Customized thickness Pure Nickel Strip under GB/T N6 specifications has become increasingly important in modern industrial procurement and OEM production. While pure nickel itself is a well-established material, the growing demand for dimensional precision and application-specific performance has shifted attention toward customization rather than simple material availability. In today’s manufacturing environment, standardized products are not always enough. Engineers and procurement teams often need materials tailored to exact functional and processing requirements.

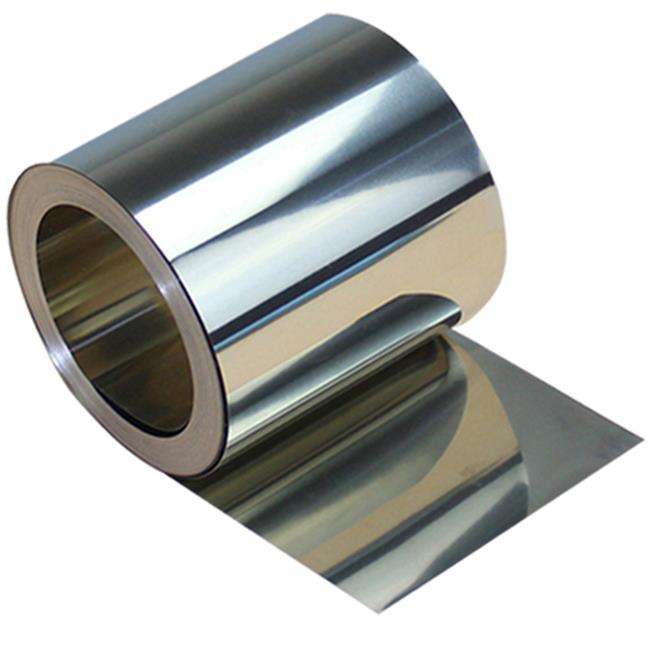

Pure nickel strip is valued for its high nickel content, stable electrical conductivity, excellent ductility, and strong corrosion resistance. These core properties already make it suitable for a wide range of applications, from battery systems and electronic components to chemical equipment and precision assemblies. However, thickness plays a decisive role in determining how these properties translate into real-world performance.

For more details, pls directly contact us.

Electrical behavior, for example, is closely linked to geometry. In conductive components, even small changes in cross-sectional area influence resistance and heat generation. OEM manufacturers designing battery tabs, connectors, or current-carrying elements cannot rely on approximate dimensions. Customized thickness ensures that electrical characteristics align with design expectations, supporting efficiency and long-term reliability.

Mechanical performance is equally sensitive to thickness variation. Forming operations, bending radii, and structural behavior all depend on precise dimensional control. Pure nickel’s inherent ductility allows it to be formed into complex shapes, but predictable forming results require uniform thickness across coils and batches. Inconsistent strip dimensions can introduce cracking risks, uneven deformation, or tool wear issues in high-speed production lines.

Welding applications further highlight the importance of thickness control. Resistance and spot welding processes rely on consistent heat generation, which is directly affected by material thickness and electrical resistance. Variations force operators to frequently adjust parameters, increasing production complexity and defect risks. Customized thickness pure nickel strip stabilizes these processes by delivering repeatable material behavior.

| Grade | Nickel (Ni)+ Cobalt (Co) | Copper (Cu) | Silicon (Si) | Manganese (Mn) | Carbon (C) | Magnesium (Mg) | Sulfur (S) | Phosphorus (P) | Iron (Fe) |

|

|

99.9% | ≤0.015 | ≤0.03 | ≤0.002 | ≤0.01 | ≤0.01 | ≤0.001 | ≤0.001 | ≤0.04 |

|

|

99.6% | 0.1 | 0.1 | 0.05 | 0.1 | 0.1 | 0.005 | 0.002 | 0.1 |

Physical & Mechanical Properties

| Grades | N4/Ni201 | N6/Ni200 |

| Density | 8.9g/cm³ | 8.9g/cm³ |

| Melting Point | 1455°C | 1445-1470℃ |

| Coefficient of Thermal Expansion | 13.0µm/m·°C | 13.3×10⁻⁶/℃ |

| Thermal Conductivity | 10.1W/m·K | 90.7 W/m·K |

| Electrical Resistivity | 0.103×10⁻⁶Ω·/m (at 20℃) | |

| Electrical Conductivity | 14.6% IACS | |

| Tensile Strength | ≥450MPa | ≥450 MPa |

| Yield Strength | ≥200MPa | ≥150 MPa |

| Elongation at Break | ≥40% | ≥40% |

| Hardness | ≤150 |

For more details, pls directly contact us.

Industry trends reinforce why customized nickel strip is gaining attention. Across sectors such as energy storage, electronics, and advanced equipment manufacturing, components are becoming smaller, more integrated, and more performance-sensitive. Tolerances that once seemed strict are now considered standard. Manufacturers increasingly prefer suppliers who can adapt materials to design and process requirements rather than offering only fixed specifications.

Industrial procurement strategies are also evolving. Cost control remains important, but buyers are paying closer attention to hidden operational costs associated with material inconsistency. Production interruptions, quality issues, and increased scrap often outweigh small differences in material price. Reliable, application-ready materials reduce these risks and support stable long-term manufacturing economics.

From the DLX company perspective, supplying customized thickness GB/T N6 pure nickel strip is not treated as a simple transaction. The emphasis is placed on understanding how customers actually use the material. Instead of focusing solely on nominal purity or standard dimensions, attention is directed toward dimensional precision, mechanical consistency, and surface quality — the factors that most directly affect production outcomes.

Process control is central to this approach. Thickness customization requires disciplined rolling, annealing, and inspection procedures. Achieving tight tolerances consistently across production runs is not merely a technical capability; it is a reflection of manufacturing stability. Reliable thickness control helps customers maintain predictable forming, stamping, and welding conditions.

Surface quality is another critical factor. Pure nickel strip is often used in applications involving electrical contact or welding. Clean, uniform surfaces reduce contact resistance and improve joining reliability. Variations in surface condition can disrupt automated processes and compromise performance. Controlled finishing and handling procedures help ensure consistent strip quality.

Customization flexibility also supports design optimization. OEM manufacturers frequently refine component geometries to balance performance, weight, and cost. Access to tailored strip thicknesses allows engineers to adjust designs without being constrained by material limitations. This adaptability contributes to more efficient product development cycles.

| Property / Feature | Customized Thickness GB/T N6 Pure Nickel Strip | Standard Nickel Strip |

|---|---|---|

| Nickel Purity | High (commercially pure) | Varies |

| Thickness Flexibility | Fully customizable | Limited options |

| Thickness Tolerance | Tight control possible | Supplier dependent |

| Electrical Conductivity | Stable and predictable | Composition dependent |

| Weldability | Excellent | Varies |

| Formability | Very good | Alloy dependent |

| Surface Condition | Controlled, uniform | May vary |

| Typical Applications | OEM, batteries, electronics, precision parts | General industrial |

Global competition among nickel strip suppliers is intense. Buyers can source materials from multiple regions, each offering different combinations of price, lead time, and quality. In this environment, consistency and reliability often become decisive differentiators. Industrial customers value suppliers capable of delivering stable material properties over time rather than simply meeting minimum specifications.

Supply stability is particularly important for OEM production. Manufacturing schedules, inventory planning, and customer commitments depend on predictable material availability. Disruptions in supply chains can have cascading effects across operations. Maintaining disciplined production capacity and logistics coordination helps reduce these uncertainties.

Customized thickness GB/T N6 pure nickel strip continues to prove its relevance because it aligns with fundamental industrial priorities: performance predictability, process compatibility, and long-term reliability. In practice, successful OEM production relies not only on advanced equipment and design but also on materials that behave consistently across millions of parts.

Pure nickel strip’s combination of conductivity, ductility, and corrosion resistance already makes it a versatile engineering material. When paired with accurate thickness customization, it becomes an even more powerful solution for modern industrial manufacturing. As industries continue moving toward higher precision and tighter tolerances, the role of customized materials will only grow.

For more details, pls directly contact us.

About Us:

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications.

For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

-

What is GB/T N6 pure nickel strip?

GB/T N6 is a Chinese standard designation for commercially pure nickel with high nickel content, typically ≥ 99.6%. It is widely recognized for its stable electrical conductivity, excellent corrosion resistance, and good mechanical workability, making it suitable for demanding industrial and OEM applications. -

Why is customized thickness important for nickel strip?

Different industries and production processes require specific thickness ranges to balance electrical performance, mechanical strength, and forming behavior. Customized thickness allows engineers and procurement teams to match the material precisely with design requirements and manufacturing conditions. -

How does pure nickel strip perform electrically?

High purity nickel strip provides consistent and predictable conductivity. This is essential in applications involving current transfer, resistance welding, battery connections, and precision electronic components where resistance stability directly impacts efficiency and reliability. -

Is GB/T N6 nickel strip suitable for welding applications?

Yes. Pure nickel strip is well known for its excellent weldability, especially in resistance and spot welding. Uniform thickness and clean surfaces help ensure repeatable weld quality and minimize defects in automated production lines. -

What industries commonly use pure nickel strip?

Typical industries include battery manufacturing, electronics, electrical connectors, chemical processing, precision instruments, heating elements, and various OEM assemblies. Its versatility comes from the combination of conductivity, ductility, and corrosion resistance. -

How does thickness tolerance affect OEM production?

In high-volume OEM production, thickness variation can disrupt forming operations and welding parameters. Tight tolerance control supports process stability, reduces scrap, and ensures consistent product performance across batches. -

Can mechanical properties be adjusted along with thickness?

Yes. Depending on application needs, pure nickel strip can be supplied in different tempers such as soft annealed or cold rolled conditions. These adjustments influence hardness, formability, and strength characteristics. -

What should buyers consider when sourcing customized nickel strip?

Buyers should evaluate material purity, dimensional accuracy, surface quality, consistency, and supplier reliability. A dependable supplier directly supports production efficiency and reduces operational risks.