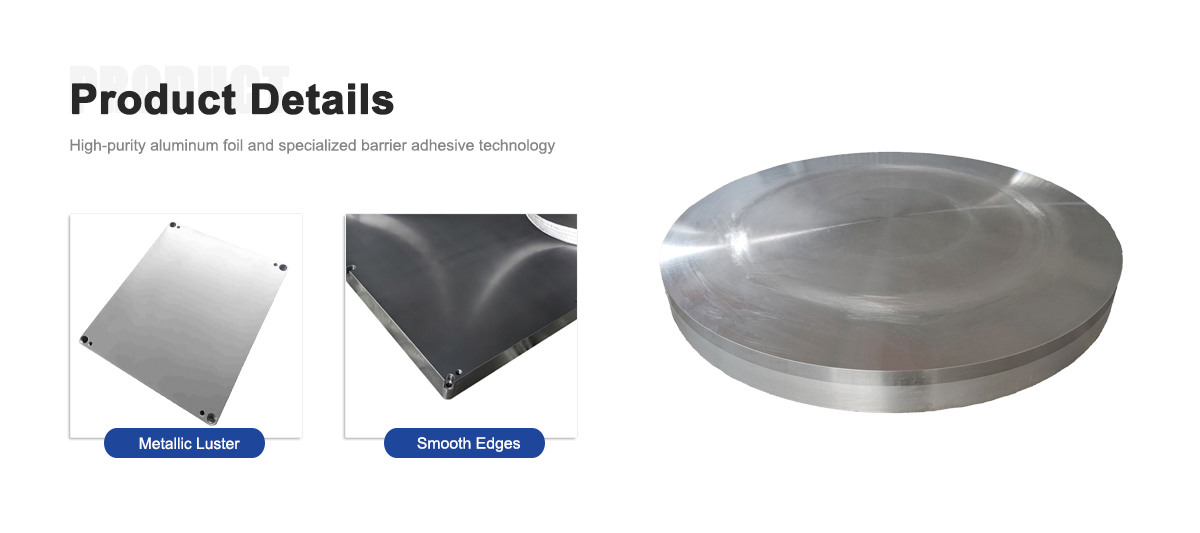

When it comes to high-performance 3D printing, the substrate material can make or break your results. At DLX, we focus on delivering Titanium Alloy substrates that meet the rigorous demands of modern additive manufacturing. Titanium alloys, especially Ti6Al4V and Ti-6Al-4V ELI, have become industry benchmarks due to their unmatched combination of strength, lightness, and corrosion resistance.

For more details, pls directly contact us.

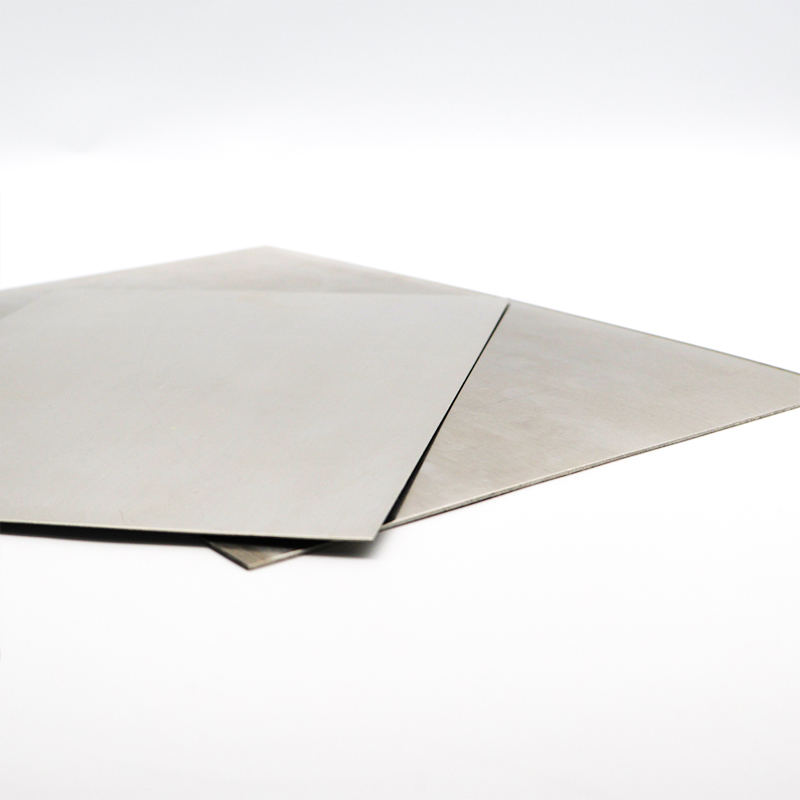

A 3D printing substrate isn’t just a flat piece of metal; it’s the foundation for precision, stability, and long-term performance. Titanium’s low density and high tensile strength ensure that even complex 3D printed parts adhere perfectly and maintain dimensional accuracy. This is crucial in sectors like aerospace and medical devices, where tolerance is non-negotiable.

DLX substrates are engineered to reduce residual stress and prevent warping, which can be common in high-temperature metal printing. By controlling the alloy composition and employing advanced heat treatment techniques, our substrates provide a flat, stable surface ready for repeated printing cycles.

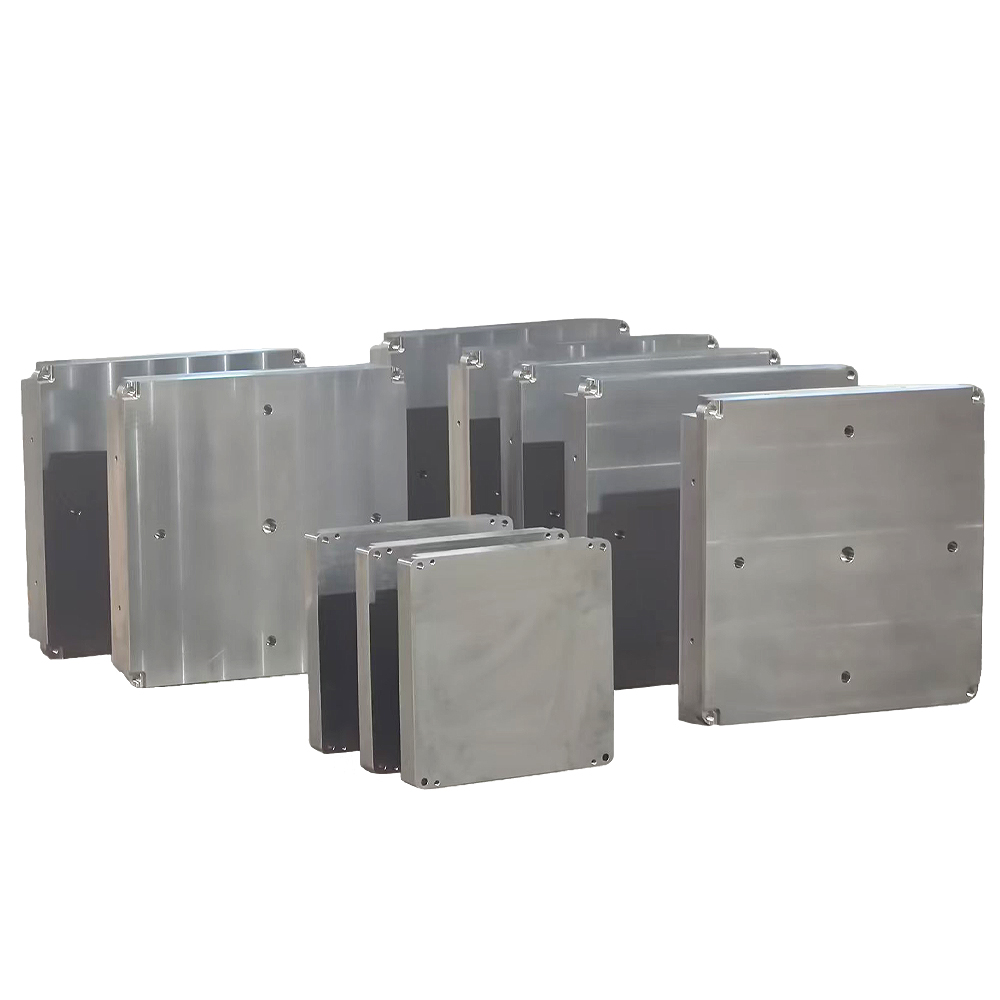

We also understand that not every printer is the same. That’s why we offer fully customizable substrate dimensions. Whether it’s a small-scale dental printer or a large industrial SLM system, DLX can deliver substrates that integrate seamlessly into your production line.

Titanium Alloy Substrate Comparison Table

| Parameter | Ti6Al4V (Grade 5) | Ti-6Al-4V ELI (Grade 23) | DLX Substrate Advantage |

|---|---|---|---|

| Density (g/cm³) | 4.43 | 4.41 | Optimized for lightweight stability |

| Tensile Strength (MPa) | 950 | 860 | Consistent strength across all batches |

| Yield Strength (MPa) | 880 | 795 | Enhanced surface integrity |

| Elongation (%) | 14 | 10 | Uniform deformation resistance |

| Corrosion Resistance | Excellent | Excellent | Superior oxidation control |

| Temperature Stability | 600°C | 600°C | Maintains flatness under heat |

| Surface Finish | Polished or machined | Polished or machined | Customizable for printer compatibility |

| Industry Standards | ASTM B348, ISO 5832-3 | ASTM B348, ISO 5832-3 | Fully certified with traceability |

Titanium alloy substrates are increasingly replacing steel and aluminum bases due to their superior thermal stability and corrosion resistance. In aerospace, lightweight yet robust substrates reduce component distortion during printing, while in medical 3D printing, the biocompatibility of titanium ensures safety and performance for surgical implants. Automotive and industrial machinery sectors also rely on these substrates for high-strength, heat-resistant parts.

Industry Trends Driving Adoption

The trend toward high-performance additive manufacturing is accelerating, with more companies embracing titanium alloys for critical applications. This growth is fueled by the demand for lighter, stronger, and more durable components. DLX stays ahead by continuously refining its titanium substrate offerings to match these evolving needs.

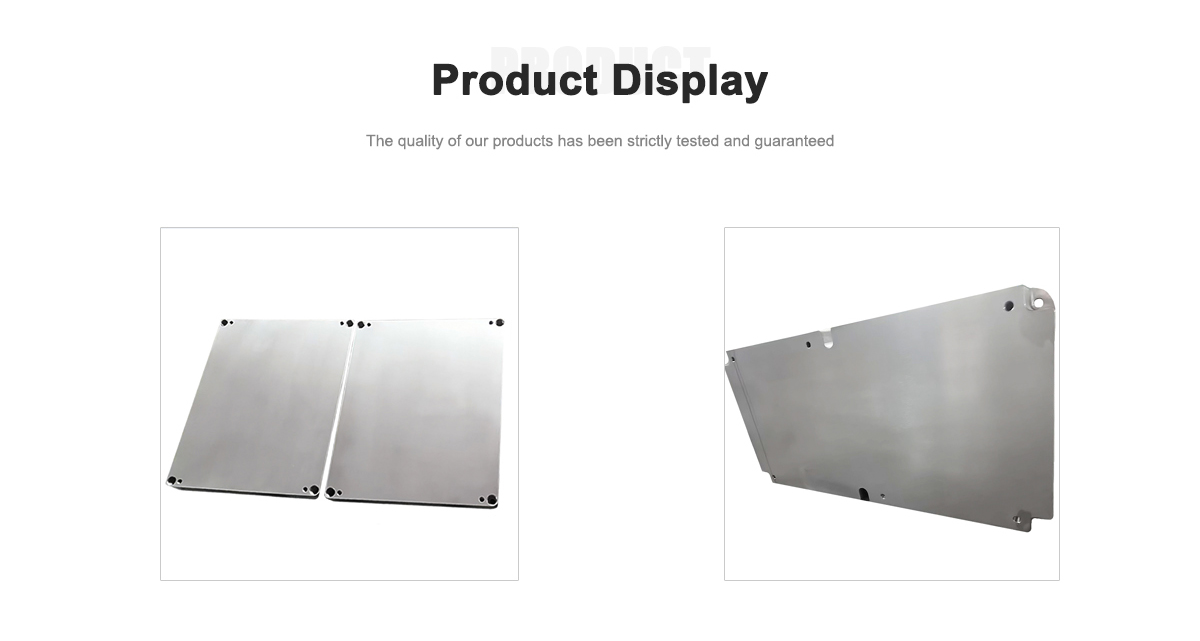

While many manufacturers offer titanium substrates, DLX distinguishes itself through precision engineering, rigorous testing, and a customer-centric approach. Each substrate undergoes quality checks for flatness, composition, and thermal stability, ensuring every batch meets industry standards. This attention to detail translates to fewer print failures, higher efficiency, and ultimately, a lower total cost of ownership for our clients.

DLX titanium substrates are compatible with SLM, DMLS, and other powder-bed fusion methods. The substrates’ high-temperature resistance and stable surface ensure excellent adhesion of printed layers and minimal warping. This compatibility makes DLX the go-to choice for industries that cannot compromise on quality.

As 3D printing evolves, the demand for superior substrate materials will only grow. DLX is committed to innovation, leveraging cutting-edge metallurgical processes to create substrates that push the boundaries of what additive manufacturing can achieve. Our focus on titanium alloys ensures that clients receive products that are durable, reliable, and ready for the most demanding applications.

In summary, DLX titanium alloy substrates provide unmatched strength, stability, and corrosion resistance. They are engineered for precision, compatible with multiple 3D printing technologies, and optimized for industries requiring high-performance materials. Choosing DLX means choosing a substrate that delivers consistent, reliable results while supporting the growth of additive manufacturing technology.

About Us:

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications.

For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

FAQs:

1. What is a Titanium Alloy Substrate for 3D printing?

A titanium alloy substrate is a base material made from high-strength titanium alloys designed to support 3D printing processes. It offers excellent corrosion resistance, stability at high temperatures, and superior mechanical properties.

2. Which titanium alloy grades are commonly used for 3D printing substrates?

Ti6Al4V (Grade 5) and Ti-6Al-4V ELI (Grade 23) are the most widely used. These alloys combine high strength, low density, and excellent biocompatibility, making them ideal for aerospace, medical, and industrial applications.

3. Can these substrates handle high-temperature printing?

Yes, titanium alloy substrates have high melting points and maintain dimensional stability at elevated temperatures, making them perfect for metal additive manufacturing methods like SLM and DMLS.

4. How does DLX ensure the quality of its titanium alloy substrates?

DLX uses precise alloying, strict heat treatment, and advanced surface finishing processes to provide substrates with uniform density, flatness, and low residual stress, ensuring consistent 3D printing performance.

5. What industries commonly use titanium alloy 3D printing substrates?

Aerospace, medical, automotive, and industrial machinery sectors rely heavily on titanium substrates due to their strength-to-weight ratio, corrosion resistance, and reliability under extreme conditions.

6. Can DLX customize substrate dimensions for different 3D printers?

Absolutely. DLX offers tailored substrate sizes and thicknesses to match a wide range of 3D printing systems, including powder bed fusion, laser melting, and electron beam additive manufacturing setups.

7. How does titanium compare to other metals for 3D printing substrates?

Titanium stands out due to its combination of high strength, low density, and corrosion resistance. Unlike steel or aluminum, titanium substrates provide superior thermal stability and longevity for repeated printing cycles.

8. Is DLX titanium alloy substrate compatible with post-processing techniques?

Yes, substrates from DLX are designed to endure machining, polishing, and coating processes, allowing for versatile post-processing without compromising structural integrity.