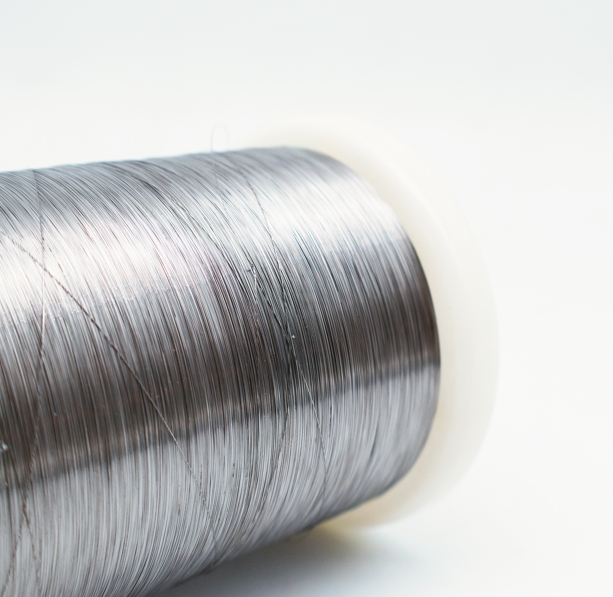

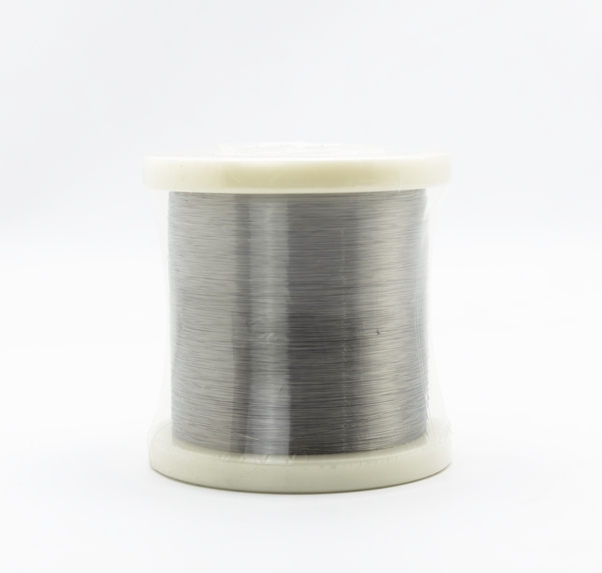

High purity Ni99.6 nickel wire plays a critical role in electronics assembly, lead wire production, and contract manufacturing. At DLX, we produce and supply factory-direct Ni99.6 nickel wire designed for precision electrical and electronic applications where consistency is everything.

In electronics manufacturing, materials must behave predictably under welding, soldering, bending, and long-term electrical load. Pure nickel wire provides that predictability. With a minimum nickel content of 99.6%, Ni99.6 ensures stable conductivity and uniform mechanical properties across production batches.

From our perspective at DLX, supplying nickel wire for electronics is not just about meeting a chemical composition requirement. It is about supporting high-speed automated production lines with materials that reduce defects and improve yield rates.

For more details, pls directly contact us.

Electronics assembly requires materials that combine conductivity, corrosion resistance, and ease of processing. Ni99.6 nickel wire meets these requirements through its simple and stable chemical composition.

The material offers consistent electrical resistance, which is critical for lead wires and connectors. Variations in conductivity can impact device performance, especially in precision electronic components.

Ni99.6 also demonstrates excellent weldability. In resistance welding and spot welding processes commonly used in electronics assembly, pure nickel forms strong and reliable joints with minimal spatter or instability.

Another advantage is ductility. The wire can be bent and shaped without cracking, which supports complex component design and automated forming operations.

High Purity Ni99.6 Nickel Wire – Technical Parameters

| Parameter | Ni99.6 Nickel Wire |

|---|---|

| Nickel Content | ≥ 99.6% |

| Equivalent Grade | Nickel 200 / UNS N02200 |

| Standard | ASTM B160 / DIN 2.4060 / JIS NW2200 |

| Density | 8.89 g/cm³ |

| Electrical Resistivity | ~0.096 μΩ·m |

| Melting Point | ~1455°C |

| Condition | Annealed / Hard Drawn |

| Corrosion Resistance | Excellent in alkali & neutral media |

| Typical Use | Electronics, lead wire, connectors |

Ni99.6 nickel wire is widely used in lead wires, battery connectors, relay components, sensor elements, and electronic terminal pins. In these applications, dimensional precision and surface cleanliness are crucial.

Lead wires must carry current reliably over long periods. Pure nickel ensures stable conductivity while resisting corrosion in humid or chemically active environments.

In battery-related electronics, nickel wire is used for tabs and internal connectors due to its compatibility with welding processes and low contact resistance.

Contract manufacturers often integrate Ni99.6 wire into customized assemblies for industrial, automotive, and energy-related devices. The material’s versatility simplifies procurement and standardization across multiple product lines.

Industry Trends Supporting Demand

The global expansion of electronics manufacturing, energy storage systems, and smart devices is driving continuous demand for high purity nickel materials.

Miniaturization of electronic components increases the need for fine and ultra-fine nickel wire with tight tolerances. At the same time, automation requires materials with consistent mechanical properties to avoid production interruptions.

Another major trend is supply chain stability. Electronics manufacturers prefer long-term cooperation with reliable material producers to reduce qualification cycles and ensure consistent quality.

Sustainability is also influencing material selection. Nickel is recyclable and offers long service life, aligning with modern environmental and efficiency standards.

DLX aligns with these industry trends by focusing on controlled production, batch traceability, and responsive communication.

DLX Compared with Typical Market Suppliers

In the market, high purity nickel wire is sometimes sourced through distributors who may change suppliers based on pricing fluctuations. This can lead to inconsistent surface quality, variation in tensile strength, and unstable delivery schedules.

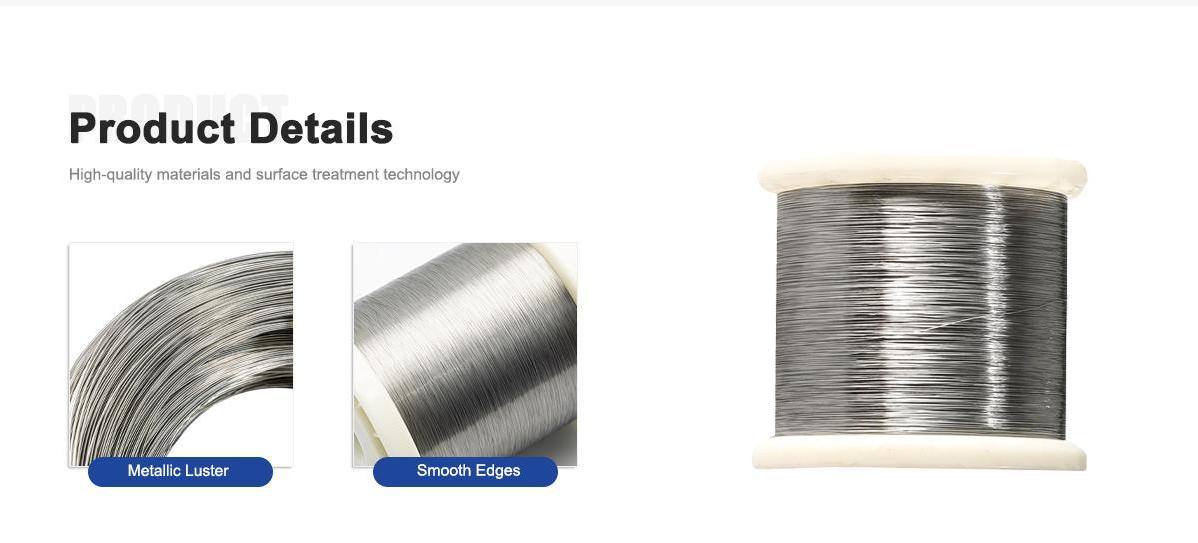

At DLX, Ni99.6 nickel wire is manufactured under controlled internal processes. Chemical composition is verified for each batch, and dimensional tolerances are carefully monitored during drawing and finishing.

We also understand the real needs of electronics assembly lines. Instead of offering generic data sheets, we work with customers to confirm diameter tolerance, surface finish, and temper condition based on their production process.

This practical approach helps reduce defects and improve assembly efficiency.

DLX Advantages for Contract Manufacturing

Contract manufacturers operate under tight production schedules and strict quality standards. Material inconsistency can result in high scrap rates or delayed shipments.

DLX provides factory-direct Ni99.6 nickel wire with stable supply planning and flexible MOQ. Whether customers need prototype quantities or large-volume supply, we support consistent delivery.

We also offer customized spooling and packaging solutions that integrate smoothly into automated feeding systems. This reduces handling time and improves workflow efficiency.

Full material certification and inspection documentation are available to support quality audits and customer requirements.

Long-Term Value of High Purity Nickel Wire Supply

In electronics and contract manufacturing, long-term reliability is essential. Materials must perform consistently not only during assembly but throughout the product lifecycle.

Ni99.6 nickel wire offers a proven combination of conductivity, corrosion resistance, and mechanical stability. When supplied with strict quality control and reliable logistics, it becomes a dependable foundation for electronic component production.

At DLX, we focus on long-term partnerships. By delivering consistent high purity nickel wire and responsive support, we help electronics manufacturers maintain stable production, reduce waste, and improve competitiveness in global markets.

High purity Ni99.6 nickel wire is not just a raw material. It is a performance-critical component in modern electronics manufacturing. With factory-direct control and industry understanding, DLX ensures that this material delivers real value to electronics assembly and contract manufacturing customers worldwide.

For more details, pls directly contact us.

About Us:

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications.

For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

1. What is Ni99.6 nickel wire?

Ni99.6 nickel wire refers to commercially pure nickel wire with a minimum nickel content of 99.6%. It offers stable electrical conductivity, excellent corrosion resistance, and good mechanical workability, making it suitable for electronics and precision assemblies.

2. Is Ni99.6 the same as Nickel 200?

Yes, Ni99.6 generally corresponds to Nickel 200 (UNS N02200) under ASTM B160. It may also align with DIN 2.4060 and JIS NW2200 depending on the standard applied.

3. Why is high purity important in electronics assembly?

High purity ensures stable conductivity, low contamination risk, consistent welding behavior, and reliable long-term performance in sensitive electronic components.

4. What are the main applications of Ni99.6 nickel wire?

Applications include lead wires, connectors, battery tabs, sensor components, micro-electronic assemblies, heating elements, and contract manufacturing parts.

5. Is Ni99.6 nickel wire easy to weld and solder?

Yes. Pure nickel wire offers excellent weldability and solderability, making it ideal for automated spot welding, resistance welding, and precision assembly processes.

6. What sizes can DLX supply?

DLX provides fine wire, ultra-fine wire, standard round wire, and customized diameters. Surface condition and packaging can be tailored for electronics production lines.

7. How does Ni99.6 perform in corrosive environments?

Ni99.6 offers strong resistance to alkalis, neutral salts, and mild acids, making it suitable for electronic devices exposed to humidity or chemical environments.

8. Why do contract manufacturers choose pure nickel wire?

Contract manufacturers value consistent quality, predictable mechanical behavior, and stable supply, all of which are critical for maintaining high production yields.