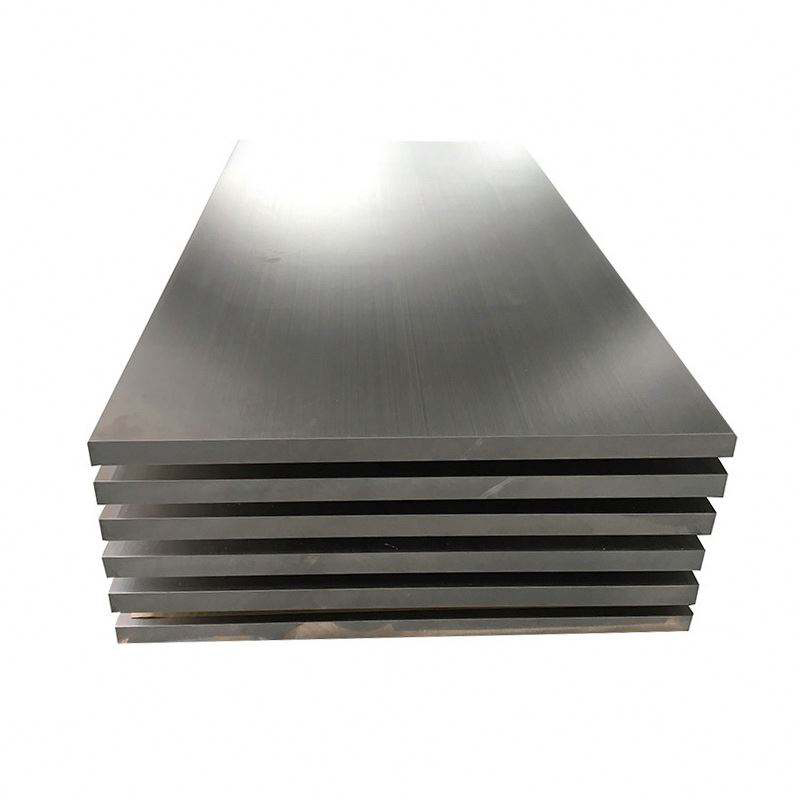

Our Grade 5 Titanium Plate s, made from the powerhouse Ti-6Al-4V alloy, are built for the high-stakes world of aerospace. Known for their killer strength-to-weight ratio, these plates deliver a tensile strength of up to 1000 MPa while keeping things light at a density of 4.42 g/cm³—nearly half that of steel. They’re corrosion-resistant, handle extreme temperatures up to 600°C, and shrug off fatigue, making them perfect for aircraft components that need to perform under pressure.

Certified to ASTM B265 and AMS 4911 standards, our plates come in thicknesses from 0.5 mm to 100 mm and can be customized to fit precise aerospace designs, from wing spars to engine parts. We use cutting-edge manufacturing like vacuum arc melting, precision forging, and CNC machining to churn out defect-free plates with top-notch mechanical properties. These plates resist corrosion from jet fuel, moisture, and high-altitude conditions, ensuring long-term reliability.

We keep sustainability in mind, using recyclable titanium and efficient production to cut waste. Their durability means less maintenance and longer component life, saving costs in the long run. For aerospace engineers chasing performance and reliability, our Grade 5 titanium plates are the ultimate choice.

For more details, pls directly contact us.

The aerospace industry is flying high, driven by demand for fuel-efficient aircraft, military advancements, and space exploration. The global titanium market, valued at USD 20.4 billion in 2024, is set to grow at a CAGR of 5.4% through 2032, with Grade 5 titanium leading the charge in aerospace due to its strength and lightweight properties. Aircraft like the Boeing 787 and F-35 rely heavily on titanium, with some using up to 15–39% by weight for critical components.

Trends like sustainable aviation are pushing for lighter materials to cut fuel use and emissions—global air traffic has tripled since 1990, and efficiency is key. Additive manufacturing is a game-changer, allowing complex titanium parts with less waste, aligning with green goals. The rise of space tourism and unmanned aerial vehicles is also spiking demand for high-strength materials like our plates. Meanwhile, Industry 4.0 brings smart manufacturing, with IoT and predictive maintenance optimizing production.

Challenges include titanium’s higher cost and machining complexity compared to aluminum or composites. But its durability and performance in extreme conditions make it worth it. Supply chain hiccups, especially for titanium sponge, can be a pain, but our robust sourcing keeps us steady. The push for hypersonic flight and deep-space missions is opening new doors for titanium in cutting-edge aerospace projects.

| Titanium (Ti) | Aluminum (Al) | Vanadium (V) | Tin (Sn) | |

| Ti-6Al-4V | Rest | 5.5%-6.8% | 3.5%-4.5% | |

| Ti-5Al-2.5Sn | Rest | 4.5%-5.5% | 2.0%-3.0% |

Physical Properties

| Density | 4.4-4.5g/cm³ |

| Melting Point | 1660°C |

| Coefficient of Thermal Expansion | 8-10×10⁻⁶/K (20°C-500°C) |

| Thermal Conductivity | 6-22 W/(m·K) (depending on alloy grade) |

| Electrical Resistivity | 0.14-0.17 μΩ·m |

| Tensile Strength | 600-1200 MPa (depending on alloy grade) |

| Yield Strength | 480-1100 MPa |

| Elongation at Break | 10%-25% |

| Hardness | 200-400 HB |

For more details, pls directly contact us.

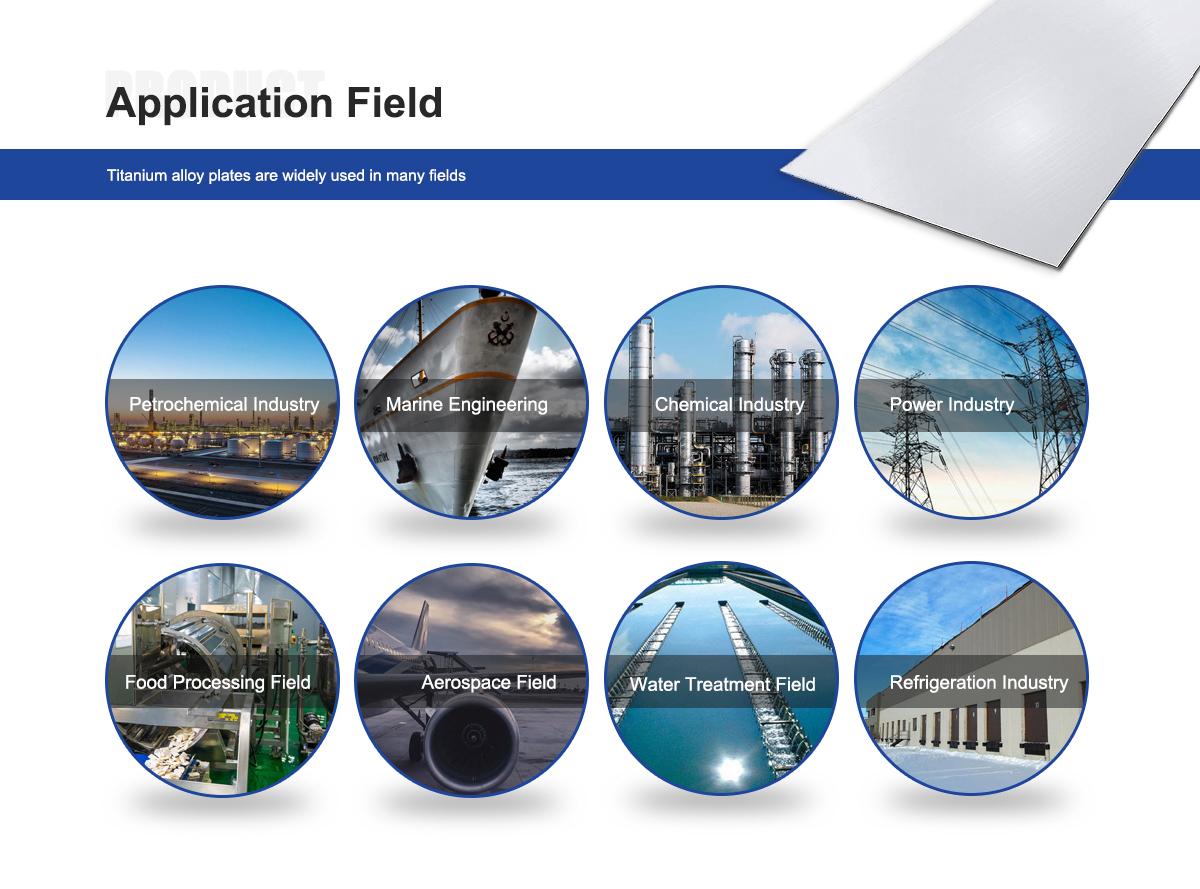

Our Grade 5 titanium plates are workhorses in aerospace and beyond:

-

Airframes: Used in fuselage panels, wing spars, and bulkheads, our plates provide strength and light weight for structural integrity.

-

Jet Engines: They handle extreme heat in compressor blades, turbine discs, and casings, ensuring reliable performance.

-

Landing Gear: With high fatigue strength, our plates are perfect for landing gear components enduring cyclic loads.

-

Spacecraft: Used in fuel tanks, structural supports, and heat shields, they withstand radiation and thermal stress in space.

-

Fasteners: Our plates are machined into lightweight, corrosion-resistant bolts and screws for critical assemblies.

-

Hydraulic Systems: They’re used in tubing and fittings, resisting corrosion and pressure in aircraft hydraulics.

-

Military Aircraft: Our plates support high-stress components in fighters and drones, delivering durability under combat conditions.

-

Commercial Aircraft: Used in passenger jets, they improve fuel efficiency and reduce maintenance costs.

Comparison Parameters Table

|

Parameter |

Our Titanium Plates |

Competitor A |

Competitor B |

|---|---|---|---|

|

Material |

Grade 5 (Ti-6Al-4V) |

Grade 2 Titanium |

Aluminum (7075) |

|

Tensile Strength |

1000 MPa |

550 MPa |

570 MPa |

|

Corrosion Resistance |

Excellent (jet fuel, moisture, high altitude) |

Excellent |

Moderate (prone to corrosion) |

|

Density |

4.42 g/cm³ |

4.5 g/cm³ |

2.81 g/cm³ |

|

Temperature Resistance |

Up to 600°C |

Up to 400°C |

Up to 120°C |

|

Fatigue Strength |

450–515 MPa |

300–350 MPa |

160–200 MPa |

|

Customization Options |

Extensive (sizes, thicknesses, finishes) |

Limited |

Moderate |

|

Standards Compliance |

ASTM B265, AMS 4911 |

ASTM B265 |

ASTM B209 |

Company Advantages

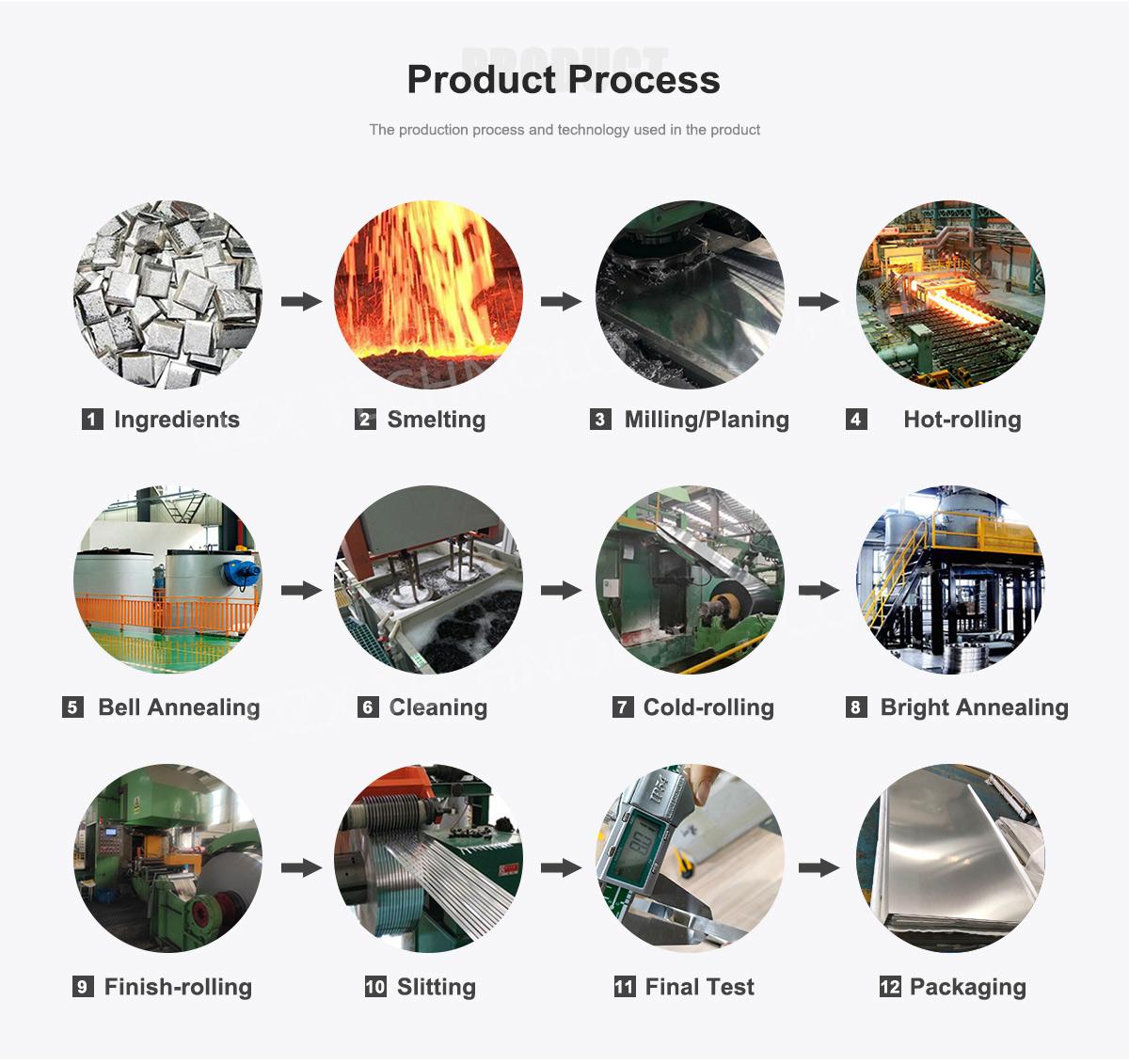

Our Grade 5 titanium plates are a cut above for aerospace applications. We use state-of-the-art vacuum arc melting, precision forging, and CNC machining to produce plates with unbeatable strength and consistency. Unlike others, we offer full customization, tailoring sizes, thicknesses, and finishes to meet your exact specs, whether for airframes or engine components. This ensures seamless integration and top performance in your projects.

Our supply chain is rock-solid, securing premium titanium even in volatile markets, so you never face delays. We’re also pushing boundaries with additive manufacturing, crafting complex parts with minimal waste, which keeps costs down and aligns with sustainability goals. Our plates are fully recyclable, and our production minimizes environmental impact, supporting green aerospace initiatives.

With decades of expertise, we deliver plates that meet the strictest aerospace standards. Our R&D team is always innovating, developing alloys and processes for next-gen applications like hypersonic flight and space exploration. Our global network ensures fast inventory access, and our plates’ durability means less maintenance and longer component life, saving you money. We’re the trusted partner for aerospace manufacturers who demand strength, precision, and reliability.

Why Choose Our Titanium Plates?

Our Grade 5 titanium plates are built to power aerospace applications, delivering high strength, corrosion resistance, and lightweight performance for critical components. From jet engines to spacecraft, they keep your projects soaring with minimal downtime. With cutting-edge manufacturing, a focus on sustainability, and a commitment to your success, we’re here to make your aerospace dreams a reality.

For more details, pls directly contact us.

About Us:

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications.

For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

FAQs:

-

Why use Grade 5 titanium for aerospace?

It offers high strength, light weight, and corrosion resistance, perfect for demanding aircraft components. -

What standards do your plates meet?

They comply with ASTM B265 and AMS 4911 for aerospace-grade quality. -

Can your plates be customized?

Yes, we tailor sizes, thicknesses, and finishes to fit specific aerospace designs. -

How do your plates handle extreme temperatures?

They perform reliably up to 600°C, ideal for jet engines and high-stress parts. -

Are your titanium plates recyclable?

Absolutely, titanium is fully recyclable, supporting sustainable aerospace manufacturing. -

What aerospace applications use your plates?

Airframes, jet engines, landing gear, spacecraft, fasteners, hydraulic systems, and military aircraft. -

How do you ensure plate quality?

We use vacuum arc melting, precision forging, CNC machining, and rigorous testing for defect-free plates. -

Do your plates reduce maintenance costs?

Yes, their durability and corrosion resistance minimize downtime and repairs.