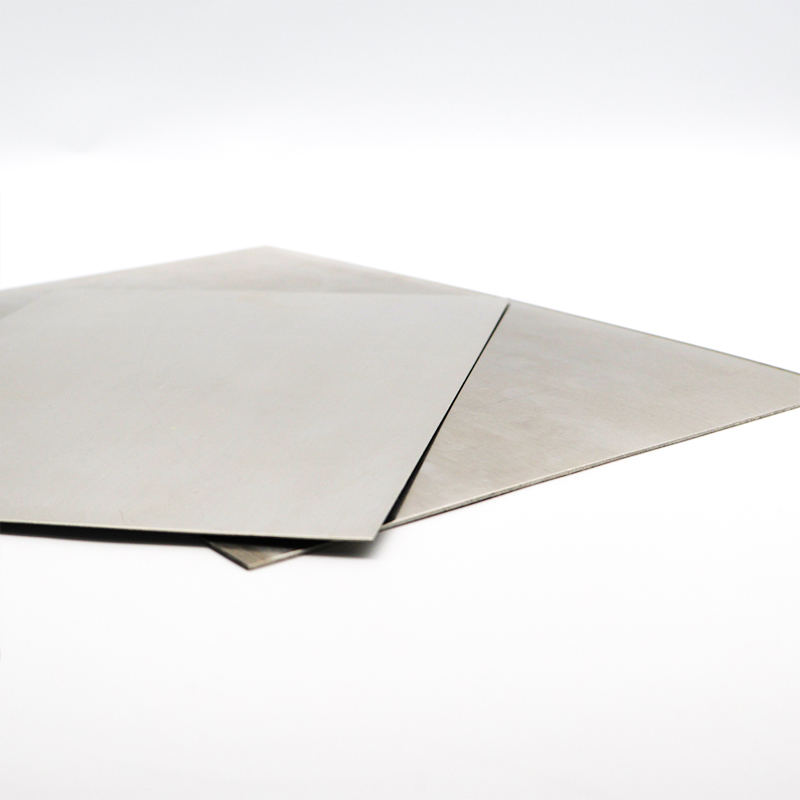

In the evolving field of metal additive manufacturing, the demand for high-performance build substrates is stronger than ever. Among all materials available, Ti-6Al-4V ELI (Grade 23) stands out for its remarkable combination of purity, toughness, and biocompatibility. At DLX, we produce titanium substrates specifically engineered for aerospace and medical 3D printing — two sectors where precision and reliability are absolutely non-negotiable.

For more details, pls directly contact us.

Ti-6Al-4V ELI, short for “Extra Low Interstitial,” is a variant of the widely used Grade 5 titanium alloy. The reduction of interstitial elements such as oxygen, nitrogen, and iron makes the alloy cleaner and more ductile, which translates into higher impact resistance and longer fatigue life. This material characteristic is critical for both flight components and medical implants, where microstructural consistency directly affects performance and safety.

| Property / Specification | Ti-6Al-4V (Grade 5) | Ti-6Al-4V ELI (Grade 23) | DLX Grade 23 Titanium Substrate | DLX Advantage |

|---|---|---|---|---|

| Oxygen Content (%) | ≤ 0.20 | ≤ 0.13 | ≤ 0.12 | Ultra-low impurities |

| Tensile Strength (MPa) | 950 | 910 | 920–940 | Stable and consistent strength |

| Yield Strength (MPa) | 880 | 860 | 880+ | Enhanced toughness |

| Elongation (%) | 14 | 15–16 | 16+ | Greater ductility |

| Density (g/cm³) | 4.43 | 4.43 | 4.43 | Lightweight with strong rigidity |

| Corrosion Resistance | Excellent | Excellent+ | Superior surface passivation | |

| Biocompatibility | High | Very High | Optimized for medical use | |

| Build Cycle Life | 300+ | 400+ | 450+ | Extended durability and reusability |

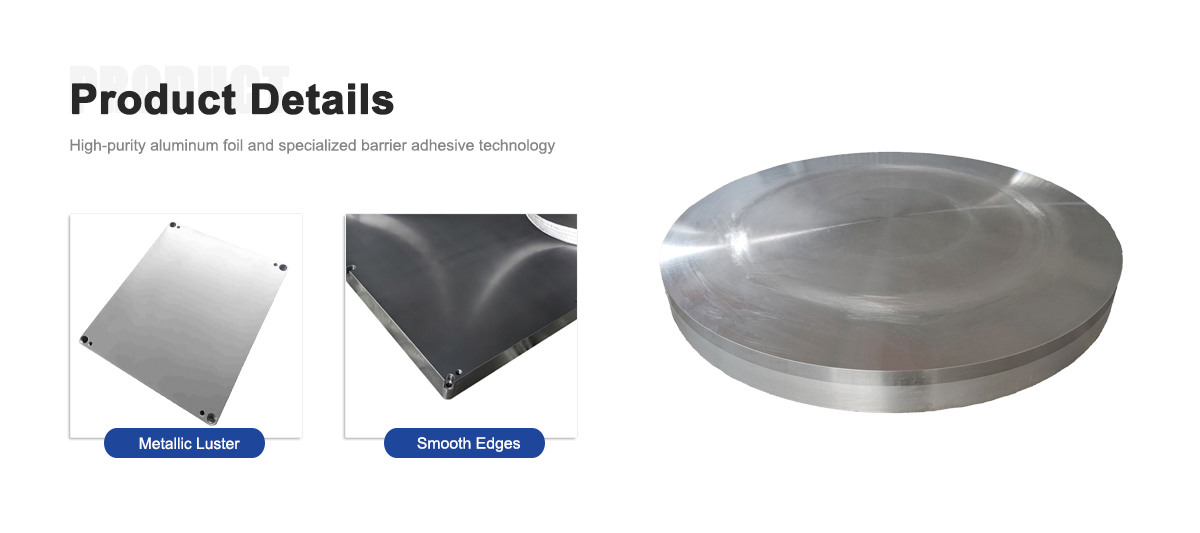

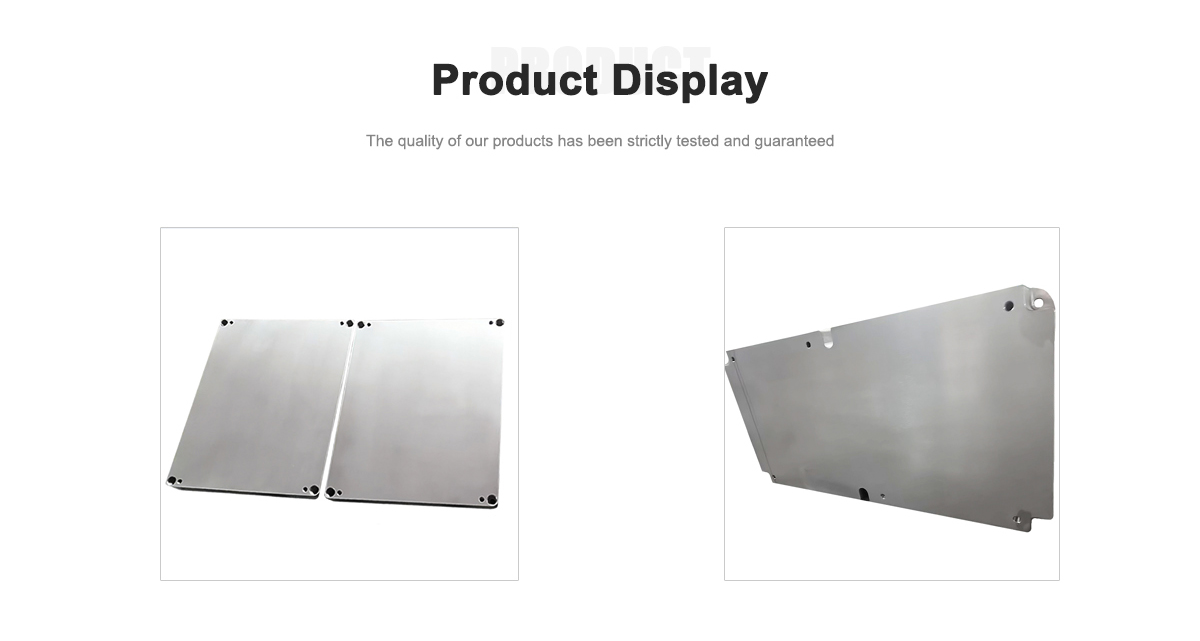

DLX has spent years refining titanium substrate production for metal additive manufacturing. Our Ti-6Al-4V ELI substrates are produced using double vacuum melting and controlled heat treatments to ensure low residual stress and precise flatness. These treatments allow the plate to endure repetitive thermal cycles typical in SLM and DMLS systems without distortion or cracking.

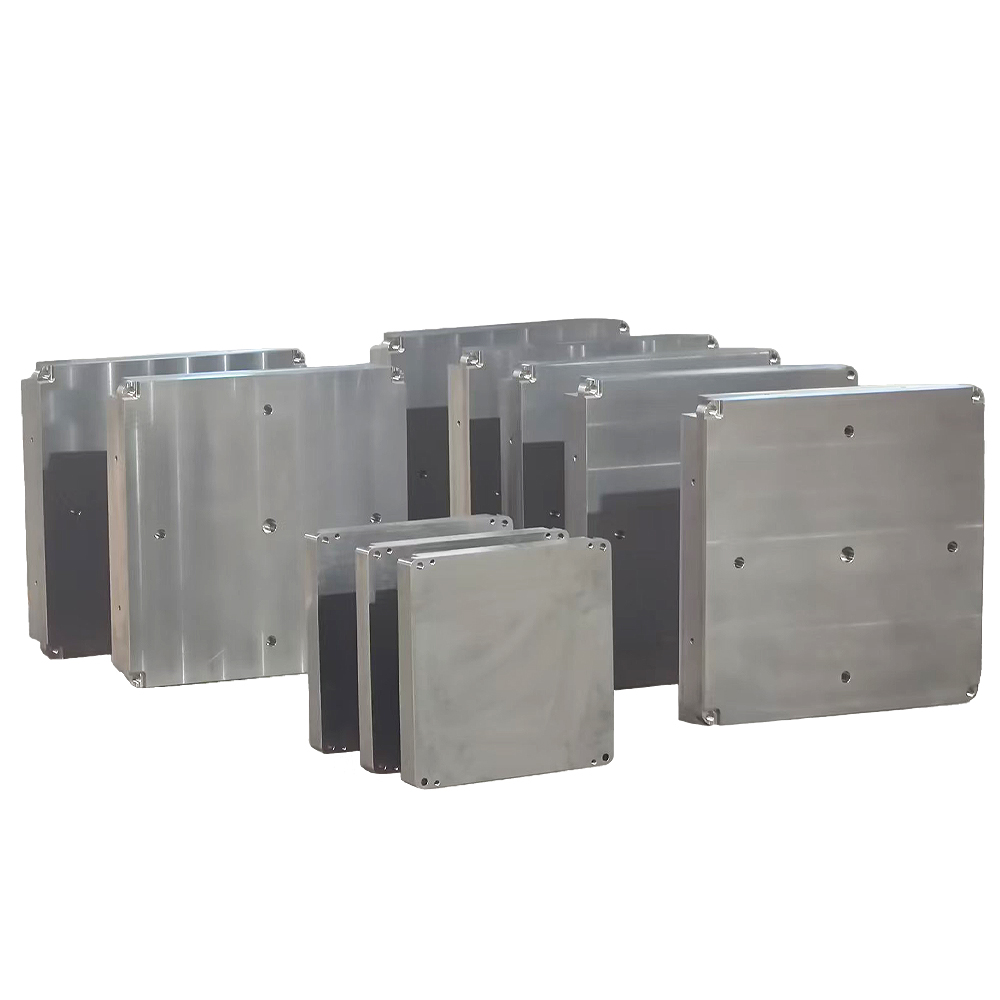

The result is a substrate that delivers excellent dimensional stability, superior adhesion to the powder bed, and reliable release after printing. Whether you are producing jet engine brackets or orthopedic implants, DLX substrates maintain accuracy and surface integrity over hundreds of builds.

Applications Across Key Industries

Aerospace:

Lightweight yet strong, Ti-6Al-4V ELI substrates are used in the production of structural components, turbine housings, and support brackets. Their high temperature resistance and fatigue strength make them essential for printing flight-certified titanium parts.Medical:

In medical 3D printing, purity and biocompatibility are critical. Grade 23 titanium is widely used for manufacturing orthopedic implants, bone scaffolds, and dental prosthetics. DLX’s high-purity substrates ensure clean, contamination-free builds that meet strict regulatory standards.Industrial and Research Applications:

Ti-6Al-4V ELI substrates also support high-end R&D and precision engineering projects, where dimensional accuracy and thermal reliability are priorities.

As additive manufacturing transitions from prototyping to mass production, the demand for premium-grade titanium materials continues to grow. In both aerospace and healthcare, engineers are shifting toward lightweight, high-strength, corrosion-resistant materials that can withstand repetitive laser melting processes without degradation.

The trend toward cleaner alloys like Ti-6Al-4V ELI reflects a broader shift in manufacturing philosophy — prioritizing performance, purity, and recyclability. DLX is at the forefront of this transition, combining material science with advanced fabrication techniques to produce next-generation build substrates.

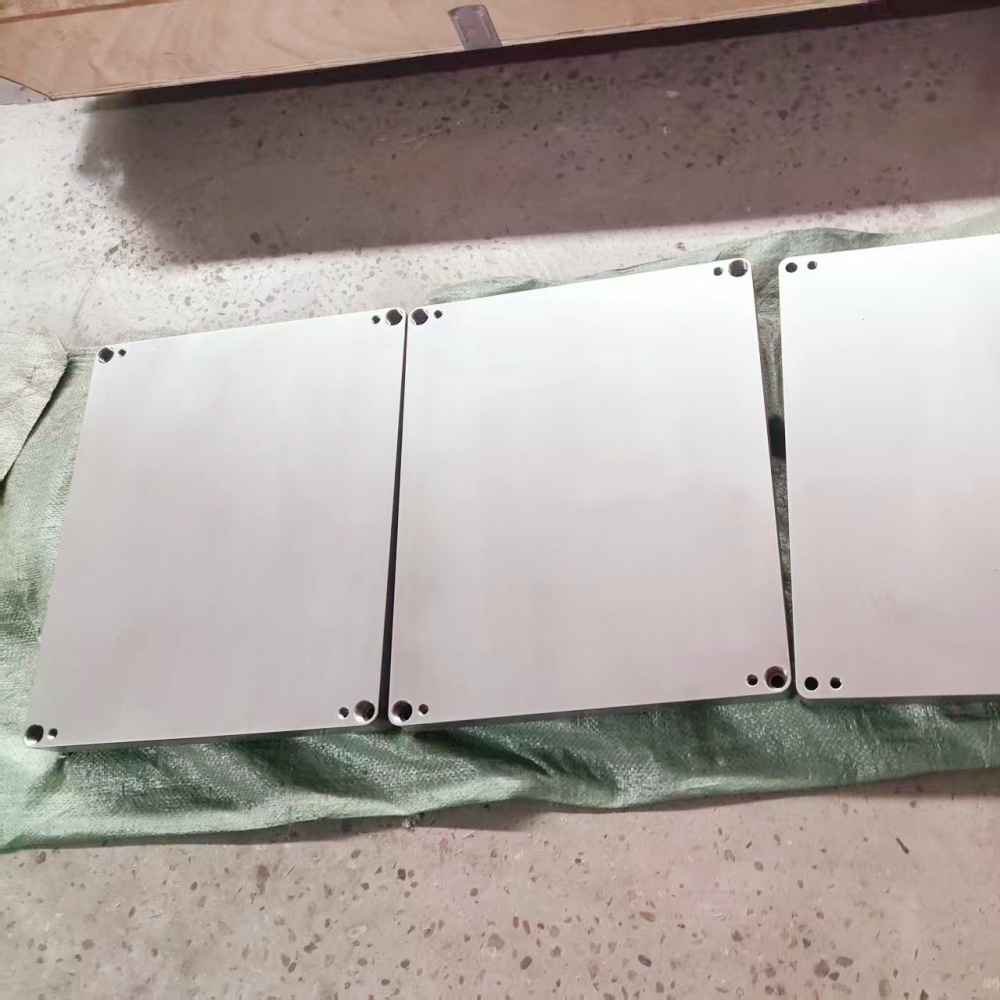

Unlike conventional suppliers, DLX approaches titanium substrate production as a high-precision engineering process. Each plate is meticulously inspected for microstructure consistency, mechanical integrity, and surface precision.

Our manufacturing includes:

Vacuum annealing to reduce residual stress and enhance flatness.

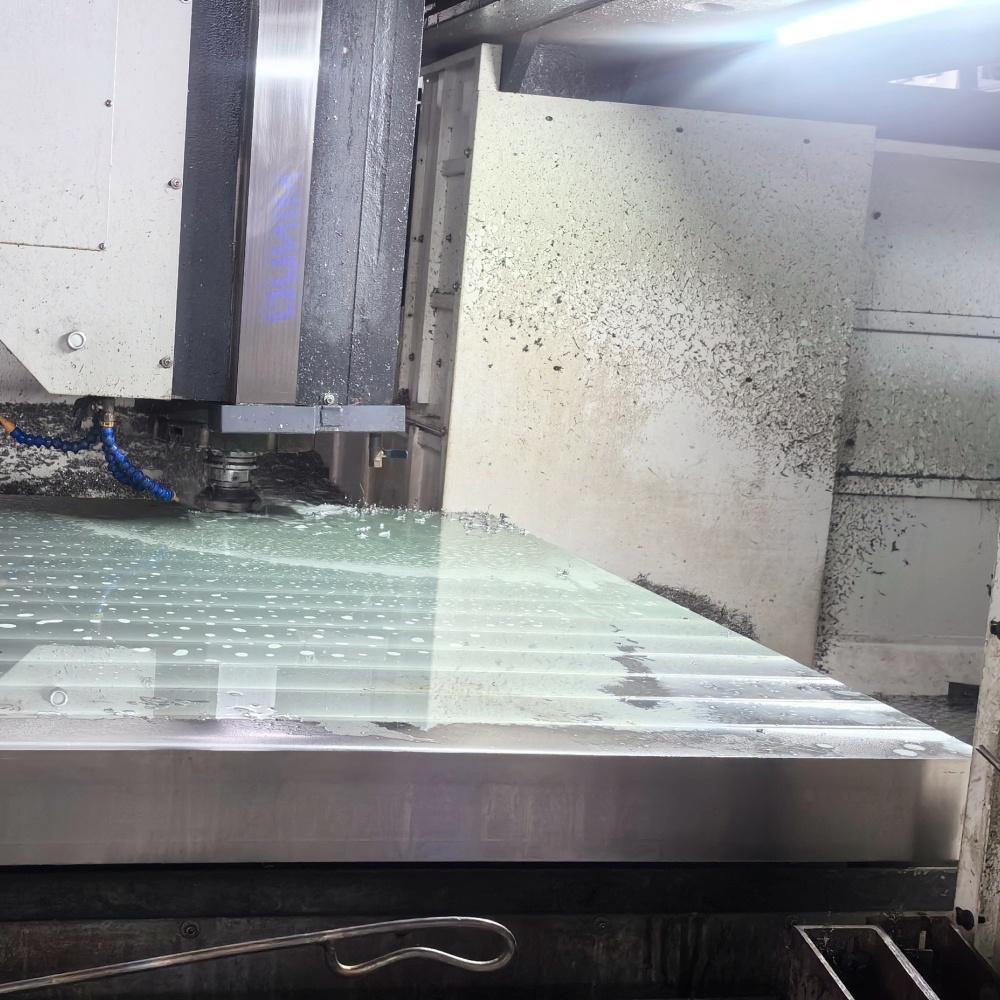

CNC machining for dimensional precision and compatibility with various printer platforms.

Surface passivation to prevent oxidation and improve powder adhesion.

Customized finishes (polished, ground, or etched) based on client needs.

By focusing on quality and repeatability, DLX ensures each substrate not only supports precise builds but also minimizes downtime and maintenance costs.

DLX vs. Traditional Substrate Manufacturers

Many substrate suppliers treat the build plate as a consumable. DLX treats it as a critical component of your printing system. While standard plates may deform or fatigue after dozens of builds, DLX’s Ti-6Al-4V ELI substrates maintain mechanical stability and flatness across hundreds of print cycles.

Our substrates also feature enhanced surface oxidation control, allowing for better adhesion during printing and easier part removal afterward. This dual benefit improves productivity and extends the usable life of the plate — reducing cost per build.

Precision for Medical and Aerospace Applications

DLX’s deep understanding of industry requirements allows us to deliver substrates that meet both aerospace-grade mechanical specifications and medical-grade purity standards. Every substrate is certified and traceable, complete with mechanical test data and flatness inspection reports.

This commitment to traceability and quality control helps customers maintain compliance with international standards while ensuring the reliability of their printed parts.

Titanium is inherently recyclable, and DLX’s refurbishment program further reduces waste. We offer surface reconditioning services that restore used plates to like-new condition, significantly extending their lifecycle and minimizing environmental impact.

The Ti-6Al-4V ELI (Grade 23) Titanium Substrate represents the pinnacle of performance in metal 3D printing. Combining strength, purity, and biocompatibility, it provides the perfect foundation for producing mission-critical aerospace parts and medical implants.

DLX’s expertise in precision machining, vacuum processing, and custom finishing ensures every substrate exceeds industry expectations. With unmatched flatness, longevity, and purity, DLX continues to lead the titanium substrate market — supporting the innovation that defines the future of additive manufacturing.

About Us:

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications.

For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

FAQs:

1. What is Ti-6Al-4V ELI (Grade 23)?

Ti-6Al-4V ELI (Extra Low Interstitial) is a refined version of Grade 5 titanium alloy. It contains lower oxygen and iron content, which improves ductility, toughness, and biocompatibility — making it ideal for aerospace and medical 3D printing applications.

2. How does Grade 23 differ from Grade 5 titanium?

While both alloys share similar strength and corrosion resistance, Grade 23 is purer and less brittle. Its lower interstitial elements enhance fracture toughness, making it safer and more reliable for load-bearing implants and high-stress aerospace components.

3. Why is Ti-6Al-4V ELI preferred for 3D printing substrates?

It offers excellent weldability, dimensional stability, and consistent heat resistance. These properties ensure that during additive manufacturing, the build platform maintains structural integrity and supports high-precision parts.

4. What benefits do DLX titanium substrates provide?

DLX uses vacuum-melted Ti-6Al-4V ELI alloy with strict grain control and stress-relieving treatment. Our substrates deliver ultra-flat surfaces, uniform microstructure, and extended build life, ensuring consistent quality across print cycles.

5. What 3D printing methods are compatible with DLX Grade 23 substrates?

They are compatible with SLM (Selective Laser Melting), DMLS (Direct Metal Laser Sintering), and EBM (Electron Beam Melting) systems, supporting a variety of titanium powder materials.

6. Which industries use Ti-6Al-4V ELI substrates?

Common industries include aerospace, medical devices, defense, and advanced engineering, where lightweight, biocompatible, and high-strength materials are required.

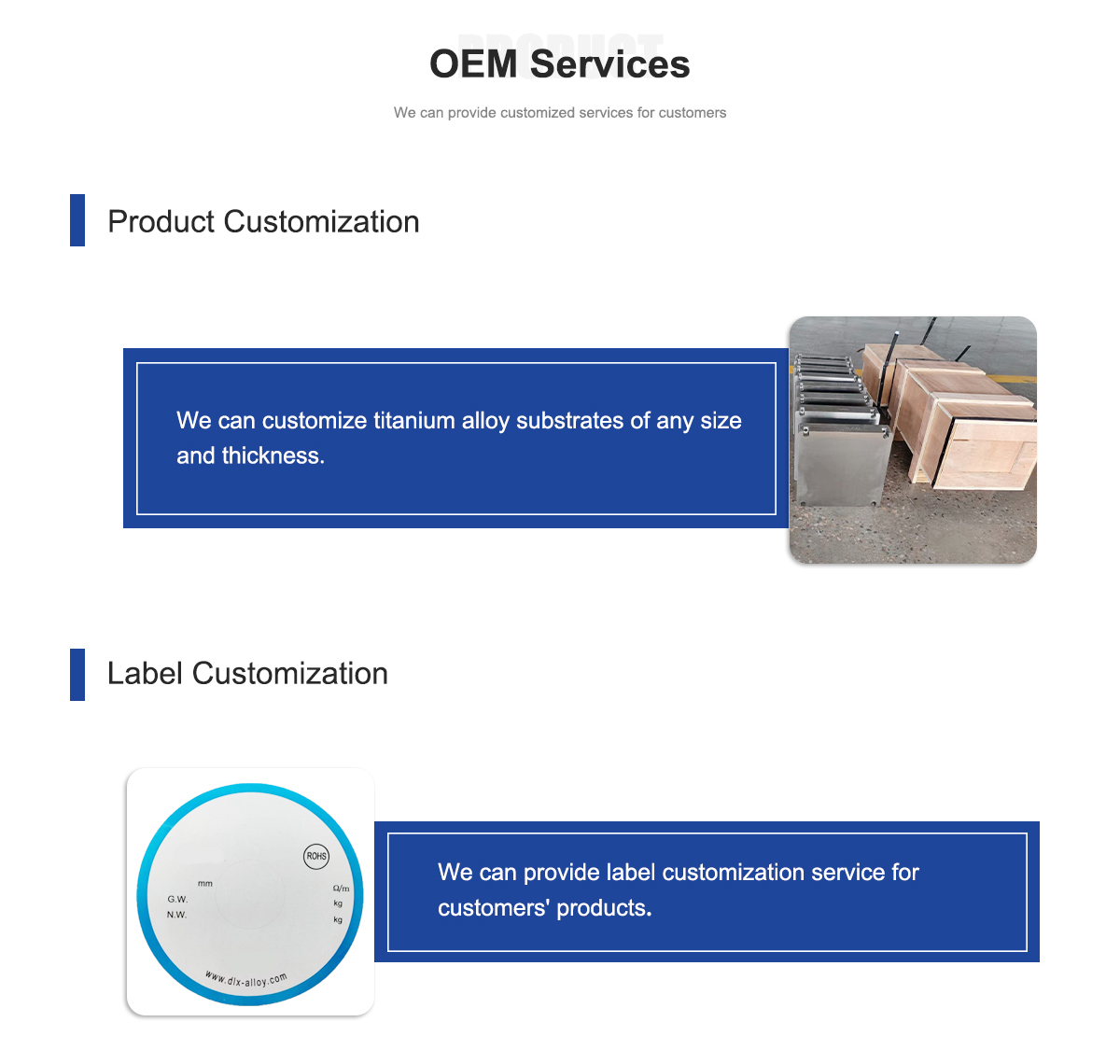

7. Can DLX customize the substrate’s size and surface finish?

Yes. DLX offers custom machining, thickness options, mounting configurations, and surface treatments to fit all major printer platforms and specific user requirements.

8. How long does a DLX Ti-6Al-4V ELI substrate last?

Thanks to advanced heat treatment and stress management, DLX substrates can endure hundreds of build cycles without warping or microcracking, providing exceptional value and durability.