Our Titanium Plate s for biomedical applications and surgical tools are designed to meet the stringent demands of the medical field, delivering top-notch biocompatibility, strength, and corrosion resistance. Crafted primarily from Grade 2 (commercially pure) titanium and Grade 5 (Ti-6Al-4V) alloy, these plates offer a lightweight profile with a density of 4.5 g/cm³—about half that of steel—making them ideal for implants and precision instruments. Their ability to integrate with human tissue without causing adverse reactions is a game-changer for patient outcomes.

Certified to ASTM F67 (Grade 2) and ASTM F136 (Grade 5) standards for medical use, our plates are available in thicknesses from 0.3 mm to 50 mm and can be tailored to exact specifications using advanced CNC machining and laser cutting. We employ vacuum arc melting and rigorous quality controls to ensure ultra-low impurities, guaranteeing safety for surgical and implant applications. These plates resist corrosion from bodily fluids, saline, and aggressive sterilization processes, ensuring long-term reliability.

We prioritize sustainability with recyclable titanium and efficient production to minimize waste. Their durability reduces the need for replacement surgeries or tool repairs, saving costs and improving patient care. For biomedical engineers and surgical tool manufacturers, our titanium plates are a reliable, high-performance solution.

For more details, pls directly contact us.

The biomedical industry is thriving, fueled by an aging population, advancements in medical technology, and rising demand for minimally invasive procedures. The global medical titanium market, part of the broader USD 20.4 billion titanium market in 2024, is projected to grow at a CAGR of 5.4% through 2032. Titanium’s biocompatibility, corrosion resistance, and strength make it a cornerstone for implants and surgical tools, with Grade 2 and Grade 5 dominating due to their proven safety and performance.

Key trends include the rise of personalized medicine, with patient-specific implants crafted via additive manufacturing, which reduces waste and enhances precision. The adoption of robotics in surgeries is growing, requiring lightweight, durable materials for tools like scalpels and retractors. Sustainability is a major driver—titanium’s recyclability aligns with eco-friendly medical manufacturing goals. Regulatory standards, such as FDA and ISO 13485, are tightening, emphasizing the need for high-purity, traceable materials to ensure patient safety.

Challenges include titanium’s higher cost compared to alternatives like stainless steel and the complexity of machining intricate medical components. However, its longevity and biocompatibility reduce revision surgeries, making it a cost-effective choice over time. Supply chain stability for medical-grade titanium is critical, and our robust sourcing ensures consistent quality. The growth of regenerative medicine and smart implants with embedded sensors is further boosting demand for titanium in cutting-edge biomedical applications.

| Titanium (Ti) | Aluminum (Al) | Vanadium (V) | Tin (Sn) | |

| Ti-6Al-4V | Rest | 5.5%-6.8% | 3.5%-4.5% | |

| Ti-5Al-2.5Sn | Rest | 4.5%-5.5% | 2.0%-3.0% |

Physical Properties

| Density | 4.4-4.5g/cm³ |

| Melting Point | 1660°C |

| Coefficient of Thermal Expansion | 8-10×10⁻⁶/K (20°C-500°C) |

| Thermal Conductivity | 6-22 W/(m·K) (depending on alloy grade) |

| Electrical Resistivity | 0.14-0.17 μΩ·m |

| Tensile Strength | 600-1200 MPa (depending on alloy grade) |

| Yield Strength | 480-1100 MPa |

| Elongation at Break | 10%-25% |

| Hardness | 200-400 HB |

For more details, pls directly contact us.

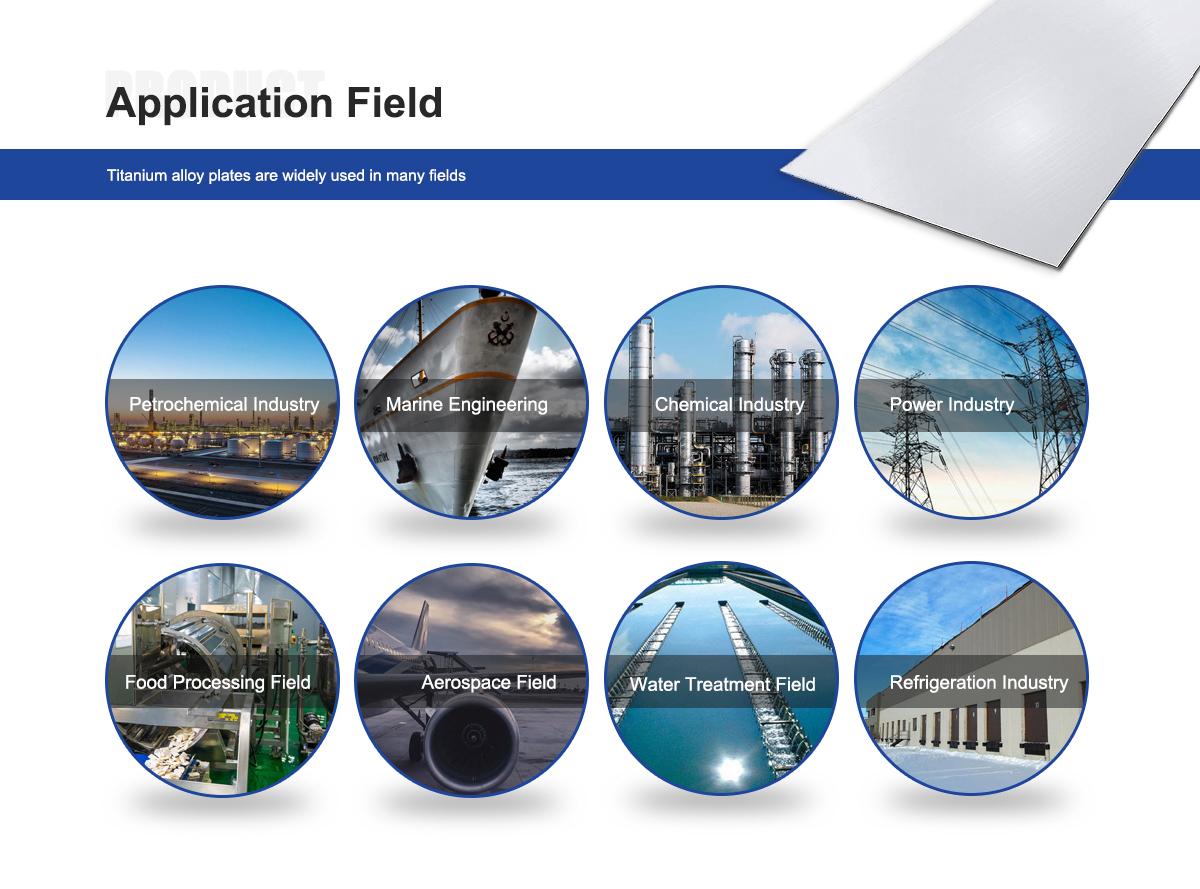

Our titanium plates are versatile, serving critical roles in biomedical applications and surgical tools:

-

Orthopedic Implants: Used in bone plates, screws, and joint replacements, our plates provide strength and biocompatibility for fracture repair and joint reconstruction.

-

Dental Implants: They’re crafted into dental frameworks and abutments, resisting corrosion from saliva and ensuring long-term stability.

-

Spinal Implants: Our plates support spinal fusion devices, offering durability and integration with bone tissue.

-

Craniofacial Reconstruction: Used in skull plates and facial implants, they ensure biocompatibility and structural support.

-

Surgical Instruments: Machined into scalpels, forceps, and retractors, our plates withstand repeated sterilization without degrading.

-

Cardiovascular Devices: They’re used in pacemaker casings and stent frameworks, offering corrosion resistance and lightweight strength.

-

Prosthetic Components: Our plates are crafted into structural parts for prosthetic limbs, balancing durability and light weight.

-

Medical Robotics: Used in robotic surgical tools, they provide precision and durability for minimally invasive procedures.

Comparison Parameters Table

|

Parameter |

Our Titanium Plates |

Competitor A |

Competitor B |

|---|---|---|---|

|

Material |

Grade 2, Grade 5 (Ti-6Al-4V) |

Grade 2 Titanium |

Stainless Steel (316L) |

|

Tensile Strength |

550 MPa (Grade 2), 1000 MPa (Grade 5) |

550 MPa |

580 MPa |

|

Biocompatibility |

Excellent (no rejection risk) |

Excellent |

Good (higher rejection risk) |

|

Density |

4.5 g/cm³ |

4.5 g/cm³ |

8.0 g/cm³ |

|

Corrosion Resistance |

Excellent (bodily fluids, sterilization) |

Excellent |

Moderate (prone to pitting) |

|

Customization Options |

Extensive (sizes, shapes, finishes) |

Limited |

Moderate |

|

Manufacturing Process |

Vacuum arc melting, CNC machining, laser cutting |

Basic machining |

Standard fabrication |

|

Standards Compliance |

ASTM F67, ASTM F136 |

ASTM F67 |

ASTM F138 |

Company Advantages

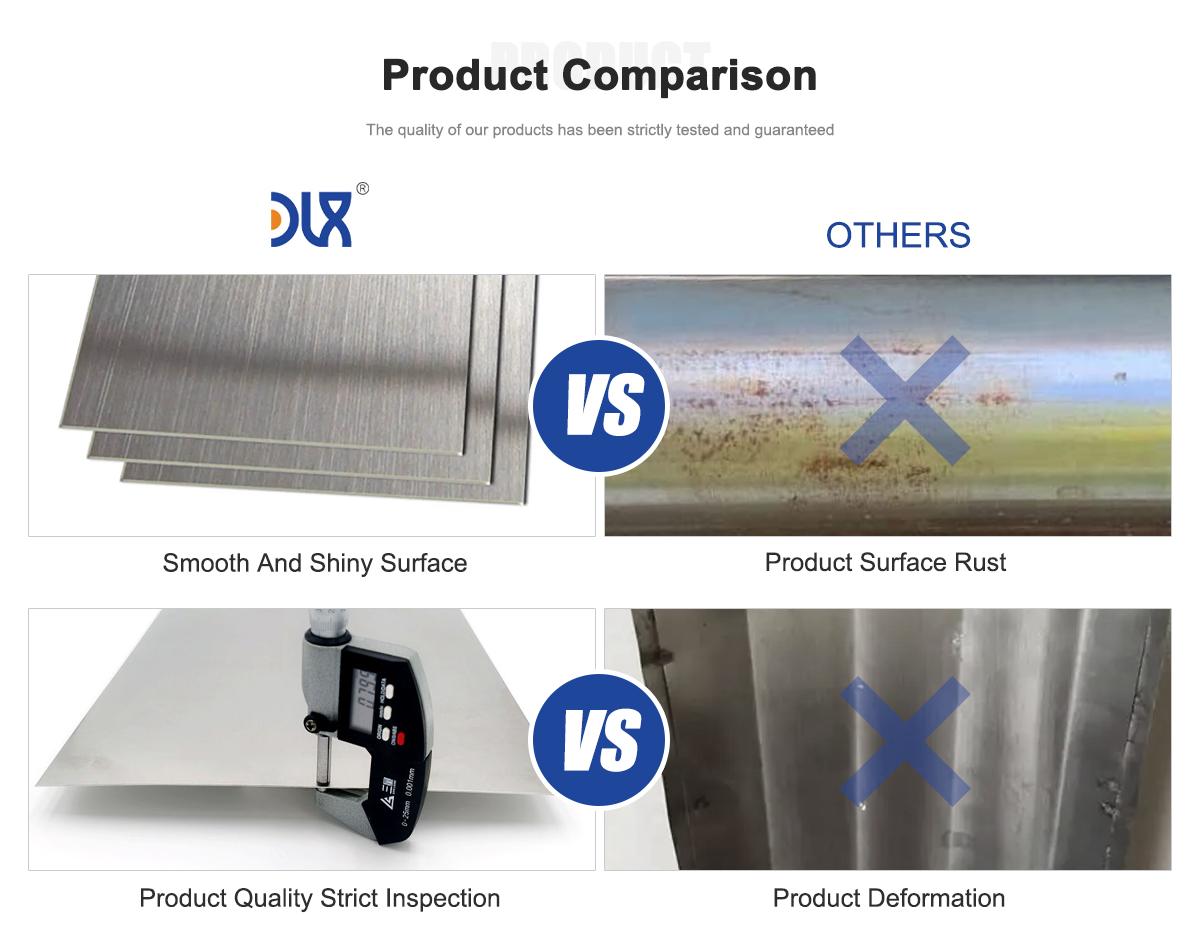

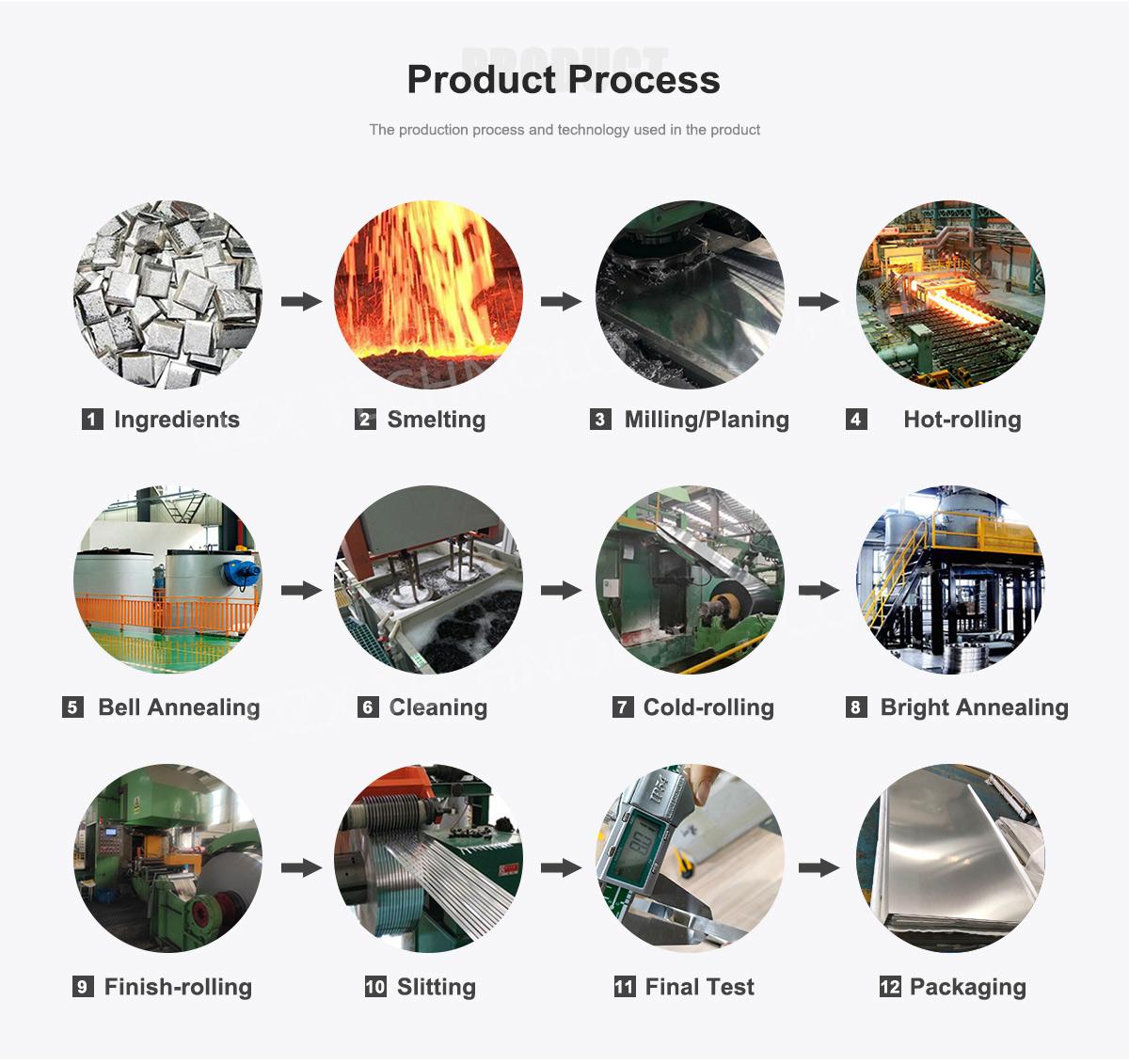

Our titanium plates for biomedical applications and surgical tools set the bar high. We use advanced vacuum arc melting, precision CNC machining, and laser cutting to produce plates with ultra-low impurities and flawless performance. Unlike others, we offer extensive customization, tailoring sizes, shapes, and finishes to match your exact implant or tool designs, ensuring safety and precision for medical applications.

Our supply chain is rock-solid, securing medical-grade titanium even in volatile markets, so your production stays on track. We’re pushing boundaries with additive manufacturing, creating patient-specific implants and complex tool designs with minimal waste, which keeps costs down and supports sustainability. Our plates are fully recyclable, and our production minimizes environmental impact, aligning with green medical trends.

With decades of expertise, we deliver plates that meet the strictest medical standards. Our R&D team is constantly innovating, developing processes for next-gen applications like smart implants and robotic surgery tools. Our global network ensures fast inventory access, and our plates’ durability means fewer revision surgeries or tool replacements, improving patient outcomes and saving costs. We’re the trusted partner for biomedical manufacturers who demand precision, safety, and reliability.

Why Choose Our Titanium Plates?

Our titanium plates are built to power biomedical applications and surgical tools, delivering biocompatibility, strength, and corrosion resistance for life-changing medical solutions. From implants to precision instruments, they ensure durability and patient safety with minimal complications. With cutting-edge manufacturing, a focus on sustainability, and a commitment to your success, we’re here to make your biomedical projects thrive in a competitive market.

For more details, pls directly contact us.

About Us:

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications.

For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

FAQs:

-

Why use titanium plates for biomedical applications?

They offer biocompatibility, strength, and corrosion resistance, ideal for implants and surgical tools. -

What titanium grades do you use?

Grade 2 for corrosion resistance and Grade 5 for higher strength in load-bearing applications. -

Do your plates meet medical standards?

Yes, they comply with ASTM F67 and ASTM F136 for medical-grade quality. -

Can your plates be customized?

Absolutely, we tailor sizes, thicknesses, and shapes to fit specific biomedical designs. -

How do your plates perform in the body?

They resist corrosion from bodily fluids and integrate well with tissue, minimizing rejection risks. -

Are your titanium plates recyclable?

Yes, titanium is fully recyclable, supporting sustainable medical manufacturing. -

What applications use your plates?

Orthopedic and dental implants, spinal and craniofacial reconstruction, surgical instruments, cardiovascular devices, prosthetics, and medical robotics. -

How do you ensure plate quality?

We use vacuum arc melting, precision machining, and strict testing to ensure defect-free, high-purity plates.