Bright surface Nickel 200 strip plays a critical role in resistance welding and electrical connector manufacturing. While often overlooked compared to more complex alloys, pure nickel continues to be a foundational material for industries where stable electrical performance and manufacturing reliability matter most. In practical production environments, these characteristics are not optional features; they are essential.

Nickel 200 is defined by its high purity. With a nickel content of at least 99.6%, it delivers consistent electrical and mechanical behavior. This consistency becomes particularly valuable in resistance welding applications. Welding relies on controlled electrical resistance to generate heat at precise locations. If material composition or surface condition fluctuates, weld quality becomes unpredictable. Bright surface Nickel 200 strip minimizes these risks by offering stable resistance and uniform contact surfaces.

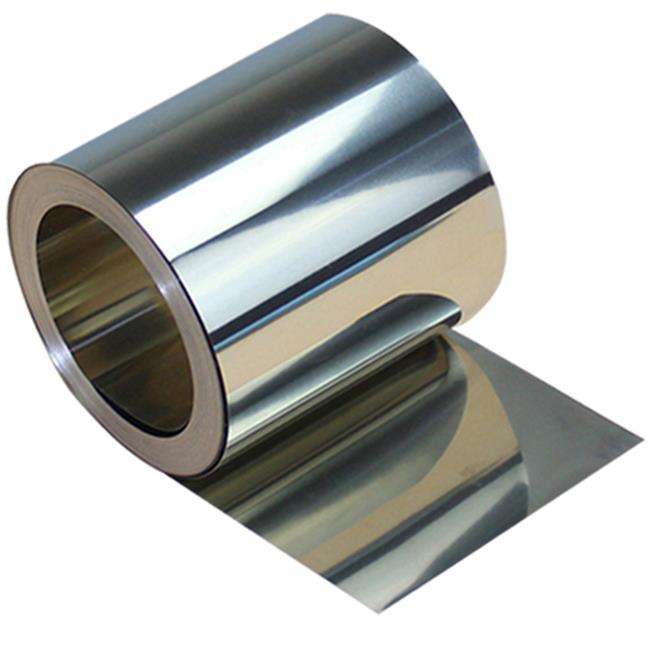

Surface quality is more than an aesthetic detail. In resistance welding, electrode contact directly influences heat generation and weld strength. A bright, smooth nickel surface ensures even current distribution and reduces localized overheating. This leads to cleaner welds, lower defect rates, and longer electrode life. For manufacturers operating high-volume welding lines, these benefits translate directly into cost savings and process stability.

Electrical connectors impose a different but equally demanding set of requirements. Connectors must maintain low contact resistance over long periods while withstanding mechanical stress, thermal cycling, and environmental exposure. Pure nickel’s oxidation resistance and stable conductivity help ensure reliable signal and power transmission. Bright surface finishing further improves contact consistency, reducing the risk of intermittent connections.

| Grade | Nickel (Ni)+ Cobalt (Co) | Copper (Cu) | Silicon (Si) | Manganese (Mn) | Carbon (C) | Magnesium (Mg) | Sulfur (S) | Phosphorus (P) | Iron (Fe) |

| 99.9% | ≤0.015 | ≤0.03 | ≤0.002 | ≤0.01 | ≤0.01 | ≤0.001 | ≤0.001 | ≤0.04 | |

| 99.6% | 0.1 | 0.1 | 0.05 | 0.1 | 0.1 | 0.005 | 0.002 | 0.1 |

Physical & Mechanical Properties

| Grades | N4/Ni201 | N6/Ni200 |

| Density | 8.9g/cm³ | 8.9g/cm³ |

| Melting Point | 1455°C | 1445-1470℃ |

| Coefficient of Thermal Expansion | 13.0µm/m·°C | 13.3×10⁻⁶/℃ |

| Thermal Conductivity | 10.1W/m·K | 90.7 W/m·K |

| Electrical Resistivity | 0.103×10⁻⁶Ω·/m (at 20℃) | |

| Electrical Conductivity | 14.6% IACS | |

| Tensile Strength | ≥450MPa | ≥450 MPa |

| Yield Strength | ≥200MPa | ≥150 MPa |

| Elongation at Break | ≥40% | ≥40% |

| Hardness | ≤150 |

For more details, pls directly contact us.

Manufacturability is another major advantage of Nickel 200 strip. Its excellent ductility allows it to be stamped, bent, and formed into complex connector geometries without cracking or excessive springback. This supports design flexibility and enables efficient mass production. In automated stamping and forming lines, material predictability helps maintain tight tolerances and reduce scrap.

Industry trends continue to support strong demand for high-quality nickel strip. Electrification, automation, and energy transition projects are driving growth in electrical connectors and welded assemblies. As systems become more compact and performance expectations rise, materials must deliver reliable behavior at smaller scales and higher current densities. Pure nickel remains a trusted choice in this evolving landscape.

Resistance welding applications are also expanding beyond traditional uses. Battery packs, energy storage systems, and advanced electronic modules rely heavily on welded connections. In these applications, joint integrity directly affects safety and performance. Bright surface Nickel 200 strip supports consistent weld quality, which is critical when scaling production.

From a supply perspective, the importance of material consistency cannot be overstated. Variations in thickness or surface condition can disrupt automated processes and require frequent parameter adjustments. In high-volume manufacturing, even minor inconsistencies can accumulate into significant losses. This is why experienced buyers focus not only on material grade but also on supplier capability.

From the DLX company point of view, supplying bright surface Nickel 200 strip is about more than meeting a specification. It is about delivering material that performs reliably in real production environments. Strict control over rolling, annealing, and surface finishing processes ensures that each coil maintains uniform thickness and surface quality.

Comparison of Typical Parameters

| Property / Feature | Bright Surface Nickel 200 Strip | General Nickel Strip |

|---|---|---|

| Nickel Content | ≥ 99.6% | Varies |

| Surface Condition | Smooth, bright, uniform | May be uneven |

| Electrical Conductivity | Stable and predictable | Composition dependent |

| Weldability | Excellent | Varies |

| Formability | Very good | Depends on alloy |

| Thickness Tolerance | Tight control | Supplier dependent |

| Corrosion Resistance | Excellent | Alloy dependent |

| Typical Applications | Resistance welding, connectors | General industrial |

Quality control is embedded throughout production. Monitoring surface cleanliness, dimensional accuracy, and mechanical properties helps ensure that the nickel strip behaves consistently during welding and forming. This approach reduces variability and supports stable downstream manufacturing.

Customization is another key strength. Resistance welding and connector designs vary widely depending on current levels, geometry, and assembly methods. DLX supports customized thicknesses, widths, and temper conditions to align material performance with specific application needs. This flexibility helps customers optimize both design and production efficiency.

Supply reliability also plays a critical role. Manufacturing schedules depend on predictable material availability. Delays or inconsistent deliveries can disrupt production planning and customer commitments. By maintaining stable capacity and disciplined logistics, DLX helps reduce these operational risks.

Bright surface Nickel 200 strip continues to prove its value across resistance welding and electrical connector applications. Its combination of purity, surface quality, and formability aligns naturally with the needs of modern electrical manufacturing. In practice, success in these industries is rarely driven by novelty alone. It is built on dependable materials that perform consistently day after day.

For more details, pls directly contact us.

About Us:

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications.

For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

What is Nickel 200 and why is it used in strip form?

Nickel 200 is commercially pure nickel with a minimum nickel content of 99.6%. In strip form, it offers excellent electrical conductivity, good ductility, and strong corrosion resistance, making it ideal for precision electrical and welding-related applications.What does “bright surface” mean for nickel strip?

A bright surface refers to a smooth, clean, and uniform finish achieved through controlled rolling and finishing processes. This surface quality improves electrical contact performance, welding consistency, and overall appearance in finished components.Why is Nickel 200 suitable for resistance welding?

Nickel 200 has stable electrical resistance and excellent weldability. Its consistent composition and surface quality allow predictable heat generation during resistance welding, resulting in strong, repeatable weld joints.How does Nickel 200 perform in electrical connectors?

Nickel 200 provides reliable conductivity, oxidation resistance, and mechanical stability. These properties help maintain low contact resistance and long service life in connectors exposed to current flow, heat, and environmental stress.Is bright surface nickel strip better for automated production lines?

Yes. A uniform surface reduces electrode wear, improves welding repeatability, and minimizes process variation. This is especially important in high-speed, automated manufacturing environments.Can Nickel 200 strip be easily formed or stamped?

Nickel 200 is highly ductile and can be stamped, bent, or formed into complex shapes without cracking. This makes it suitable for intricate connector designs and welded assemblies.What thickness ranges are commonly used?

Nickel 200 strip is available in a wide range of thicknesses, from thin gauges for delicate connectors to thicker strips for structural or high-current welding applications. Specifications are typically customized to customer needs.What should buyers look for when sourcing nickel strip for welding applications?

Key factors include surface consistency, thickness tolerance, purity level, and supplier quality control. These directly affect welding performance, yield rates, and long-term reliability.