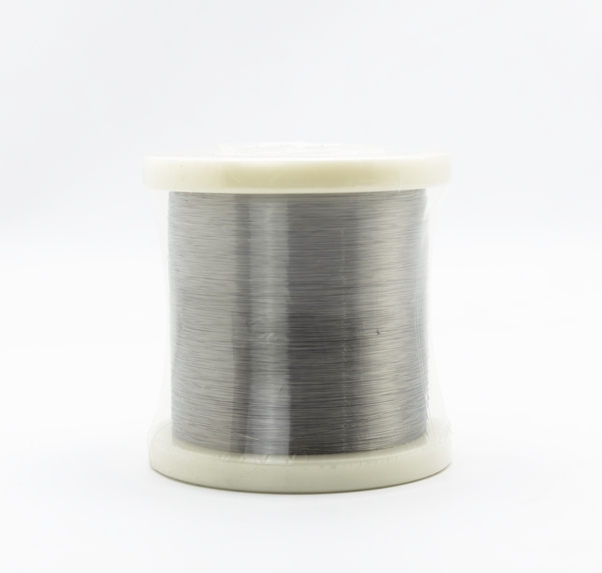

ASTM B160 Pure Nickel Wire remains one of the most trusted materials in electrochemical systems, hydrogen production equipment, and OEM industrial manufacturing. At DLX, we supply high-purity Nickel 200 and Nickel 201 wire directly from our factory, ensuring stable quality and long-term reliability for industrial customers worldwide.

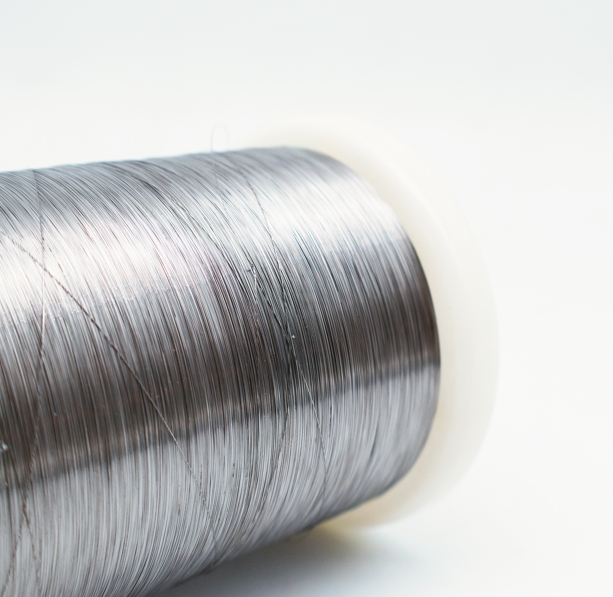

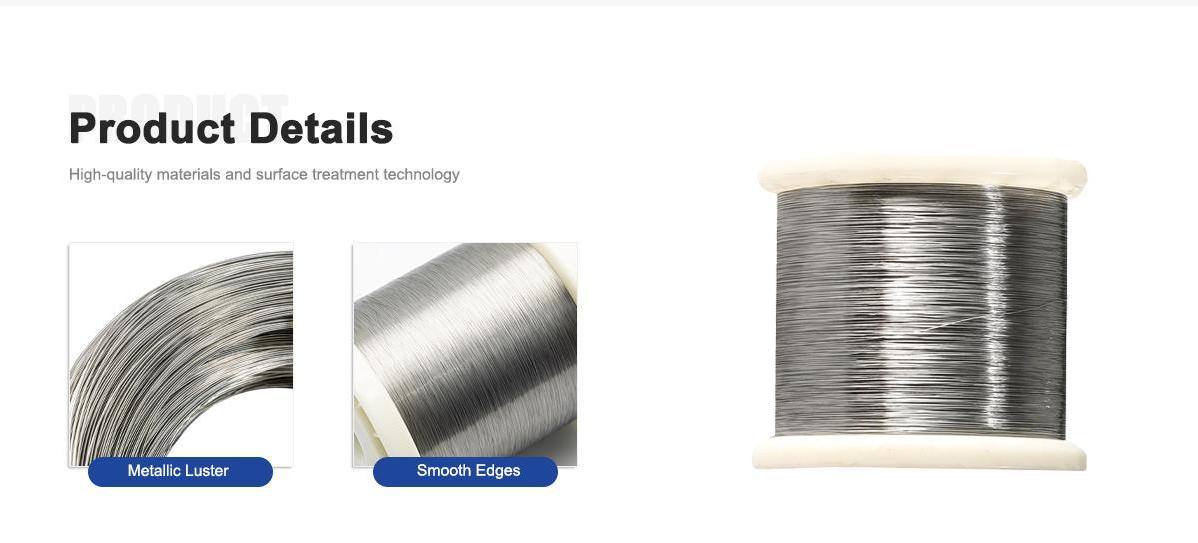

Pure nickel wire may appear simple compared to complex superalloys, but in electrochemical and hydrogen environments, simplicity often means reliability. The controlled chemical composition, especially high nickel purity and low impurity levels, ensures predictable performance under corrosive and high-temperature conditions.

For electrochemical and hydrogen applications, consistency matters more than marketing claims. That is where DLX focuses its strength.

For more details, pls directly contact us.

Electrochemical environments are demanding. Materials must resist corrosion while maintaining stable electrical conductivity. ASTM B160 pure nickel wire performs exceptionally well in alkaline solutions, which are common in electrolysis and hydrogen generation systems.

Nickel forms a stable protective oxide layer in many environments, helping extend service life without compromising conductivity. This balance between chemical resistance and electrical performance makes pure nickel wire a core material in electrochemical engineering.

For higher temperature exposure, Nickel 201 provides added protection due to its low carbon content. This reduces the risk of structural degradation during prolonged operation.

| Grades | N4/Ni201 | N6/Ni200 |

| Density | 8.9g/cm³ | 8.9g/cm³ |

| Melting Point | 1455°C | 1445-1470℃ |

| Coefficient of Thermal Expansion | 13.0µm/m·°C | 13.3×10⁻⁶/℃ |

| Thermal Conductivity | 10.1W/m·K | 90.7 W/m·K |

| Electrical Resistivity | 0.103×10⁻⁶Ω·/m (at 20℃) | |

| Electrical Conductivity | 14.6% IACS | |

| Tensile Strength | ≥450MPa | ≥450 MPa |

| Yield Strength | ≥200MPa | ≥150 MPa |

| Elongation at Break | ≥40% | ≥40% |

| Hardness | ≤150 |

For more details, pls directly contact us.

The global push toward hydrogen energy has significantly increased demand for pure nickel materials. In alkaline water electrolysis systems, pure nickel wire is used in electrodes, connectors, support structures, and current-carrying components.

Nickel’s resistance to caustic environments makes it especially suitable for long-term hydrogen production equipment. It maintains dimensional stability and electrical integrity even under continuous operation.

Hydrogen equipment manufacturers require materials that meet international standards and allow easy qualification. ASTM B160 compliance simplifies procurement and technical documentation.

At DLX, we work closely with hydrogen equipment OEM customers to ensure wire diameter, temper, and surface condition match their production requirements.

ASTM B160 Pure Nickel Wire – Technical Parameter Comparison

| Parameter | Nickel 200 (N02200) | Nickel 201 (N02201) |

|---|---|---|

| Nickel Content | ≥ 99.6% | ≥ 99.6% |

| Carbon Content | ≤ 0.15% | ≤ 0.02% |

| Standard | ASTM B160 | ASTM B160 |

| Equivalent DIN | 2.4060 | 2.4066 |

| Equivalent JIS | NW2200 | NW2201 |

| Density | 8.89 g/cm³ | 8.89 g/cm³ |

| Electrical Resistivity | ~0.096 μΩ·m | ~0.096 μΩ·m |

| Max Recommended Temp | ~600°C | ~800°C |

| Corrosion Resistance | Excellent in alkali | Excellent in alkali |

In electrochemical reactors and plating systems, pure nickel wire serves as anodes, connectors, and conductive components. Its predictable dissolution rate supports stable plating bath chemistry, which improves coating quality.

Compared to complex alloy materials, pure nickel reduces contamination risk in electrochemical processes. This is critical for industries that demand high coating uniformity or chemical purity.

DLX pure nickel wire is produced with strict surface control to minimize contamination and ensure consistent performance in electrochemical systems.

OEM Industrial Applications

Beyond hydrogen and electrochemical systems, ASTM B160 pure nickel wire is widely used in OEM industrial manufacturing. Applications include sensors, heating elements, furnace components, battery connectors, and electrical assemblies.

OEM manufacturers prefer pure nickel wire because it is easy to weld, bend, and form. Its ductility and stable mechanical properties simplify integration into automated production lines.

By offering customized diameters and packaging solutions, DLX supports OEM customers in optimizing material handling and reducing waste.

Industry Trends and Market Demand

The demand for ASTM B160 pure nickel wire is growing alongside investments in renewable energy, hydrogen infrastructure, and industrial modernization.

Electrochemical technologies are expanding beyond traditional plating into energy storage and environmental engineering. This shift increases the need for corrosion-resistant conductive materials.

At the same time, industrial customers are consolidating supplier bases and seeking long-term partnerships with reliable manufacturers. Quality consistency and traceability are becoming more important than lowest price.

DLX is positioned to meet these evolving expectations with controlled production processes and global supply capability.

DLX Compared with Typical Market Suppliers

In the open market, pure nickel wire is often traded through intermediaries. While pricing may appear competitive, batch consistency and traceability can vary.

DLX operates as a manufacturer with direct control over raw materials, melting, drawing, and finishing processes. Each production batch undergoes chemical composition testing and dimensional inspection before shipment.

This controlled approach reduces variability and supports critical applications such as hydrogen production and electrochemical systems where performance reliability is essential.

We also provide technical communication tailored to engineers and procurement teams, helping them select the correct grade—Nickel 200 or Nickel 201—based on operating conditions.

Why Choose DLX as Your ASTM B160 Pure Nickel Wire Supplier

DLX focuses on long-term industrial cooperation. Our factory-direct model offers stable pricing, consistent production scheduling, and flexible MOQ to support both project-based and continuous supply needs.

We provide full material certification, export-compliant packaging, and responsive support for international customers. Whether for hydrogen systems, electrochemical equipment, or OEM industrial manufacturing, DLX delivers pure nickel wire that meets real-world performance expectations.

By combining material expertise with practical production understanding, we help customers reduce risk, improve efficiency, and secure reliable supply chains.

Long-Term Value in Electrochemical and Energy Projects

Electrochemical and hydrogen systems often operate continuously for extended periods. Material failure can result in costly downtime and safety risks.

Choosing ASTM B160 pure nickel wire from a controlled manufacturer ensures predictable behavior and long service life. DLX supports customers not just with material, but with consistent partnership.

Pure nickel wire remains a foundational material in modern industry. With the right quality control and application understanding, it continues to play a central role in energy transition and advanced industrial engineering.

For more details, pls directly contact us.

About Us:

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications.

For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

1. What is ASTM B160 pure nickel wire?

ASTM B160 pure nickel wire refers to commercially pure wrought nickel manufactured according to ASTM B160 standard specifications. It typically includes Nickel 200 (UNS N02200) and Nickel 201 (UNS N02201), both containing a minimum of 99.6% nickel.

2. What is the difference between Nickel 200 and Nickel 201 under ASTM B160?

The main difference is carbon content. Nickel 200 has higher allowable carbon (≤0.15%), while Nickel 201 has low carbon (≤0.02%), making it more suitable for high-temperature applications where carbon embrittlement must be avoided.

3. Why is pure nickel wire widely used in electrochemical applications?

Pure nickel wire offers excellent resistance to alkaline corrosion, stable conductivity, and predictable electrochemical behavior. It performs reliably in electrolysis systems, plating equipment, and electrochemical reactors.

4. Is ASTM B160 nickel wire suitable for hydrogen production systems?

Yes. Pure nickel wire is widely used in alkaline hydrogen electrolysis systems due to its chemical stability and resistance to caustic environments.

5. What industries typically use ASTM B160 pure nickel wire?

Industries include hydrogen energy, electroplating, chemical processing, battery manufacturing, furnace engineering, electronics, and OEM industrial equipment production.

6. What sizes and conditions can DLX supply?

DLX supplies pure nickel wire in various diameters, including fine wire and heavy industrial wire. Conditions include annealed, bright annealed, and hard-drawn, customized according to application requirements.

7. What international equivalents correspond to ASTM B160?

Equivalent grades include UNS N02200 / N02201, DIN 2.4060 / 2.4066, and JIS NW2200 / NW2201, allowing global engineering compatibility.

8. Why choose a direct manufacturer for pure nickel wire supply?

A direct manufacturer ensures consistent chemical composition, controlled production processes, stable batch quality, and better long-term pricing compared to trading intermediaries.