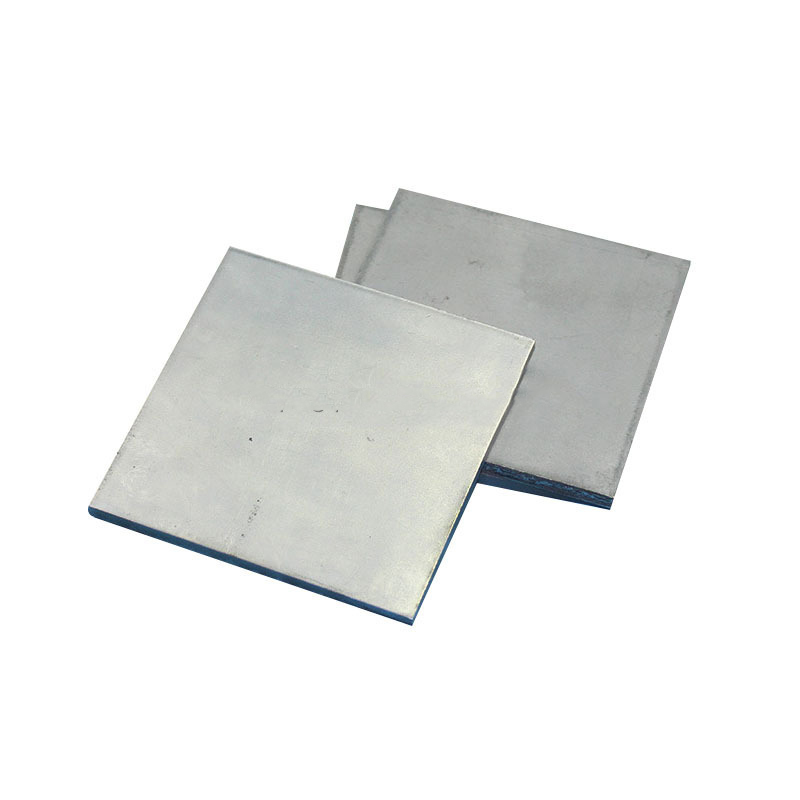

Our Grade 2 Titanium Plate s are engineered to thrive in harsh marine environments, where corrosion resistance is non-negotiable. Made from commercially pure titanium (CP Ti), these plates offer an unbeatable combination of strength, low weight, and exceptional resistance to seawater, salt spray, and other corrosive elements. With a density of just 4.5 g/cm³—nearly half that of steel—our plates deliver durability without adding unnecessary bulk, making them ideal for marine applications like shipbuilding, offshore platforms, and desalination systems.

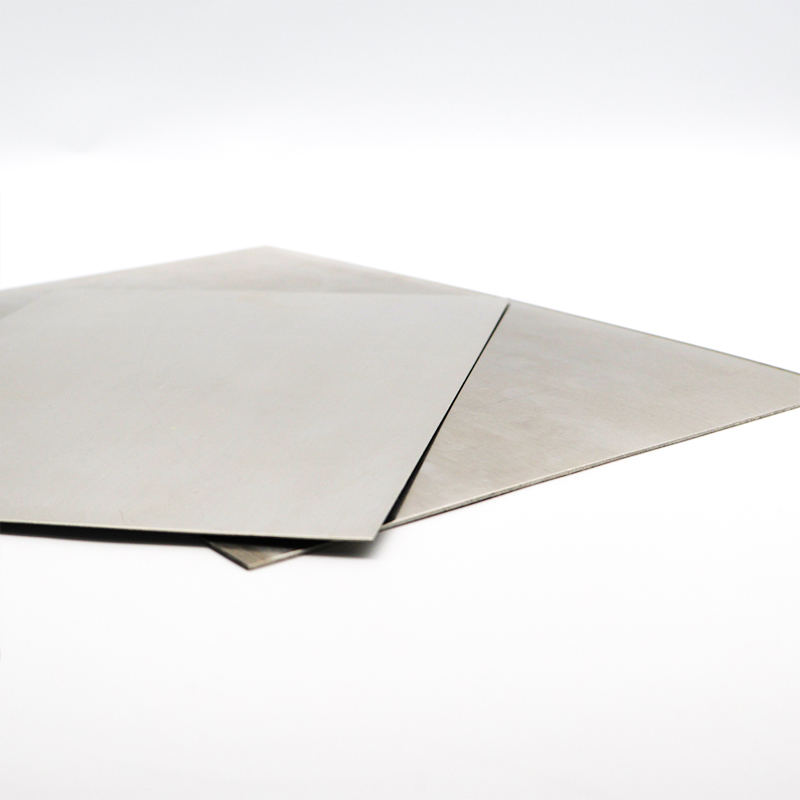

Conforming to ASTM B265 standards, our Grade 2 titanium plates provide excellent ductility and formability, allowing for easy fabrication into complex shapes. Available in thicknesses from 0.5 mm to 100 mm and customizable sizes, they suit a range of marine projects, from hull components to heat exchanger plates. Our advanced manufacturing, including vacuum arc melting and precision rolling, ensures defect-free plates with consistent mechanical properties. These plates resist pitting, crevice corrosion, and galvanic corrosion, even in warm, chloride-rich waters, ensuring long-term performance in the toughest conditions.

We prioritize sustainability, using recyclable titanium and eco-friendly production methods. Our plates are lightweight, reducing fuel consumption in marine vessels, and their longevity minimizes maintenance costs. For marine engineers seeking reliable, high-performance materials, our Grade 2 titanium plates are a top choice.

For more details, pls directly contact us.

The marine industry is navigating a wave of growth, driven by global trade, offshore energy exploration, and sustainable technologies. The marine titanium market is projected to grow at a CAGR of 4.5% through 2030, fueled by demand for corrosion-resistant materials in shipbuilding, offshore oil and gas, and desalination. Titanium’s ability to withstand seawater’s corrosive effects makes it a standout choice, particularly for applications where steel or aluminum falter. Grade 2 titanium, with its balance of strength, formability, and corrosion resistance, is a staple in marine engineering.

Key trends include the rise of green shipping, with stricter regulations pushing for fuel-efficient, low-emission vessels. Titanium’s lightweight properties help reduce fuel consumption, aligning with these goals. The offshore wind and renewable energy sectors are also driving demand, as titanium plates are used in turbine foundations and subsea equipment exposed to harsh marine conditions. Additionally, desalination plants are expanding to meet global water needs, with titanium’s resistance to chloride-induced corrosion making it essential for heat exchangers and piping.

Challenges like high raw material costs and titanium’s complex machining persist, but its long-term cost savings—through reduced maintenance and extended equipment life—offset these hurdles. Supply chain stability is critical, as titanium is considered a strategic resource in some regions. Our company mitigates this with a robust global supply chain and innovative manufacturing, ensuring consistent availability. The push for digitalization, with IoT-enabled monitoring in marine systems, also opens new opportunities for titanium’s use in smart, durable components.

| Titanium (Ti) | Aluminum (Al) | Vanadium (V) | Tin (Sn) | |

| Ti-6Al-4V | Rest | 5.5%-6.8% | 3.5%-4.5% | |

| Ti-5Al-2.5Sn | Rest | 4.5%-5.5% | 2.0%-3.0% |

Physical Properties

| Density | 4.4-4.5g/cm³ |

| Melting Point | 1660°C |

| Coefficient of Thermal Expansion | 8-10×10⁻⁶/K (20°C-500°C) |

| Thermal Conductivity | 6-22 W/(m·K) (depending on alloy grade) |

| Electrical Resistivity | 0.14-0.17 μΩ·m |

| Tensile Strength | 600-1200 MPa (depending on alloy grade) |

| Yield Strength | 480-1100 MPa |

| Elongation at Break | 10%-25% |

| Hardness | 200-400 HB |

For more details, pls directly contact us.

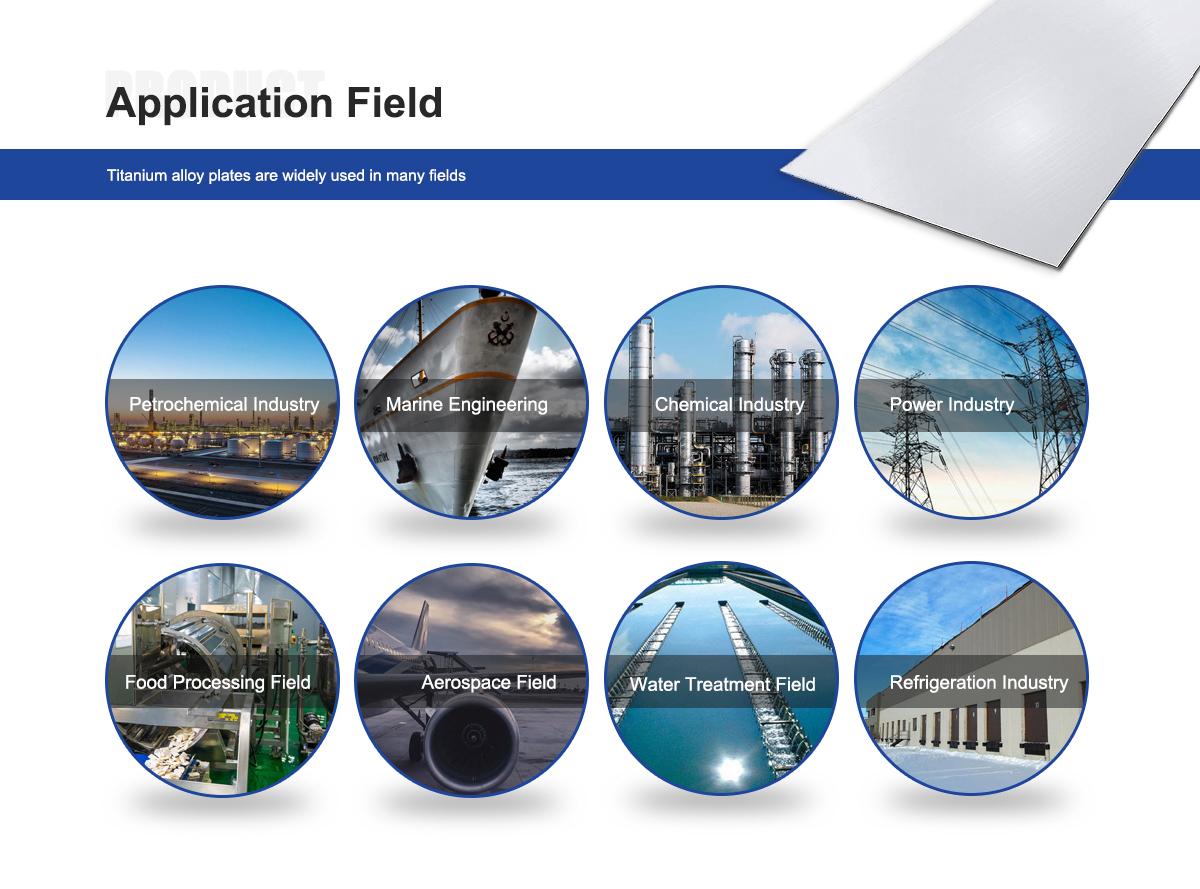

Our Grade 2 titanium plates are versatile, serving critical roles in marine environments and beyond:

-

Shipbuilding: Used in hulls, superstructures, and propeller shafts, our plates resist seawater corrosion, reducing maintenance and extending vessel life.

-

Offshore Platforms: Ideal for risers, pipelines, and structural components in oil and gas platforms, where they withstand harsh saltwater and weather conditions.

-

Desalination Plants: Our plates are used in heat exchangers and evaporators, resisting corrosion from high-salinity water and aggressive cleaning agents.

-

Marine Heat Exchangers: Their high thermal conductivity and corrosion resistance make them perfect for plate-and-frame or shell-and-tube heat exchangers in marine systems.

-

Subsea Equipment: From underwater cables to ROV components, our plates ensure durability in deep-sea environments with high pressure and corrosive conditions.

-

Marine Renewable Energy: Used in tidal and offshore wind turbine structures, our plates provide long-term reliability in corrosive marine settings.

-

Yacht and Leisure Craft: Lightweight and corrosion-resistant, our plates enhance fuel efficiency and aesthetics in high-end marine vessels.

-

Naval Applications: Our plates are used in military vessels and submarines, offering strength and corrosion resistance for critical structural components

Comparison Parameters Table

|

Parameter |

Our Titanium Plates |

Competitor A |

Competitor B |

|---|---|---|---|

|

Material |

CP Titanium (Grade 2) |

CP Titanium (Grade 2) |

Stainless Steel (316L) |

|

Corrosion Resistance |

Excellent (seawater, chlorides) |

Good |

Moderate (prone to pitting) |

|

Tensile Strength |

550 MPa |

500 MPa |

580 MPa |

|

Density |

4.5 g/cm³ |

4.5 g/cm³ |

8.0 g/cm³ |

|

Thermal Conductivity |

16 W/m·K |

15 W/m·K |

16 W/m·K |

|

Formability |

Excellent (high ductility) |

Good |

Moderate |

|

Customization Options |

High (sizes, thicknesses, finishes) |

Moderate |

Limited |

|

Standards Compliance |

ASTM B265 |

ASTM B265 |

ASTM A240 |

Company Advantages

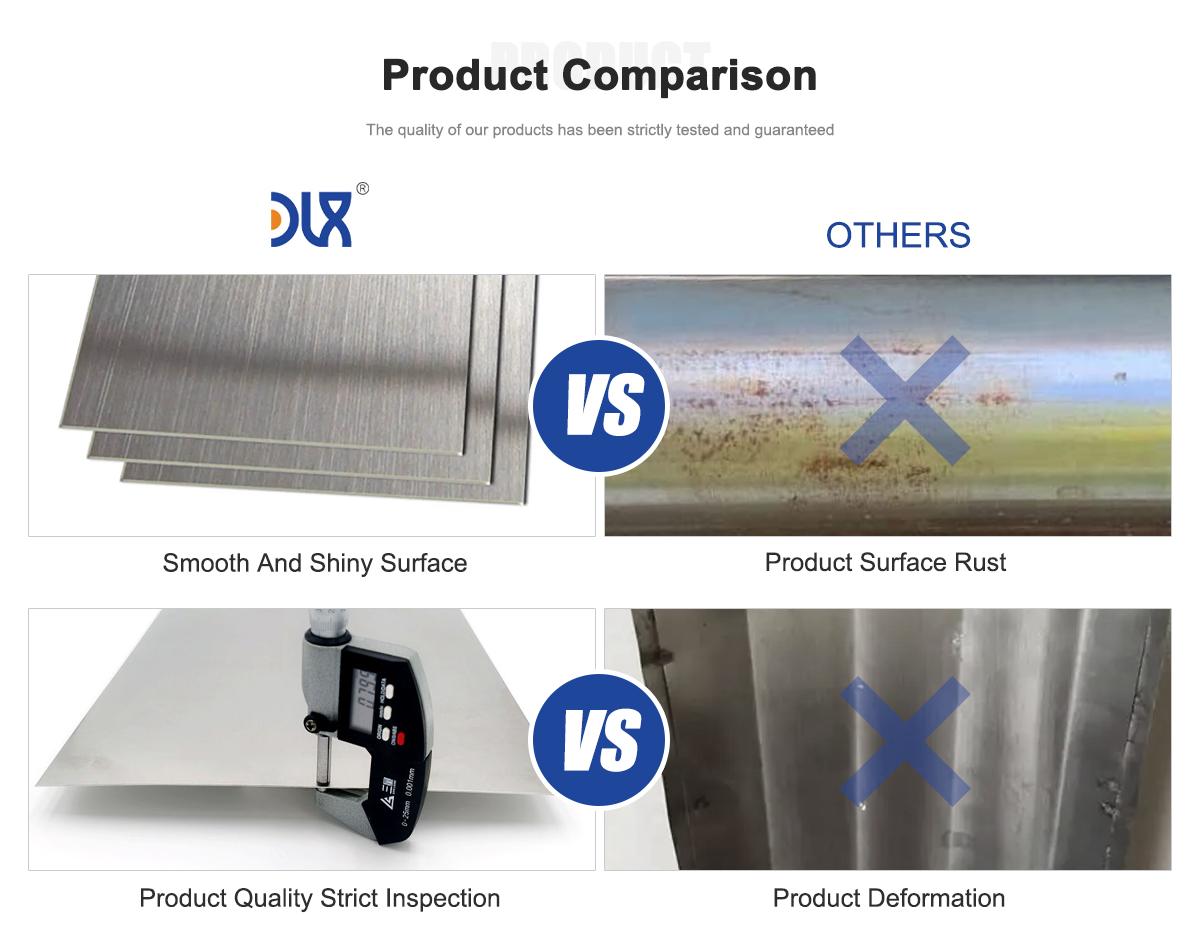

Our Grade 2 titanium plates are a cut above, designed specifically for marine environments. We use state-of-the-art vacuum arc melting and precision rolling to produce plates with flawless grain structures, ensuring top-notch corrosion resistance and mechanical performance. Unlike others, we offer extensive customization, from tailored sizes to specialized surface treatments, so you get exactly what your project demands.

Our supply chain is rock-solid, securing high-quality titanium even in volatile markets, so you’re never left waiting. We’re also pushing the envelope with additive manufacturing, creating complex plate designs that optimize performance and reduce waste. Sustainability is at our core—our plates are fully recyclable, and our production minimizes environmental impact, aligning with the marine industry’s green goals.

With decades of experience, we’ve mastered the art of delivering cost-effective, high-performance titanium plates. Our R&D team is constantly innovating, developing alloys and processes to meet the evolving needs of marine engineering, from deep-sea exploration to renewable energy. Our global network of service centers ensures fast delivery, and our plates’ durability translates to lower maintenance costs, saving you money over the long haul. We’re the reliable partner marine industries trust for quality and performance.

Why Choose Our Titanium Plates?

Our Grade 2 titanium plates are built to conquer the harshest marine environments, offering unmatched corrosion resistance, lightweight strength, and long-term reliability. Whether you’re constructing ships, offshore platforms, or desalination systems, our plates deliver the performance you need to keep operations running smoothly. With cutting-edge manufacturing, a commitment to sustainability, and a focus on customer needs, we’re here to power your marine projects with top-quality titanium solutions.

For more details, pls directly contact us.

About Us:

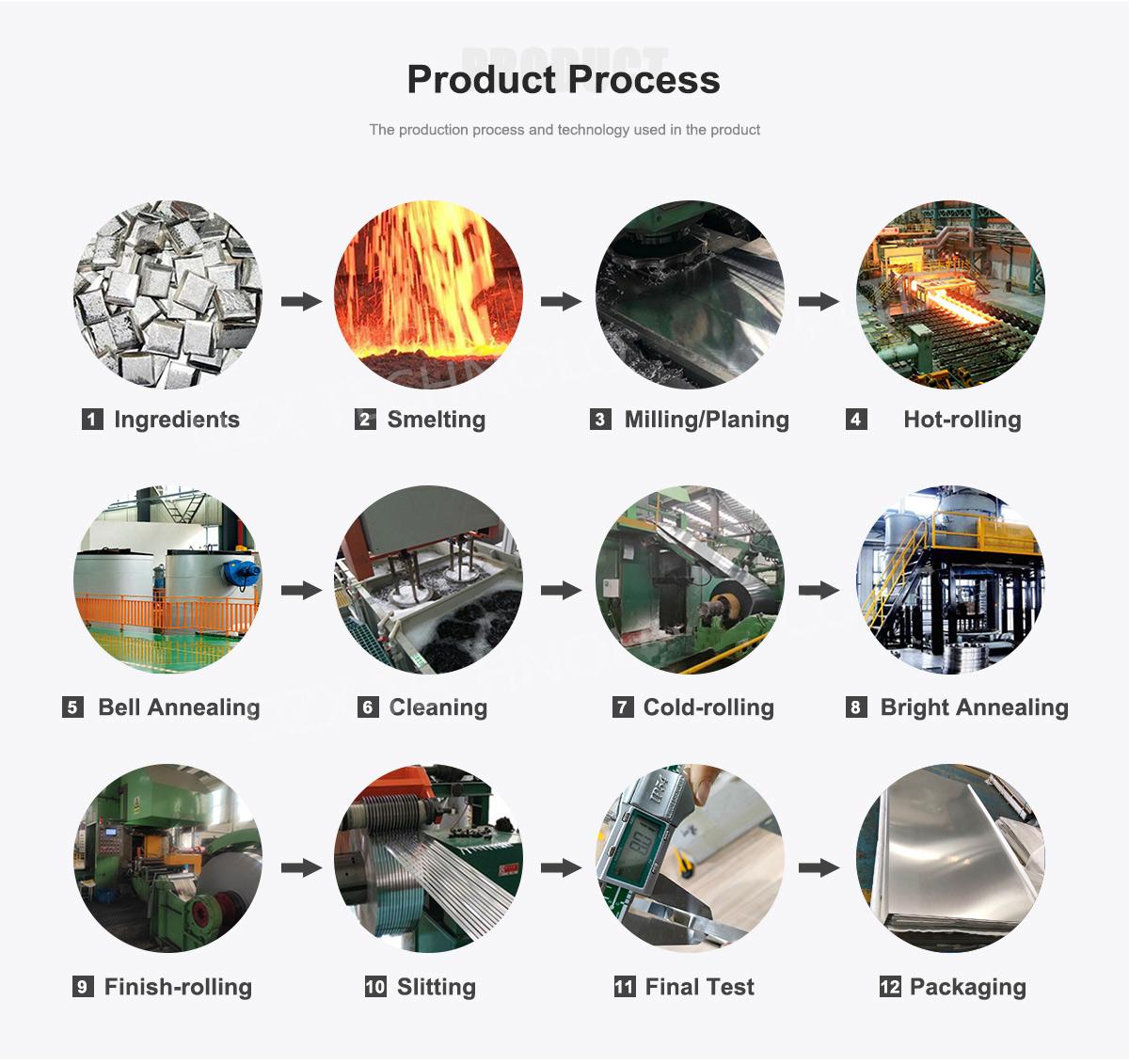

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications.

For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

FAQs:

-

Why is Grade 2 titanium ideal for marine environments?

It offers excellent corrosion resistance to seawater, salt spray, and chlorides, plus high strength and low weight. -

What standards do your titanium plates meet?

Our plates comply with ASTM B265, ensuring quality and reliability for marine applications. -

Can your plates be customized?

Yes, we offer custom sizes, thicknesses, and finishes to fit specific marine project needs. -

How do your plates perform in corrosive environments?

They resist pitting, crevice, and galvanic corrosion, even in warm, chloride-rich seawater. -

Are your titanium plates recyclable?

Absolutely, titanium is fully recyclable, supporting eco-friendly marine engineering. -

What marine applications use your plates?

Shipbuilding, offshore platforms, desalination, heat exchangers, subsea equipment, and renewable energy systems. -

How do you ensure plate quality?

We use vacuum arc melting, precision rolling, and rigorous testing to deliver defect-free plates. -

Do your plates reduce maintenance costs?

Yes, their corrosion resistance and durability minimize maintenance and extend equipment life.