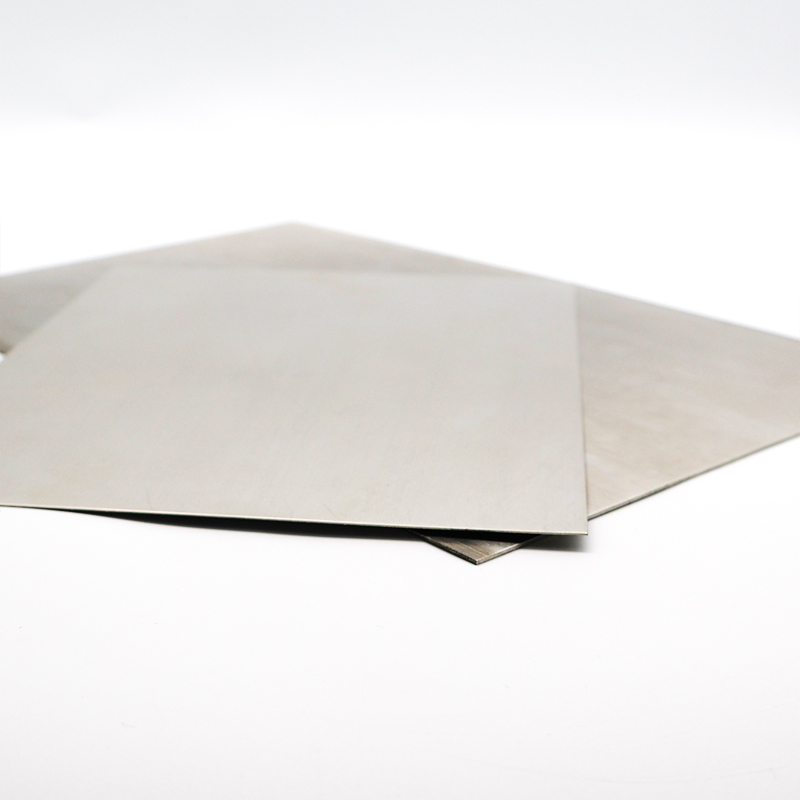

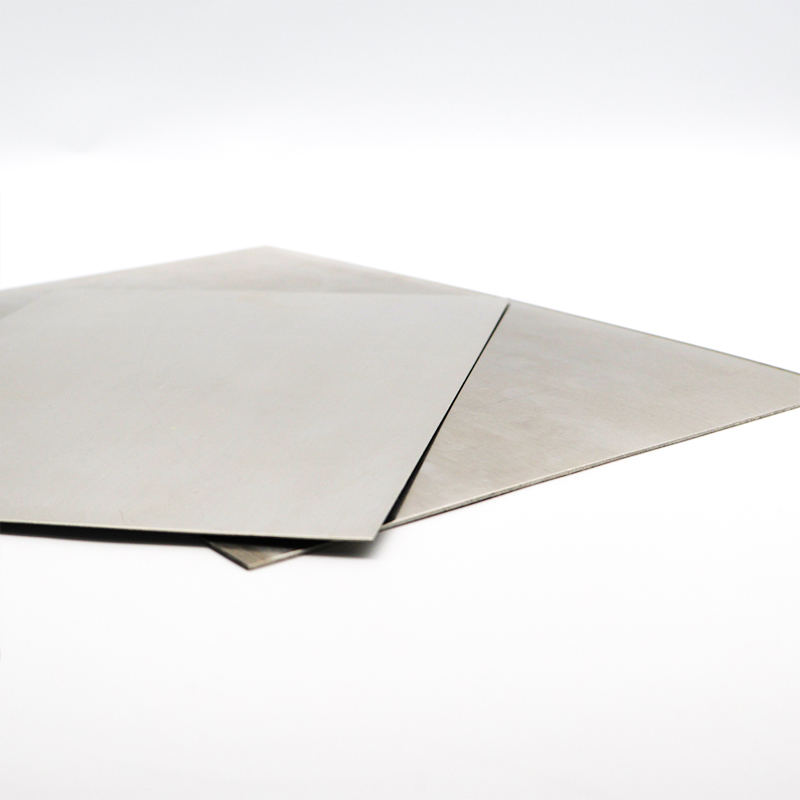

Our medical-grade Titanium Plate s are crafted to meet the exacting demands of orthopedic implants, offering a perfect blend of strength, biocompatibility, and corrosion resistance. Made primarily from Grade 2 (commercially pure) titanium and Grade 5 (Ti-6Al-4V) alloy, these plates provide exceptional durability with a density of 4.5 g/cm³—about half that of steel—making them lightweight yet robust for applications like bone fixation and joint replacements. Their biocompatibility ensures they integrate seamlessly with the human body, minimizing rejection risks.

Certified to ASTM F67 (Grade 2) and ASTM F136 (Grade 5) standards for medical use, our plates are available in thicknesses from 0.5 mm to 50 mm and can be customized to precise specifications using advanced CNC machining and laser cutting. We employ vacuum arc melting and stringent quality controls to produce defect-free plates with ultra-low impurities, ensuring safety and reliability in surgical applications. These plates resist corrosion from bodily fluids and sterilization processes, making them ideal for long-term implants.

We prioritize sustainability with recyclable titanium and efficient production to reduce waste. Their durability means fewer revisions or replacements, improving patient outcomes and reducing costs. For orthopedic surgeons and implant manufacturers, our titanium plates are a trusted, high-performance solution.

For more details, pls directly contact us.

The orthopedic implant market is booming, driven by an aging population, rising joint replacement surgeries, and advances in medical technology. Valued at USD 47.1 billion in 2024, the global orthopedic market is projected to grow at a CAGR of 5.7% through 2032, with titanium leading as a preferred material due to its biocompatibility and strength. Grade 2 and Grade 5 titanium are staples in implants like plates, screws, and joint components, thanks to their ability to integrate with bone and resist corrosion.

Key trends include the rise of minimally invasive surgeries, which demand precision-engineered implants, and personalized medicine, with custom implants tailored to patient anatomy. Additive manufacturing is transforming the industry, enabling complex, patient-specific titanium designs with less waste, aligning with sustainability goals. The adoption of robotics and 3D imaging in orthopedic surgeries is also increasing, requiring materials like titanium that offer reliability and precision. Regulatory standards, like those from the FDA and ISO 13485, are tightening, emphasizing the need for high-purity, traceable materials.

Challenges include titanium’s higher cost compared to stainless steel and the complexity of machining precise implant shapes. However, its superior biocompatibility and longevity outweigh these hurdles, reducing revision surgeries. Supply chain stability for medical-grade titanium is critical, and our robust sourcing ensures consistent quality. The growing demand for orthopedic solutions in emerging markets, coupled with advancements in osseointegration, is driving titanium’s role in next-gen implants.

| Titanium (Ti) | Aluminum (Al) | Vanadium (V) | Tin (Sn) | |

| Ti-6Al-4V | Rest | 5.5%-6.8% | 3.5%-4.5% | |

| Ti-5Al-2.5Sn | Rest | 4.5%-5.5% | 2.0%-3.0% |

Physical Properties

| Density | 4.4-4.5g/cm³ |

| Melting Point | 1660°C |

| Coefficient of Thermal Expansion | 8-10×10⁻⁶/K (20°C-500°C) |

| Thermal Conductivity | 6-22 W/(m·K) (depending on alloy grade) |

| Electrical Resistivity | 0.14-0.17 μΩ·m |

| Tensile Strength | 600-1200 MPa (depending on alloy grade) |

| Yield Strength | 480-1100 MPa |

| Elongation at Break | 10%-25% |

| Hardness | 200-400 HB |

For more details, pls directly contact us.

Our medical-grade titanium plates are versatile, serving critical roles in orthopedic implants and related fields:

-

Bone Fixation Plates: Used in fracture repair for bones like the femur, tibia, and clavicle, our plates provide strength and stability during healing.

-

Joint Replacements: Crafted into components for hip, knee, and shoulder implants, they ensure durability and biocompatibility.

-

Spinal Implants: Our plates are used in spinal fusion devices, offering strength and corrosion resistance for long-term support.

-

Craniofacial Reconstruction: They’re ideal for skull plates and facial implants, integrating seamlessly with bone tissue.

-

Dental Implants: Our plates support dental frameworks, resisting corrosion from saliva and oral environments.

-

Surgical Instruments: Machined into lightweight, durable tools, they withstand repeated sterilization without degrading.

-

Trauma Devices: Used in external fixators and intramedullary nails, our plates provide robust support for severe injuries.

-

Orthopedic Prosthetics: They’re crafted into structural components for prosthetic limbs, balancing strength and light weight.

Comparison Parameters Table

|

Parameter |

Our Titanium Plates |

Competitor A |

Competitor B |

|---|---|---|---|

|

Material |

Grade 2, Grade 5 (Ti-6Al-4V) |

Grade 2 Titanium |

Stainless Steel (316L) |

|

Tensile Strength |

550 MPa (Grade 2), 1000 MPa (Grade 5) |

550 MPa |

580 MPa |

|

Biocompatibility |

Excellent (no rejection risk) |

Excellent |

Good (higher rejection risk) |

|

Density |

4.5 g/cm³ |

4.5 g/cm³ |

8.0 g/cm³ |

|

Corrosion Resistance |

Excellent (bodily fluids, sterilization) |

Excellent |

Moderate (prone to pitting) |

|

Customization Options |

Extensive (sizes, shapes, finishes) |

Limited |

Moderate |

|

Manufacturing Process |

Vacuum arc melting, CNC machining, laser cutting |

Basic machining |

Standard fabrication |

|

Standards Compliance |

ASTM F67, ASTM F136 |

ASTM F67 |

ASTM F138 |

Company Advantages

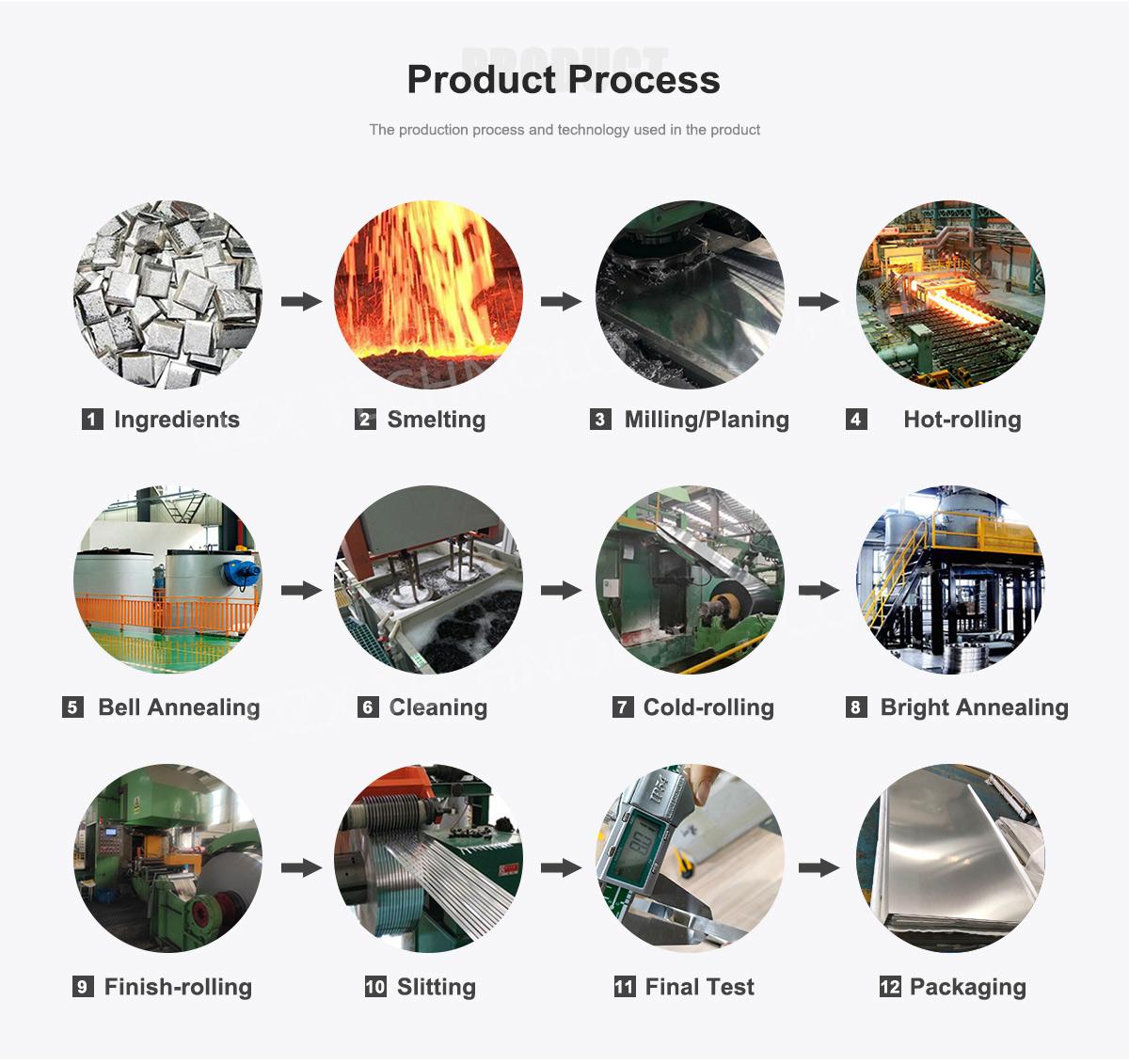

Our medical-grade titanium plates are a cut above for orthopedic implants. We use advanced vacuum arc melting, precision CNC machining, and laser cutting to produce plates with ultra-low impurities and flawless performance. Unlike others, we offer extensive customization, tailoring sizes, shapes, and finishes to match your exact implant designs, ensuring perfect fit and patient safety.

Our supply chain is rock-solid, securing medical-grade titanium even in tight markets, so your production stays on schedule. We’re also pushing the envelope with additive manufacturing, creating complex, patient-specific implants with minimal waste, which keeps costs down and supports sustainability. Our plates are fully recyclable, and our production minimizes environmental impact, aligning with green medical trends.

With decades of expertise, we deliver plates that meet the strictest medical standards. Our R&D team is always innovating, developing processes for next-gen implants, like 3D-printed bone scaffolds and smart prosthetics. Our global network ensures fast inventory access, and our plates’ durability means fewer revision surgeries, improving patient outcomes and saving costs. We’re the trusted partner for orthopedic manufacturers who demand precision, safety, and reliability.

Why Choose Our Titanium Plates?

Our medical-grade titanium plates are built to power orthopedic implants, delivering biocompatibility, strength, and corrosion resistance for life-changing surgeries. From bone fixation to joint replacements, they ensure durability and patient safety with minimal complications. With cutting-edge manufacturing, a focus on sustainability, and a commitment to your success, we’re here to make your orthopedic projects thrive.

For more details, pls directly contact us.

About Us:

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications.

For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

FAQs:

-

Why use titanium plates for orthopedic implants?

They offer biocompatibility, strength, and corrosion resistance, ideal for safe, long-term implants. -

What titanium grades do you use?

Grade 2 for corrosion resistance and Grade 5 for higher strength in load-bearing implants. -

Do your plates meet medical standards?

Yes, they comply with ASTM F67 and ASTM F136 for medical-grade quality. -

Can your plates be customized?

Absolutely, we tailor sizes, thicknesses, and shapes to fit specific implant designs. -

How do your plates perform in the body?

They resist corrosion from bodily fluids and integrate well with bone, minimizing rejection. -

Are your titanium plates recyclable?

Yes, titanium is fully recyclable, supporting sustainable medical manufacturing. -

What applications use your plates?

Bone fixation, joint replacements, spinal implants, craniofacial, dental, surgical tools, trauma devices, and prosthetics. -

How do you ensure plate quality?

We use vacuum arc melting, precision machining, and strict testing to ensure defect-free, high-purity plates.