Cold rolled Pure Nickel Strip with Ni99.6% purity has become an increasingly important material across modern energy technologies. As fuel cells and hydrogen electrolysis systems continue to gain traction worldwide, the role of high-purity conductive metals has moved from a niche requirement to a central design consideration. In these applications, material selection is not simply about meeting a specification on paper. It is about ensuring stable performance, long-term reliability, and manufacturing efficiency.

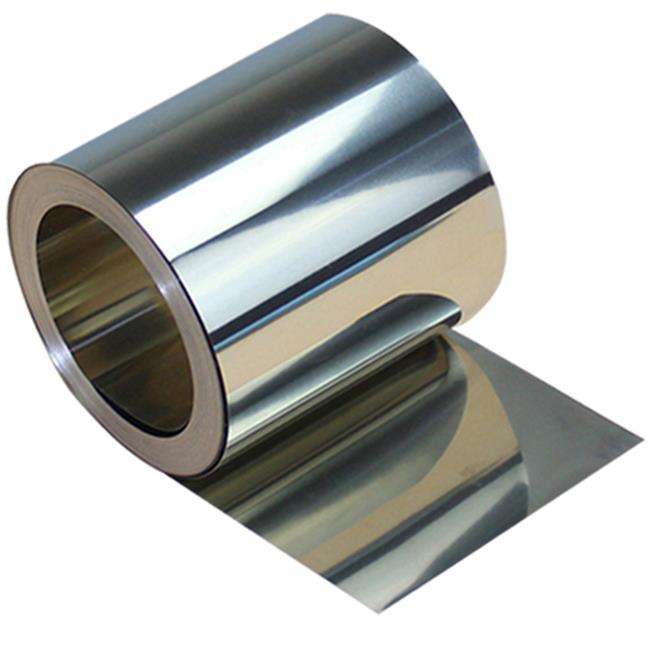

Pure nickel has always been valued for its unique balance of properties. It offers good electrical conductivity, excellent corrosion resistance, and strong mechanical workability. When processed through cold rolling, these advantages become even more pronounced. Cold rolling refines the strip’s dimensional accuracy, enhances surface quality, and improves consistency across coils. For industries where precision and repeatability drive success, these characteristics are more than desirable – they are necessary.

For more details, pls directly contact us.

In fuel cell systems, conductive materials play a direct role in overall efficiency. Connectors, tabs, and current-carrying components must transfer electricity with minimal losses while maintaining structural stability. High-purity Ni99.6% nickel strip provides predictable conductivity and resists oxidation under operating conditions. This helps engineers design assemblies that maintain performance over extended service periods without frequent maintenance or unexpected failures.

Hydrogen electrolysis systems present a similarly demanding environment. Materials are exposed to electrolytes, reactive gases, temperature variations, and continuous electrical loads. Under such conditions, impurities or inconsistent material structures can lead to degradation, unstable reactions, or reduced lifespan of critical components. High-purity cold rolled nickel strip minimizes these risks by delivering a stable chemical composition and uniform microstructure.

| Grade | Nickel (Ni)+ Cobalt (Co) | Copper (Cu) | Silicon (Si) | Manganese (Mn) | Carbon (C) | Magnesium (Mg) | Sulfur (S) | Phosphorus (P) | Iron (Fe) |

|

|

99.9% | ≤0.015 | ≤0.03 | ≤0.002 | ≤0.01 | ≤0.01 | ≤0.001 | ≤0.001 | ≤0.04 |

|

|

99.6% | 0.1 | 0.1 | 0.05 | 0.1 | 0.1 | 0.005 | 0.002 | 0.1 |

Physical & Mechanical Properties

| Grades | N4/Ni201 | N6/Ni200 |

| Density | 8.9g/cm³ | 8.9g/cm³ |

| Melting Point | 1455°C | 1445-1470℃ |

| Coefficient of Thermal Expansion | 13.0µm/m·°C | 13.3×10⁻⁶/℃ |

| Thermal Conductivity | 10.1W/m·K | 90.7 W/m·K |

| Electrical Resistivity | 0.103×10⁻⁶Ω·/m (at 20℃) | |

| Electrical Conductivity | 14.6% IACS | |

| Tensile Strength | ≥450MPa | ≥450 MPa |

| Yield Strength | ≥200MPa | ≥150 MPa |

| Elongation at Break | ≥40% | ≥40% |

| Hardness | ≤150 |

For more details, pls directly contact us.

Another practical advantage lies in corrosion behavior. Pure nickel demonstrates excellent resistance in many alkaline environments, making it highly compatible with electrochemical processes. This corrosion resistance directly influences equipment durability, reducing the likelihood of contamination, mechanical damage, or conductivity loss over time. In large-scale hydrogen projects, where system longevity significantly impacts economics, material stability becomes a strategic factor.

Cold rolling also improves manufacturability. Precision thickness control and smooth surfaces contribute to reliable stamping, forming, and welding operations. In automated production lines, even small variations in strip dimensions can disrupt welding parameters or cause assembly defects. Uniform cold rolled nickel strip supports stable process windows, improving yield rates and reducing production downtime.

Weldability is particularly important. Fuel cell components, battery connections, and electrolysis assemblies frequently rely on resistance welding or spot welding techniques. Pure nickel’s inherent weldability, combined with the clean surface characteristics of cold rolled strip, helps ensure strong, repeatable joints. This is essential for both mechanical integrity and electrical continuity.

Industry trends further reinforce the relevance of high-purity nickel materials. Global investment in hydrogen energy, renewable storage, and electrification technologies continues to grow. As these industries scale, the demand for materials that combine performance with process compatibility rises accordingly. Engineers and procurement teams are increasingly focused on materials that not only meet functional requirements but also simplify manufacturing and quality control.

Within this evolving landscape, supplier capability becomes a decisive factor. Industrial users are not merely purchasing metal strip; they are integrating a critical input into highly sensitive systems. Variations in purity, tolerance, or surface condition can cascade into costly operational issues. Stable sourcing therefore carries both technical and commercial significance.

| Property / Feature | Cold Rolled Pure Nickel Strip (Ni99.6%) | General Nickel Strip (Lower Purity) |

|---|---|---|

| Nickel Purity | ≥ 99.6% | Varies |

| Surface Condition | Smooth, uniform | May vary |

| Thickness Tolerance | Tight control | Less consistent |

| Electrical Conductivity | Stable, predictable | May fluctuate |

| Corrosion Resistance | Excellent | Dependent on composition |

| Weldability | Excellent | Varies |

| Formability | Very good | Composition dependent |

| Typical Industries | Fuel cell, hydrogen, battery, electronics | General industrial uses |

From the DLX company perspective, the priority is clear: deliver cold rolled pure nickel strip that behaves consistently across real-world production environments. Instead of emphasizing theoretical advantages, the focus is placed on process control, material uniformity, and practical reliability. Strict control over raw material selection and rolling parameters ensures that Ni99.6% purity is not just a nominal figure but a dependable characteristic.

Dimensional precision is another core consideration. Fuel cell and hydrogen system manufacturers often require tight thickness tolerances to maintain predictable electrical and thermal behavior. By maintaining disciplined rolling and inspection procedures, DLX supports these requirements while helping customers reduce downstream variability.

Customization also plays a central role. Energy system designs vary widely in geometry, current density, and assembly methods. Standardized strip dimensions may not always fit specialized production lines. Flexible manufacturing capabilities allow DLX to provide tailored thicknesses, widths, and temper conditions aligned with specific engineering and procurement needs.

Reliability extends beyond the material itself. Consistent delivery schedules, clear technical communication, and stable production capacity are equally important for industrial customers. In fast-moving sectors like hydrogen and advanced energy systems, material delays can disrupt entire project timelines. A dependable supply partner reduces operational risk while supporting long-term planning.

Cold rolled Ni99.6% pure nickel strip continues to prove its value by offering a combination of conductivity, corrosion resistance, and manufacturing compatibility. As fuel cell and hydrogen electrolysis technologies expand, materials that deliver predictable behavior and stable quality will remain essential. In practice, performance is rarely defined by a single property. It emerges from the interaction of chemistry, processing, and consistency.

For more details, pls directly contact us.

About Us:

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications.

For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

-

What does Ni99.6% mean in pure nickel strip?

Ni99.6% refers to the nickel purity level, indicating that the material contains a minimum of 99.6% nickel. This high purity ensures stable electrical conductivity, excellent corrosion resistance, and predictable electrochemical behavior, all of which are essential for fuel cell and hydrogen electrolysis applications. -

Why is cold rolled nickel strip preferred in energy systems?

Cold rolling improves dimensional accuracy, surface finish, and mechanical consistency. For precision-driven industries like fuel cells and hydrogen systems, tighter tolerances and smoother surfaces translate into better welding performance, more reliable electrical contact, and improved assembly efficiency. -

Is pure nickel strip suitable for corrosive environments?

Yes. High-purity nickel exhibits strong resistance to many corrosive media, particularly alkaline environments. This makes Ni99.6% nickel strip a practical choice for components exposed to electrolytes, humidity, and reactive gases commonly found in electrochemical systems. -

How does pure nickel strip perform electrically?

Pure nickel offers good electrical conductivity combined with excellent oxidation resistance. In fuel cells and electrolysis systems, this balance supports efficient current transfer while maintaining long-term stability under operating conditions. -

What are typical applications of Ni99.6% nickel strip?

Common uses include fuel cell connectors, hydrogen electrolysis electrodes, battery tabs, current collectors, lead frames, precision stamping parts, and spot-welded assemblies. The material is widely selected wherever conductivity, formability, and corrosion resistance are required simultaneously. -

Can cold rolled nickel strip be spot welded easily?

Yes. Pure nickel strip is well known for its excellent weldability. Consistent thickness and clean surfaces achieved through cold rolling enhance weld quality and reduce defects, which is especially important in automated production lines. -

What thickness range is normally available?

Cold rolled pure nickel strip can be produced in a wide range of thicknesses, from ultra-thin foil for micro components to heavier gauges for structural or high-current applications. Exact specifications are typically customized based on forming and electrical requirements. -

What factors matter most when sourcing nickel strip for hydrogen systems?

Key considerations include purity level, thickness tolerance, surface cleanliness, mechanical uniformity, and supplier reliability. Inconsistent material properties can directly impact electrochemical efficiency and equipment lifespan.