In the world of metal additive manufacturing, precision begins with the surface beneath the print. The build plate — or base plate — plays a vital role in determining how a 3D printed part adheres, forms, and maintains dimensional accuracy. At DLX, we specialize in manufacturing Titanium Alloy build plates designed specifically for SLM (Selective Laser Melting) and DMLS (Direct Metal Laser Sintering) systems, ensuring stability and consistency through every print cycle.

For more details, pls directly contact us.

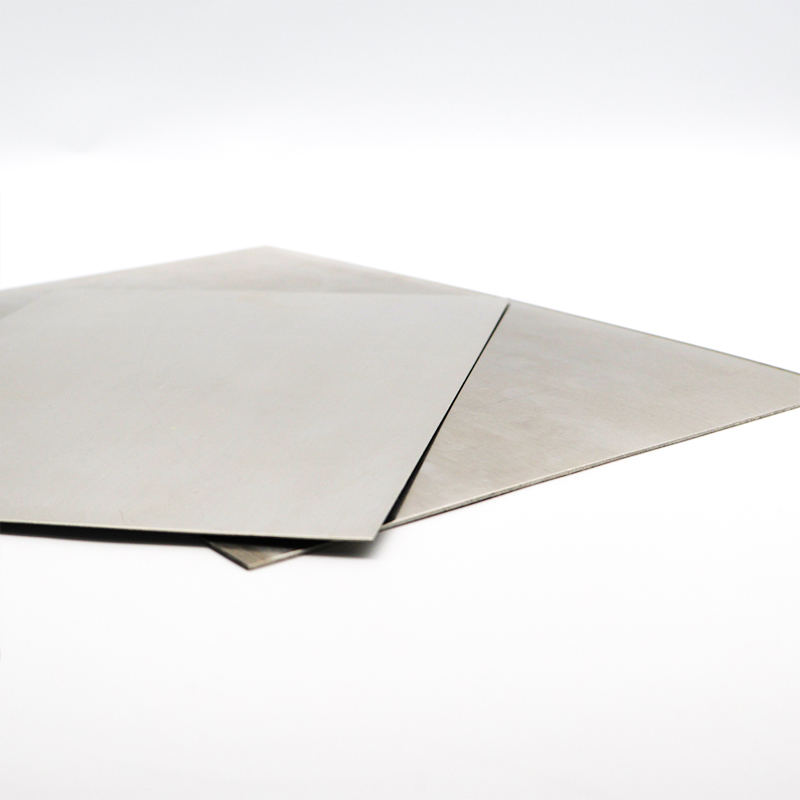

Titanium alloys like Ti6Al4V offer an unmatched combination of high strength, low density, and thermal stability. During the SLM or DMLS process, the build plate endures extreme laser heat and rapid cooling, cycle after cycle. Unlike steel or aluminum, titanium maintains its structure and flatness without distortion. Its low thermal expansion prevents warping, ensuring every layer of powder is deposited on a perfectly stable base.

This reliability makes titanium the material of choice for high-value applications where even microscopic inaccuracies can lead to print failure — such as aerospace components, surgical implants, and precision industrial tools.

Comparison Table

| Property / Feature | Standard Titanium Plate | DLX Titanium Alloy Build Plate | DLX Advantage |

|---|---|---|---|

| Material Grade | Ti6Al4V (Grade 5) | Ti6Al4V (Enhanced) | Optimized grain structure for durability |

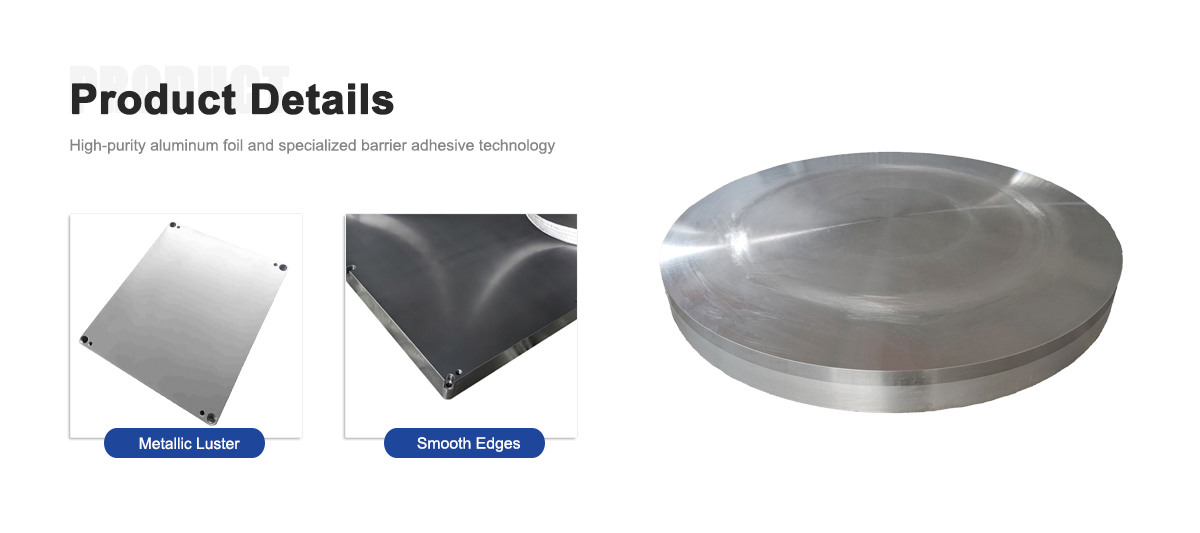

| Flatness Tolerance (mm/m²) | ≤0.1 | ≤0.05 | Ultra-flat CNC precision machining |

| Residual Stress | Moderate | Very Low | Vacuum annealing process |

| Corrosion Resistance | Excellent | Excellent+ | Controlled oxidation surface |

| Thermal Expansion Coefficient | 8.6 µm/m·K | 8.6 µm/m·K | Stable at high temperatures |

| Maximum Operating Temperature (°C) | 600 | 650 | Extended high-temp capability |

| Build Cycle Life | 200–300 | 400–500+ | Longer service life |

| Surface Finish Options | Standard polish | Polished, ground, or treated | Customizable for machine compatibility |

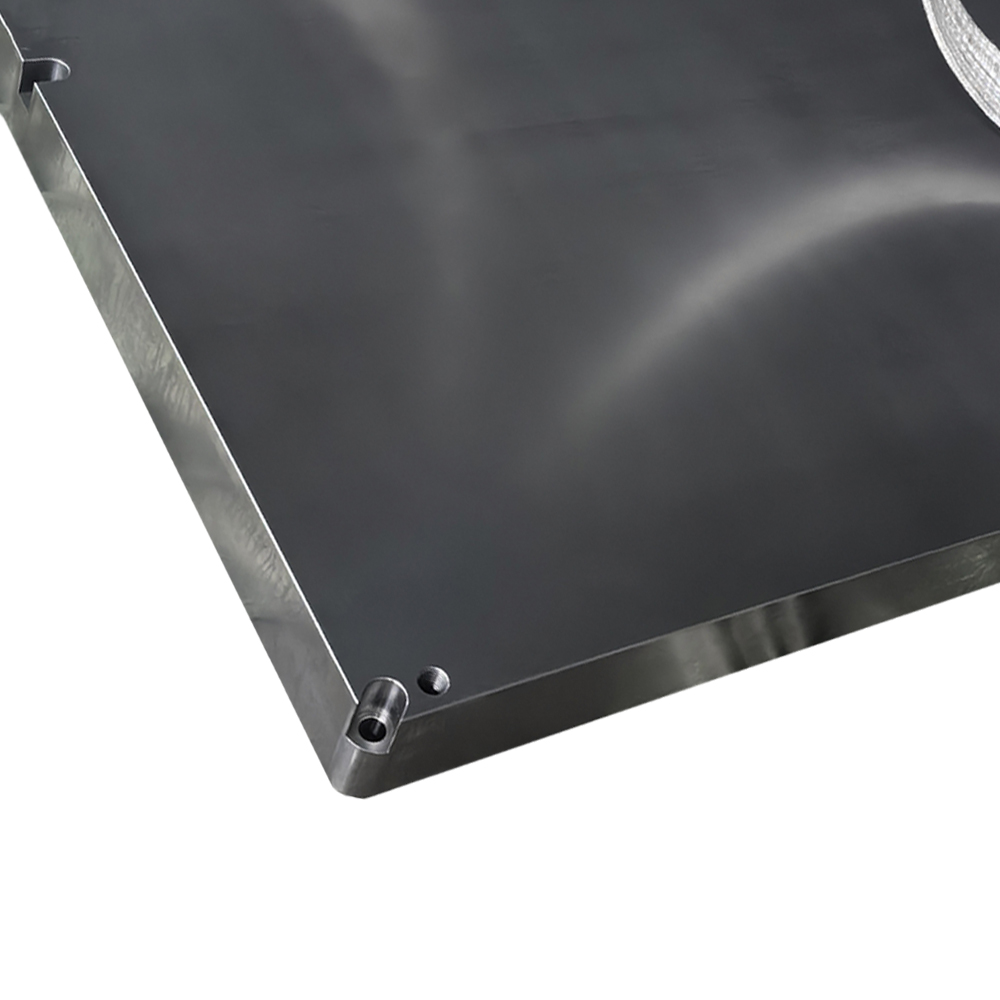

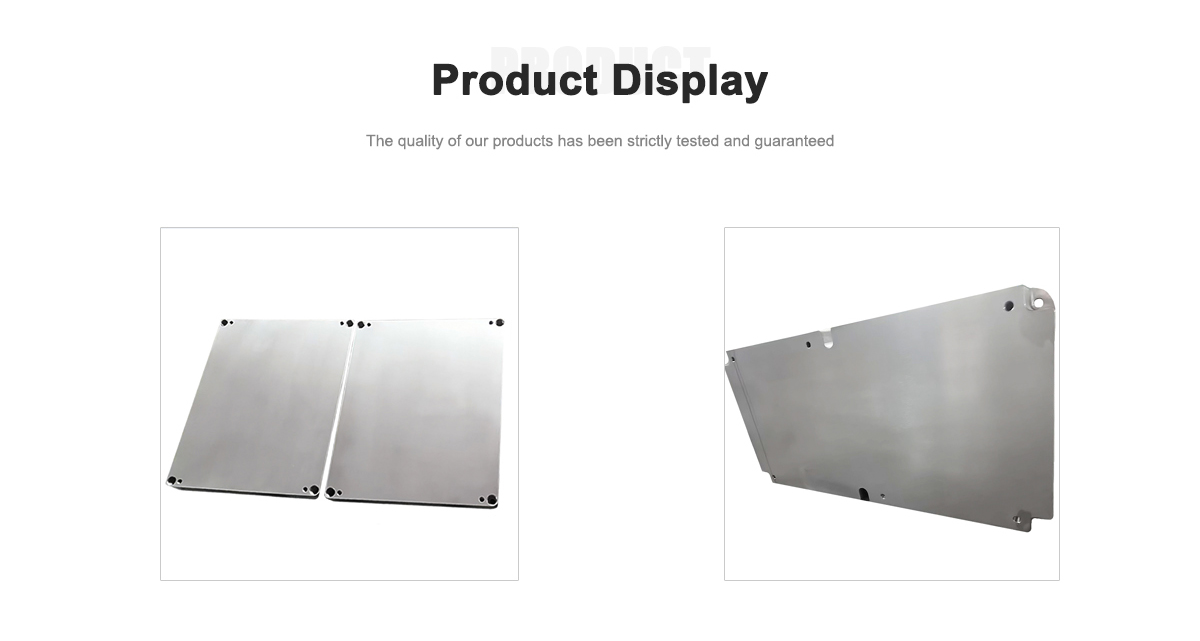

DLX titanium alloy build plates go beyond basic specifications. Our manufacturing process starts with premium titanium billets that undergo double vacuum melting to eliminate inclusions and impurities. The plates are then machined to exact tolerances and heat-treated under controlled conditions to relieve internal stresses.

The result? A substrate that remains flat and dimensionally stable, even after hundreds of print cycles. Our proprietary surface finishing ensures ideal roughness for optimal powder adhesion while still allowing smooth part removal post-printing. Each plate is quality-tested for hardness, flatness, and structural uniformity before shipping.

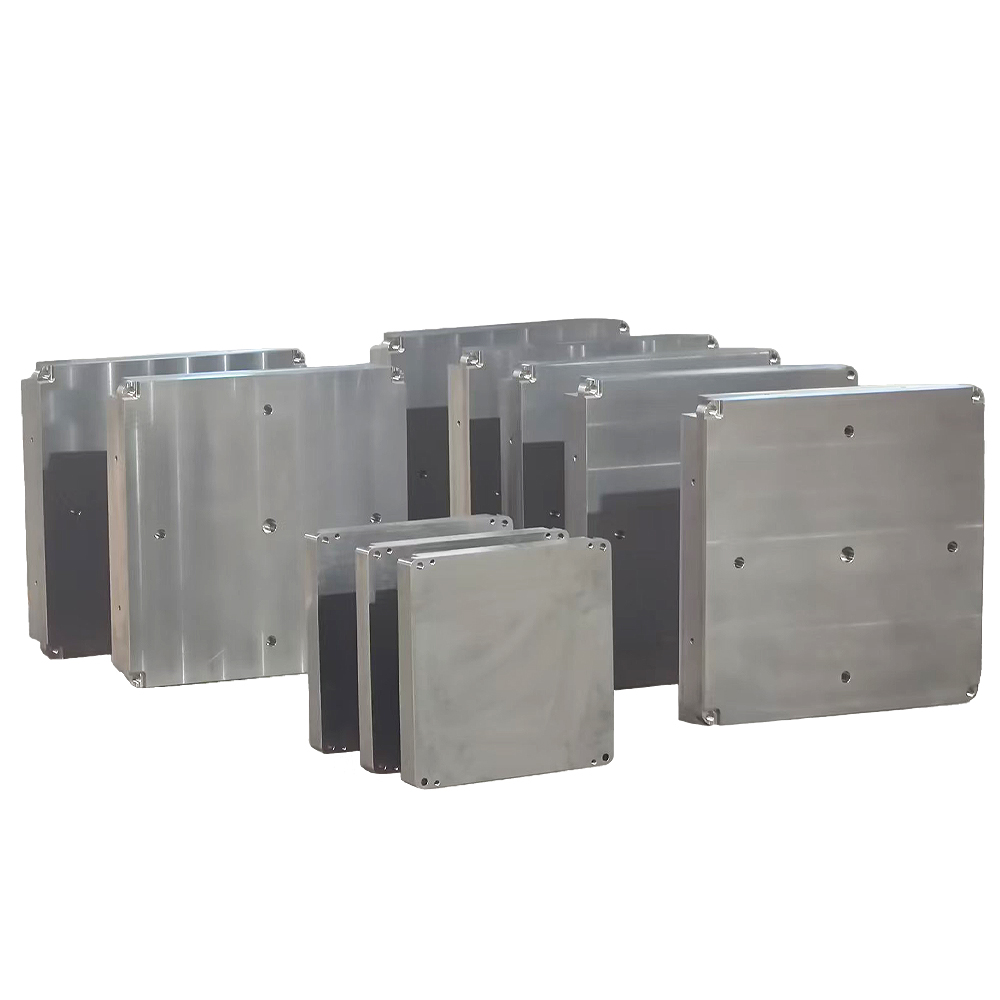

Compatibility and Customization

DLX understands that additive manufacturing systems differ in build sizes, mounting styles, and laser configurations. That’s why we offer fully customizable titanium build plates. Whether your system is large-format or compact, we tailor the dimensions, edge features, and surface treatments to your specific machine requirements.

Our engineers also provide consultation support to help you select the right plate thickness and finish based on your laser type, build chamber conditions, and printing materials. This ensures seamless integration and improved printing performance.

Applications Across Key Industries

Titanium alloy build plates are becoming the backbone of advanced manufacturing sectors:

Aerospace: Used for printing lightweight turbine blades, brackets, and structural components requiring high fatigue resistance.

Medical: Essential for orthopedic implants, dental frameworks, and surgical tools, where biocompatibility and precision are critical.

Automotive: Enables the production of performance parts such as exhaust systems and engine housings with reduced weight and high durability.

Energy and Industrial: Supports 3D printing of components exposed to extreme heat and corrosion, such as heat exchangers or pump housings.

In each application, DLX titanium plates maintain consistent performance, ensuring every layer builds exactly as designed.

Industry Trends and Future Growth

As 3D printing continues to move from prototyping to full-scale industrial production, the demand for robust and repeatable substrates is growing rapidly. Titanium’s ability to maintain stability under laser-based processes makes it an ideal solution for next-generation additive manufacturing systems.

DLX is at the forefront of this shift. By combining precision machining with material science expertise, we’re delivering titanium build plates that help companies scale their production while maintaining accuracy and quality.

Many manufacturers rely on stainless steel or aluminum plates for cost efficiency. However, these materials suffer from thermal deformation and shorter lifespans under repeated use. DLX titanium alloy build plates, on the other hand, provide superior flatness retention, corrosion resistance, and reusability — significantly reducing long-term operating costs.

Furthermore, while some build plates lose their structural integrity after dozens of cycles, DLX titanium substrates continue performing consistently beyond 400–500 builds. The combination of vacuum annealing and CNC precision ensures minimal residual stress, enhancing both surface stability and powder adhesion reliability.

Sustainability and Longevity

DLX titanium build plates are designed with sustainability in mind. By offering refurbishment and resurfacing services, we extend the lifecycle of each plate, reducing material waste. Clients can restore their build plates to near-original condition without the need for complete replacement — a cost-effective and eco-friendly approach.

The Titanium Alloy Build Plate for SLM and DMLS 3D Printers represents more than just a piece of hardware — it’s the foundation of precision additive manufacturing. DLX’s commitment to quality, customization, and durability ensures that every print starts with confidence.

Our titanium plates are engineered to perform in the toughest industrial environments, combining mechanical integrity with exceptional longevity. Whether you’re producing aerospace components or medical-grade implants, DLX build plates deliver the consistency and performance that define world-class 3D printing.

About Us:

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications.

For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

FAQs:

1. What is a titanium alloy build plate?

A titanium alloy build plate is the foundation surface used in metal 3D printing systems such as SLM (Selective Laser Melting) and DMLS (Direct Metal Laser Sintering). It provides excellent thermal stability, corrosion resistance, and strength to support precise, high-quality builds.

2. Why is titanium alloy ideal for 3D printing platforms?

Titanium alloys have a high strength-to-weight ratio, low thermal expansion, and outstanding resistance to warping. These features ensure dimensional accuracy and repeatability during high-temperature laser printing processes.

3. What grades of titanium are typically used for build plates?

Common grades include Ti6Al4V (Grade 5) and Ti-6Al-4V ELI (Grade 23). DLX primarily uses Ti6Al4V for its exceptional strength and long service life under repeated thermal cycling.

4. What makes DLX titanium build plates stand out?

DLX uses precision CNC machining, vacuum annealing, and surface optimization to achieve ultra-flat surfaces with minimal residual stress. This ensures reliable adhesion and easier part removal after printing.

5. Are DLX build plates compatible with most SLM and DMLS machines?

Yes. DLX build plates can be customized to fit popular printer models, including various dimensions, mounting hole configurations, and surface finishes, ensuring seamless compatibility with your printing system.

6. How long does a titanium build plate last?

DLX titanium build plates are designed for extended use, often lasting hundreds of build cycles. Proper maintenance, including regular cleaning and calibration, can further increase their lifespan.

7. In which industries are titanium alloy build plates commonly used?

They are widely used in aerospace, medical, and industrial manufacturing, where precision, durability, and material purity are critical to achieving consistent results.

8. Can the surface be refurbished after repeated printing?

Yes. DLX provides surface regrinding and reconditioning services, restoring the flatness and surface integrity of build plates after extended use, maximizing cost efficiency.