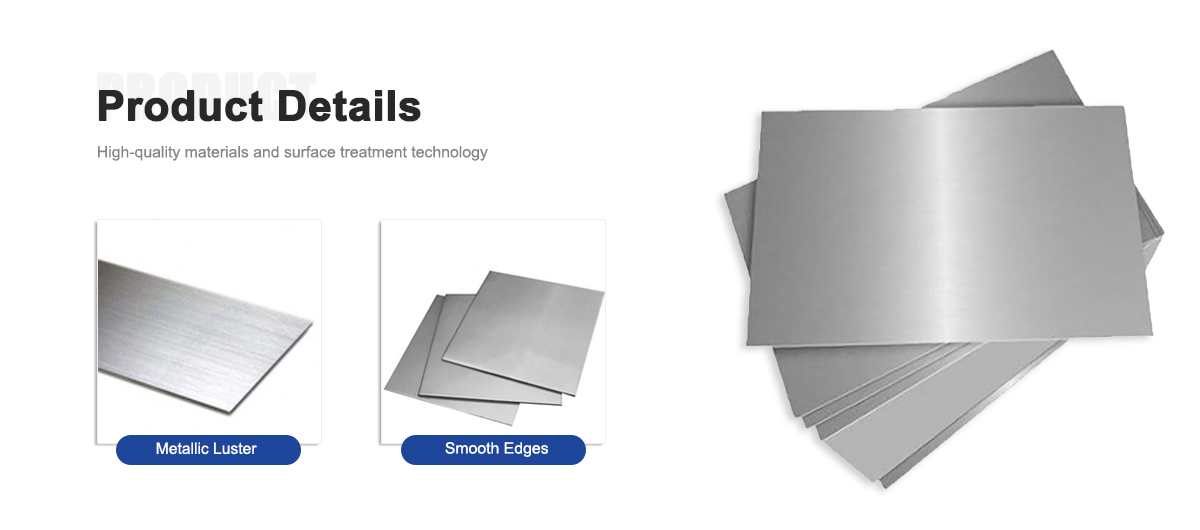

Our Grade 7 Titanium Plate s are engineered for applications demanding top-tier corrosion resistance in the harshest environments. Made from a titanium alloy with 0.12–0.25% palladium, Grade 7 combines excellent corrosion resistance with a tensile strength of up to 345 MPa. With a density of 4.5 g/cm³—about half that of steel—these plates are lightweight yet durable, perfect for industries like chemical processing, marine, and desalination where corrosion is a constant challenge.

Certified to ASTM B265 standards, our plates are available in thicknesses from 0.5 mm to 100 mm and can be customized to precise specifications using advanced CNC machining and laser cutting. We use vacuum arc melting and precision rolling to produce defect-free plates with consistent mechanical properties. Grade 7’s palladium addition enhances resistance to reducing acids, chlorides, and crevice corrosion, making it ideal for aggressive conditions like hot brine or acidic solutions.

We prioritize sustainability and cost-efficiency, using recyclable titanium and optimized production to minimize waste. Their lightweight design reduces structural loads, and their durability cuts maintenance costs. For industries needing materials that stand up to corrosion without compromising performance, our Grade 7 titanium plates are a stellar choice.

For more details, pls directly contact us.

The demand for corrosion-resistant materials is surging across industries like chemical processing, marine, and energy, driven by the need for durable equipment in harsh environments. The global titanium market, valued at USD 20.4 billion in 2024, is projected to grow at a CAGR of 5.4% through 2032, with Grade 7 titanium standing out for its superior corrosion resistance. Its ability to withstand reducing acids and chlorides makes it a go-to for applications where other materials fail.

Key trends include the push for sustainability, with titanium’s recyclability aligning with eco-friendly manufacturing goals—global industries are under pressure to reduce environmental impact, and titanium fits the bill. The rise of desalination plants, driven by water scarcity affecting 50% of the world’s population by 2030, is boosting demand for corrosion-resistant materials. Industry 4.0 technologies, like IoT and predictive maintenance, are enhancing equipment efficiency, where Grade 7’s durability ensures long-term reliability. Growth in offshore energy and green hydrogen production further drives titanium use in corrosive environments.

Challenges include titanium’s higher upfront cost and machining complexity compared to stainless steel or nickel alloys. However, its longevity and low maintenance make it a cost-effective choice over time. Supply chain stability for palladium-enhanced alloys is critical, and our robust sourcing ensures consistent availability. The expansion of renewable energy and water treatment infrastructure is creating new opportunities for Grade 7 titanium in high-corrosion applications.

| Titanium (Ti) | Aluminum (Al) | Vanadium (V) | Tin (Sn) | |

| Ti-6Al-4V | Rest | 5.5%-6.8% | 3.5%-4.5% | |

| Ti-5Al-2.5Sn | Rest | 4.5%-5.5% | 2.0%-3.0% |

Physical Properties

| Density | 4.4-4.5g/cm³ |

| Melting Point | 1660°C |

| Coefficient of Thermal Expansion | 8-10×10⁻⁶/K (20°C-500°C) |

| Thermal Conductivity | 6-22 W/(m·K) (depending on alloy grade) |

| Electrical Resistivity | 0.14-0.17 μΩ·m |

| Tensile Strength | 600-1200 MPa (depending on alloy grade) |

| Yield Strength | 480-1100 MPa |

| Elongation at Break | 10%-25% |

| Hardness | 200-400 HB |

For more details, pls directly contact us.

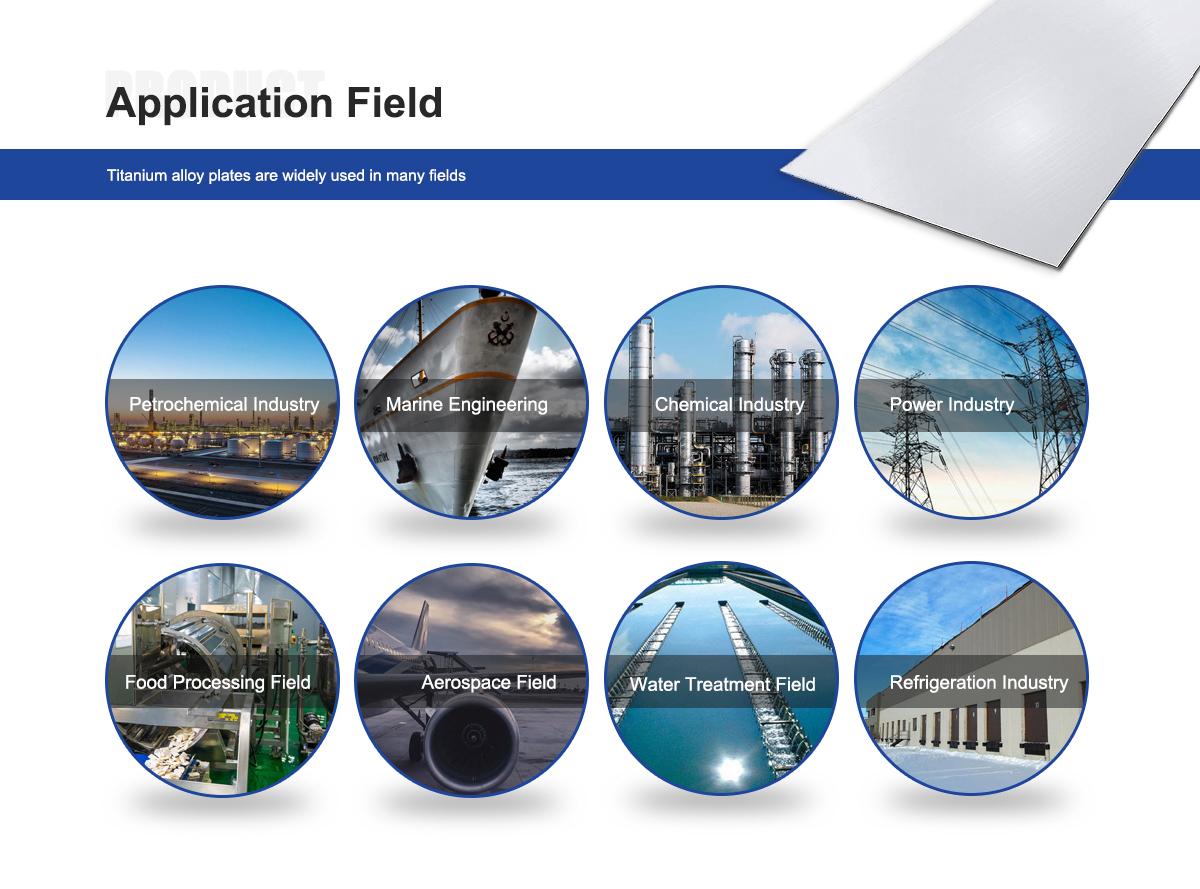

Our Grade 7 titanium plates are versatile, excelling in industries requiring superior corrosion resistance:

Chemical Processing: Used in reactors, tanks, and piping, our plates resist reducing acids and chlorides for safe, reliable operation.

Desalination Plants: They’re ideal for evaporators and heat exchangers, handling high-salinity brine and aggressive cleaning agents.

Marine Equipment: Our plates are used in ship fittings, propellers, and offshore platforms, resisting seawater and salt spray.

Oil and Gas: They support pipelines and valves in sour gas environments, preventing corrosion under high pressure.

Green Hydrogen Production: Used in electrolyzers and storage systems, our plates withstand corrosive electrolytes and high temperatures.

Pharmaceutical Manufacturing: They’re crafted into equipment for drug production, resisting corrosion from cleaning agents and acids.

Heat Exchangers: Our plates excel in plate-and-frame or shell-and-tube designs, handling corrosive fluids in industrial systems.

Pulp and Paper Industry: They resist bleaching chemicals and high temperatures in processing equipment, extending service life.

Comparison Parameters Table

Parameter | Our Titanium Plates | Competitor A | Competitor B |

|---|---|---|---|

Material | Grade 7 (Ti-0.12-0.25Pd) | Grade 2 Titanium | Stainless Steel (316L) |

Tensile Strength | 345 MPa | 550 MPa | 580 MPa |

Corrosion Resistance | Superior (acids, chlorides, crevice corrosion) | Excellent (general corrosion) | Moderate (prone to pitting) |

Density | 4.5 g/cm³ | 4.5 g/cm³ | 8.0 g/cm³ |

Temperature Resistance | Up to 300°C | Up to 400°C | Up to 800°C |

Customization Options | Extensive (sizes, thicknesses, finishes) | Limited | Moderate |

Manufacturing Process | Vacuum arc melting, CNC machining, laser cutting | Basic rolling | Standard fabrication |

Standards Compliance | ASTM B265 | ASTM B265 | ASTM A240 |

Company Advantages

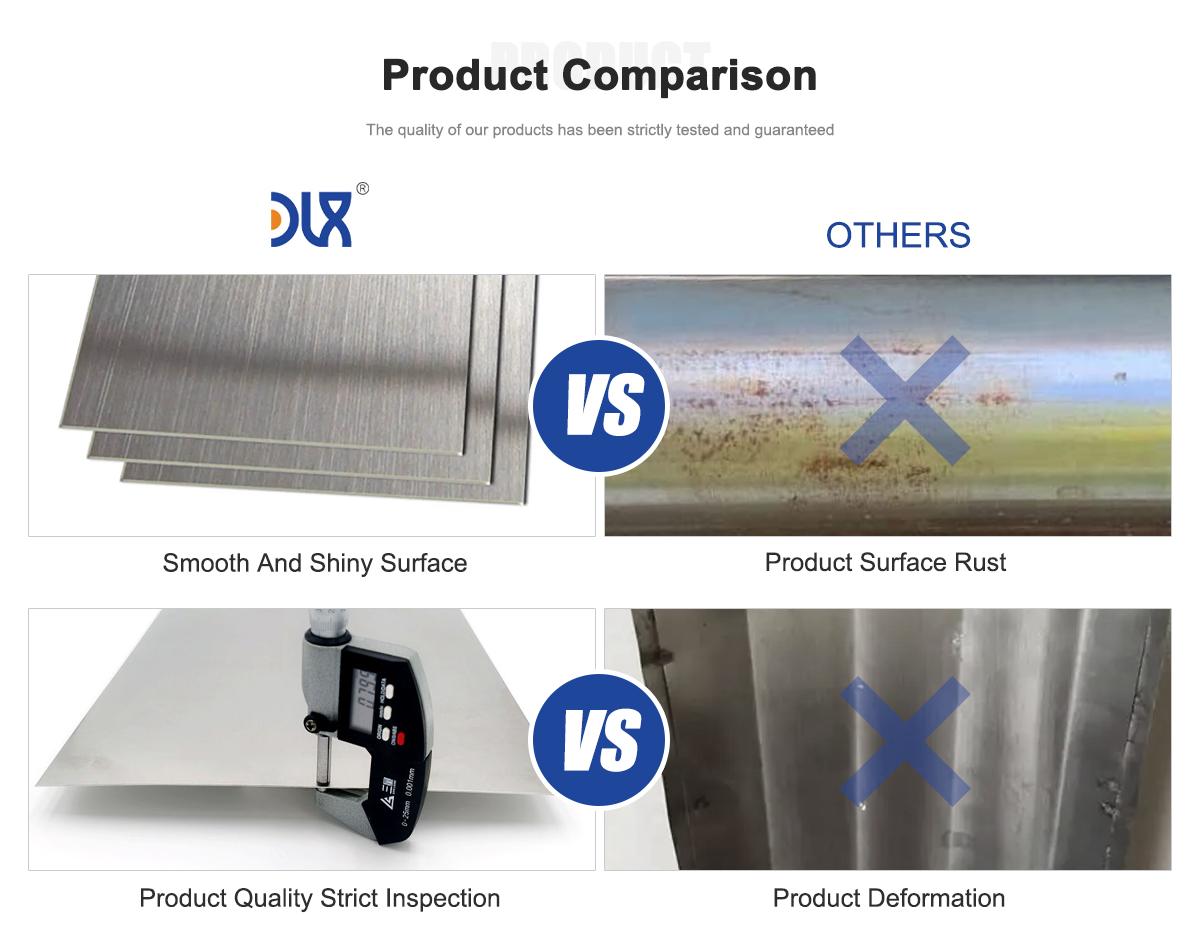

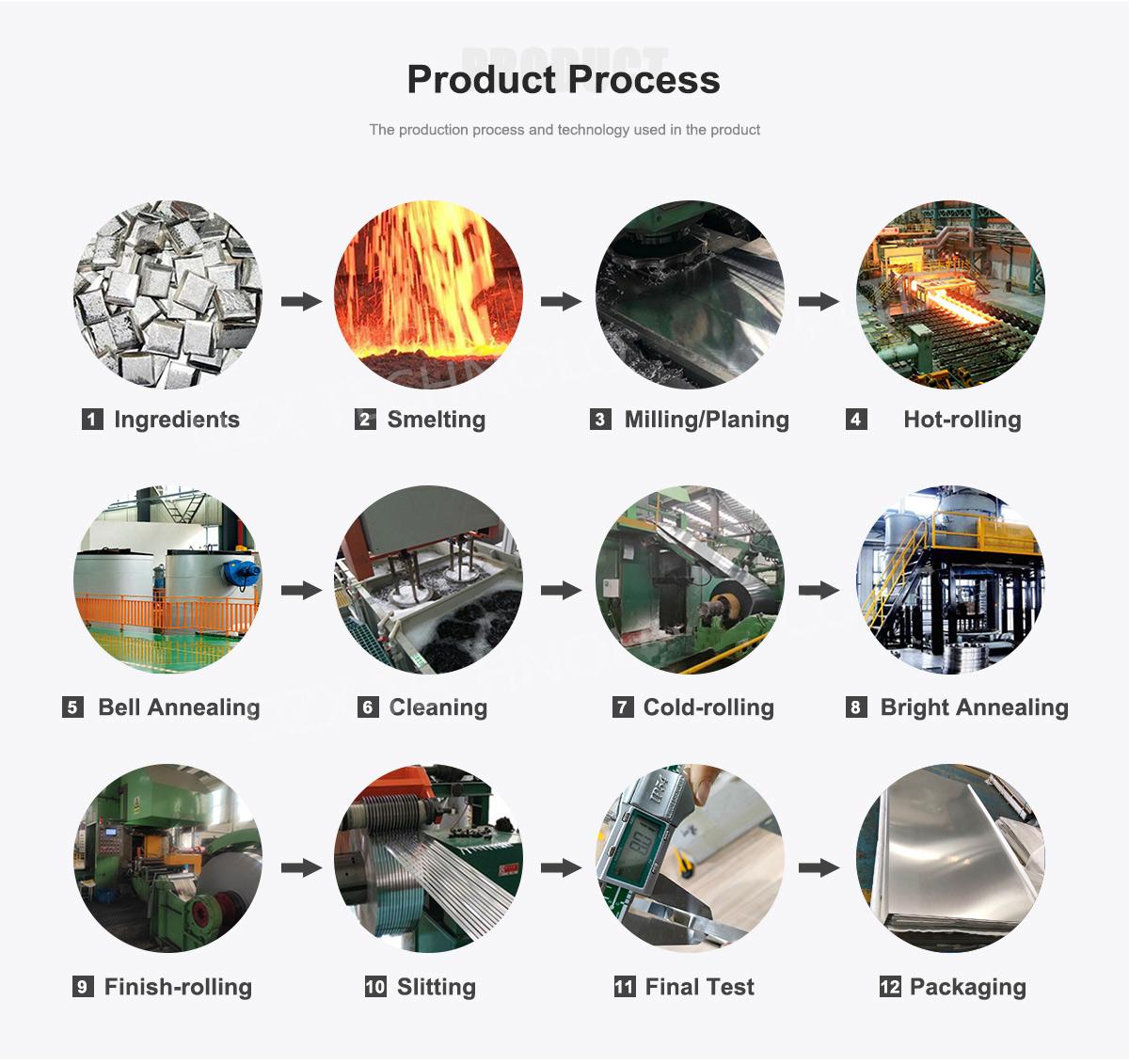

Our Grade 7 titanium plates are a standout for applications demanding superior corrosion resistance. We use state-of-the-art vacuum arc melting, precision rolling, and CNC machining to produce plates with exceptional quality and performance. Unlike others, we offer full customization, tailoring sizes, thicknesses, and finishes to match your exact needs, from chemical reactors to desalination evaporators, ensuring seamless integration and reliability.

Our supply chain is rock-solid, securing high-quality palladium-enhanced titanium even in volatile markets, so your projects stay on schedule. We’re pushing the envelope with additive manufacturing, crafting complex parts with minimal waste, which keeps costs down and supports sustainability. Our plates are fully recyclable, and our production minimizes environmental impact, aligning with green industry trends like clean energy and water treatment.

With decades of expertise, we deliver plates that meet the strictest industry standards. Our R&D team is constantly innovating, developing processes for next-gen applications like green hydrogen and offshore systems. Our global network ensures fast inventory access, and our plates’ durability means less maintenance and longer equipment life, saving you money. We’re the trusted partner for industries needing corrosion-resistant, high-performance materials.

Why Choose Our Titanium Plates?

Our Grade 7 titanium plates are built to power applications in corrosive environments, delivering unmatched resistance to acids, chlorides, and saltwater. From chemical plants to offshore platforms, they ensure durability and reliability with minimal maintenance. With cutting-edge manufacturing, a focus on sustainability, and a commitment to your success, we’re here to make your projects thrive in the toughest conditions.

For more details, pls directly contact us.

About Us:

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications.

For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

FAQs:

Why use Grade 7 titanium for corrosion resistance?

Its palladium alloy offers superior resistance to reducing acids, chlorides, and crevice corrosion.What standards do your plates meet?

They comply with ASTM B265 for quality and reliability.Can your plates be customized?

Yes, we tailor sizes, thicknesses, and finishes to fit specific designs.How do your plates perform in corrosive environments?

They excel against acids, chlorides, and saltwater, even in high-temperature conditions.Are your titanium plates recyclable?

Absolutely, titanium is fully recyclable, supporting sustainable manufacturing.What applications use your plates?

Chemical processing, desalination, marine, oil and gas, hydrogen production, pharmaceuticals, heat exchangers, and pulp and paper.How do you ensure plate quality?

We use vacuum arc melting, precision rolling, CNC machining, and rigorous testing for defect-free plates.Do your plates reduce maintenance costs?

Yes, their durability and corrosion resistance minimize downtime and repairs.