High conductivity Pure Nickel Strip has become a core material across rapidly expanding industries such as electric vehicles and renewable energy systems. These sectors share a common requirement: reliable electrical performance under demanding mechanical and environmental conditions. While technology often receives most of the attention, material selection plays an equally decisive role in determining whether a system performs consistently over time.

Pure nickel strip stands out because it delivers a rare balance of properties. Electrical conductivity is the first and most obvious advantage. In EV battery modules and renewable energy equipment, conductive materials must transfer current efficiently while minimizing energy losses. Even small resistance variations can lead to unwanted heat generation, reduced efficiency, or localized stress. High purity pure nickel strip provides predictable conductivity, helping engineers design stable electrical pathways.

In electric vehicle battery systems, conductive strip materials are everywhere. Battery tabs, connectors, busbars, and welded joints all depend on metals that behave consistently. Unlike some alloyed alternatives, pure nickel offers a stable electrical profile. This stability supports uniform current distribution, which is crucial for thermal management and overall battery safety. In large battery packs, reliability is rarely about a single connection; it is about maintaining consistency across thousands of joints.

For more details, pls directly contact us.

Weldability is another reason pure nickel strip is widely adopted. Resistance welding and spot welding processes depend heavily on material properties. If composition or surface condition varies, weld quality can become unpredictable. Pure nickel’s consistent behavior under electrical and thermal loads allows manufacturers to maintain stable welding parameters. This reduces the likelihood of weak joints, excessive spatter, or inconsistent fusion.

Mechanical characteristics further enhance its practicality. Pure nickel strip is known for excellent ductility and formability. EV battery components and renewable energy assemblies often involve tight bends, thin sections, and precision stamping. Materials with limited workability introduce cracking risks and higher rejection rates. Pure nickel’s adaptability supports high-speed forming processes, helping manufacturers maintain productivity while protecting component integrity.

| Grade | Nickel (Ni)+ Cobalt (Co) | Copper (Cu) | Silicon (Si) | Manganese (Mn) | Carbon (C) | Magnesium (Mg) | Sulfur (S) | Phosphorus (P) | Iron (Fe) |

| 99.9% | ≤0.015 | ≤0.03 | ≤0.002 | ≤0.01 | ≤0.01 | ≤0.001 | ≤0.001 | ≤0.04 | |

| 99.6% | 0.1 | 0.1 | 0.05 | 0.1 | 0.1 | 0.005 | 0.002 | 0.1 |

Physical & Mechanical Properties

| Grades | N4/Ni201 | N6/Ni200 |

| Density | 8.9g/cm³ | 8.9g/cm³ |

| Melting Point | 1455°C | 1445-1470℃ |

| Coefficient of Thermal Expansion | 13.0µm/m·°C | 13.3×10⁻⁶/℃ |

| Thermal Conductivity | 10.1W/m·K | 90.7 W/m·K |

| Electrical Resistivity | 0.103×10⁻⁶Ω·/m (at 20℃) | |

| Electrical Conductivity | 14.6% IACS | |

| Tensile Strength | ≥450MPa | ≥450 MPa |

| Yield Strength | ≥200MPa | ≥150 MPa |

| Elongation at Break | ≥40% | ≥40% |

| Hardness | ≤150 |

For more details, pls directly contact us.

Corrosion resistance also plays a critical role, particularly in renewable energy applications. Energy systems may be exposed to moisture, temperature cycling, and chemical influences. Materials that degrade over time compromise both conductivity and structural stability. Pure nickel’s resistance to many corrosive environments helps ensure long-term performance, reducing maintenance demands and component replacement frequency.

Industry trends continue to drive demand for reliable conductive materials. Electrification is accelerating globally, with EV production scaling across multiple markets. Renewable energy infrastructure is expanding alongside energy storage technologies. As production volumes increase, manufacturers face growing pressure to maintain quality, reduce waste, and stabilize costs. Under these conditions, material consistency becomes a strategic advantage rather than a simple technical preference.

In high-volume automated manufacturing, variations in strip thickness or surface condition can have outsized effects. Welding parameters may drift, forming tools may behave unpredictably, and equipment wear may increase. Reliable pure nickel strip helps maintain stable process windows. This improves yield rates, reduces downtime, and simplifies quality control. For production engineers, predictable materials are essential for maintaining efficiency.

From the DLX company perspective, supplying high conductivity pure nickel strip involves far more than providing a nominal material grade. The focus is on delivering strip that performs reliably in real manufacturing environments. Purity control, rolling precision, and surface finishing are managed carefully because downstream applications are highly sensitive to deviation.

Comparison of Typical Parameters

| Property / Feature | High Conductivity Pure Nickel Strip | General Nickel-Based Strip |

|---|---|---|

| Nickel Purity | Very high (commercially pure) | Composition varies |

| Electrical Conductivity | Stable and predictable | Alloy dependent |

| Surface Quality | Controlled, uniform | Supplier dependent |

| Weldability | Excellent | Varies |

| Formability | Very good | Composition dependent |

| Thickness Tolerance | Tight control possible | May vary |

| Corrosion Resistance | Excellent in many environments | Alloy dependent |

| Typical Industries | EV batteries, energy storage, renewable systems | Broader industrial uses |

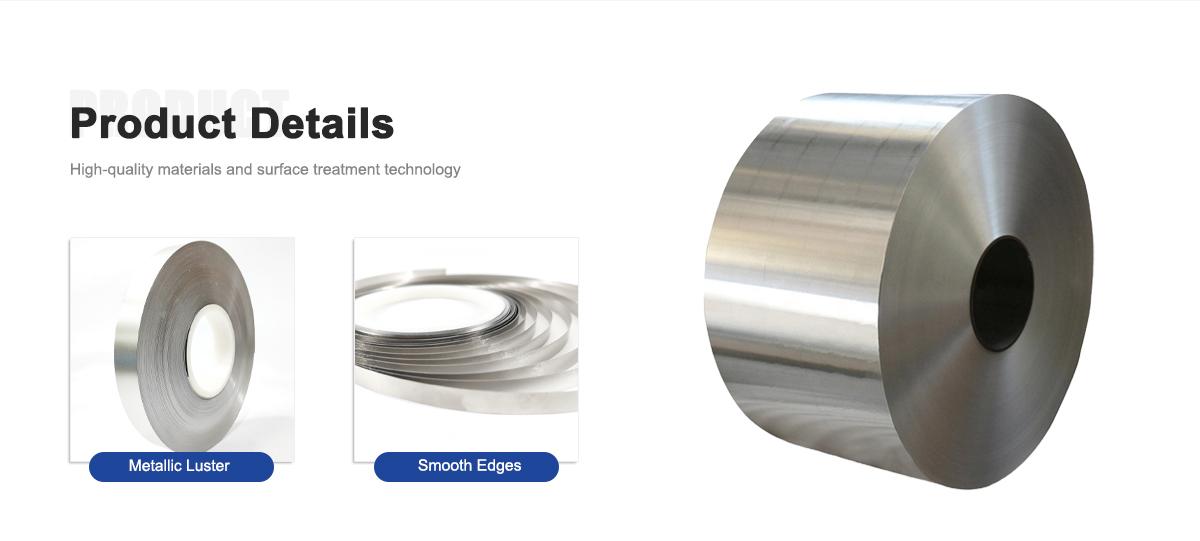

Dimensional accuracy is a particularly important factor. EV battery designs and renewable energy components often require tight tolerances to maintain predictable electrical and mechanical behavior. Variations that might be acceptable in general industrial contexts can create challenges in precision assemblies. Controlled production and inspection processes help ensure uniform thickness and consistent mechanical properties.

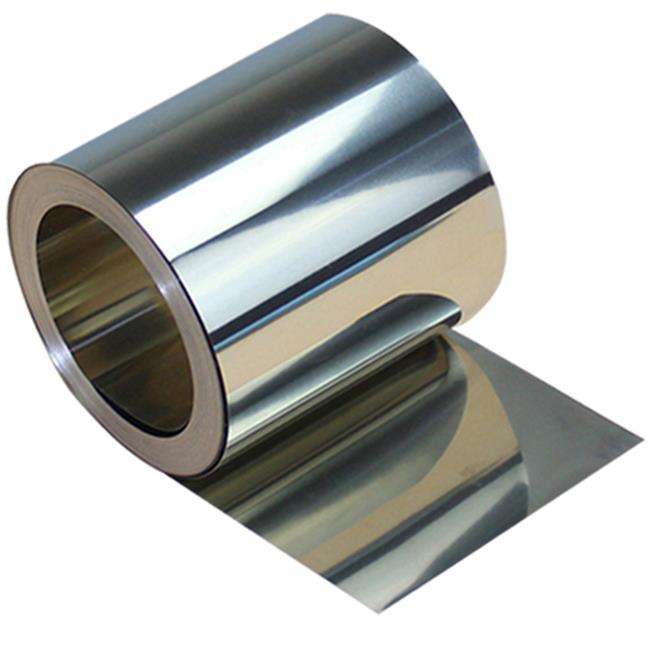

Surface quality is equally significant. Bright, clean surfaces support stable welding and low contact resistance. Irregular or contaminated surfaces can introduce variability and increase defect risks. Careful handling and finishing procedures help preserve strip integrity from production through shipment.

Customization capability is another key consideration. Battery systems and energy equipment vary widely in geometry and performance requirements. Flexible manufacturing allows tailored thicknesses, widths, and temper conditions aligned with specific customer needs. This adaptability supports design optimization and procurement efficiency.

Global competition in conductive materials is intense, with buyers evaluating suppliers based on quality, reliability, and long-term stability. In this environment, consistent performance and clear technical communication become decisive advantages. Industrial customers value partners who understand production realities rather than focusing solely on theoretical specifications.

Supply reliability also plays a strategic role. EV and renewable energy projects often operate under strict timelines. Material delays can disrupt production schedules and project planning. Maintaining disciplined capacity and logistics coordination helps reduce these risks, supporting stable customer operations.

High conductivity pure nickel strip continues to demonstrate its value as electrification and renewable energy technologies expand. Its combination of conductivity, weldability, formability, and corrosion resistance aligns naturally with the needs of modern energy systems. In practice, long-term performance depends not only on advanced design but also on dependable materials that behave consistently day after day.

For more details, pls directly contact us.

About Us:

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications.

For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing: