Soft annealed pure nickel wire is manufactured from high-purity nickel with a minimum nickel content of 99.6%. The most commonly used international grades include:

-

Nickel 200 – UNS N02200 – DIN 2.4060

-

Nickel 201 – UNS N02201 – DIN 2.4066

-

ASTM B160 / ASTM B162

Nickel 200 is suitable for most industrial and electrical applications, while Nickel 201 contains lower carbon content (≤0.02%), making it more stable in high-temperature environments and reducing the risk of graphite precipitation.

Soft annealing is a critical process. Through controlled heat treatment, the nickel wire achieves:

-

Improved ductility

-

Lower hardness

-

Enhanced weldability

-

Stable electrical conductivity

-

Better feeding performance in automatic equipment

This makes soft annealed pure nickel wire especially suitable for electrical connectors, battery tabs, welding wire, lead wires, and industrial procurement projects requiring large-volume consistency.

For more details, pls directly contact us.

| Property | Nickel 200 (N02200) | Nickel 201 (N02201) |

|---|---|---|

| Nickel Content | ≥ 99.6% | ≥ 99.6% |

| Carbon | ≤ 0.15% | ≤ 0.02% |

| Density | 8.89 g/cm³ | 8.89 g/cm³ |

| Melting Point | 1435–1446°C | 1435–1446°C |

| Tensile Strength (Soft) | 380–480 MPa | 380–480 MPa |

| Elongation | ≥ 35% | ≥ 35% |

| Electrical Resistivity | ~0.096 μΩ·m | ~0.096 μΩ·m |

| Hardness (Annealed) | ≤ 110 HV | ≤ 100 HV |

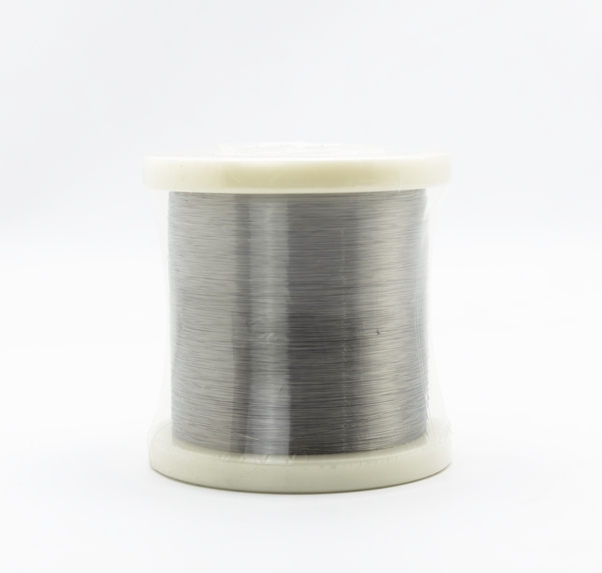

Available diameters typically range from 0.02 mm to 12 mm, supplied in coil, spool, or straightened cut lengths according to procurement requirements.

Main Applications

-

Electrical Conductivity Components

Used in connectors, terminals, lead wires, and precision electronic assemblies where stable conductivity is required. -

Spot Welding and Resistance Welding

Soft annealed nickel wire provides excellent welding performance with minimal spatter and consistent joint strength. -

Lithium Battery Pack Manufacturing

Widely used for battery tabs and interconnections due to its flexibility and conductivity. -

Industrial Heating and Sensor Leads

Suitable for controlled current applications in industrial equipment. -

Hydrogen and Electrochemical Systems

Resistant to alkaline corrosion, making it suitable for electrolysis and fuel cell systems. -

Chemical Processing Environments

Maintains stability in caustic alkali exposure.

Industry Trends

The global shift toward electrification and renewable energy continues to drive demand for conductive and corrosion-resistant materials. Several trends are shaping the soft annealed nickel wire market:

-

Expansion of lithium battery manufacturing capacity

-

Rapid growth of hydrogen production infrastructure

-

Increased automation in welding and assembly lines

-

Higher requirements for material traceability and batch consistency

-

Procurement strategies focused on long-term supply reliability

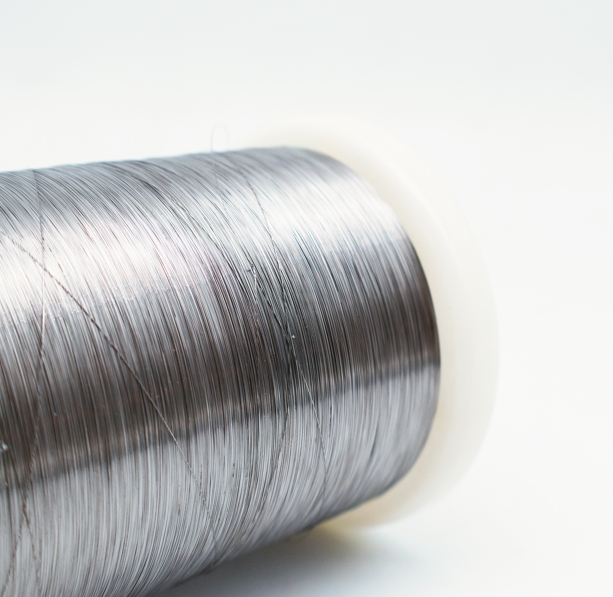

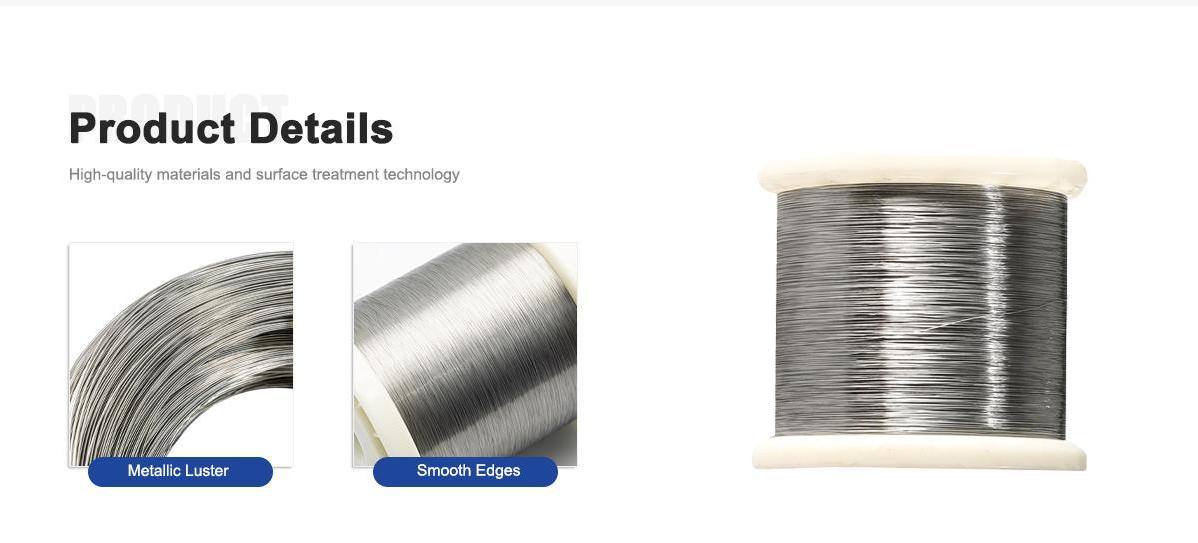

Industrial buyers are no longer focused solely on price. They are looking for stable mechanical properties, smooth surface finish, consistent electrical performance, and dependable supply chains.

Soft annealed nickel wire plays a critical role in automated production lines where feeding stability and repeatable welding results are essential.

Soft annealed pure nickel wire might look like a simple industrial material, but in modern manufacturing, it plays a strategic role. Electrical conductivity, welding reliability, and mechanical flexibility must work together — especially in high-volume industrial procurement.

At DLX Company, we approach soft annealed nickel wire not as a commodity, but as a precision-engineered solution.

Pure nickel, with a minimum content of 99.6%, offers a rare combination of conductivity and corrosion resistance. When properly annealed, it becomes highly ductile, easy to process, and ideal for automated production systems.

Electrical performance is the foundation. In connectors, battery tabs, and lead wires, stable resistivity ensures efficient current transmission. Any inconsistency in composition or microstructure can impact performance. That is why strict melting control and impurity management are critical.

Welding performance is another key factor. In resistance welding applications, hardness and surface condition directly affect weld strength. Overly hard material can cause unstable contact and inconsistent fusion. Soft annealed nickel wire eliminates that risk by providing uniform mechanical behavior and clean surface conditions.

The battery industry is a clear example. As production volumes increase, manufacturers rely heavily on automated welding machines. Feeding stability and consistent mechanical properties determine production efficiency. A slight deviation in tensile strength can disrupt thousands of units per hour. That’s why batch consistency is more important than ever.

Hydrogen and electrochemical systems represent another growing sector. Alkaline electrolysis environments are highly corrosive. Materials must resist degradation over long operating cycles. Pure nickel performs exceptionally well in these conditions, maintaining both structural integrity and conductivity.

From an industry perspective, the demand for high-purity nickel wire is growing steadily. Electrification trends, renewable energy investments, and infrastructure upgrades are driving procurement at larger scales. Buyers now evaluate suppliers based on:

-

Production capacity

-

Quality stability

-

Technical support

-

Delivery reliability

-

Long-term cooperation potential

At DLX, we understand these expectations.

Our production process begins with carefully selected raw materials to ensure purity. Melting and refining are strictly controlled to minimize impurities. Drawing operations maintain tight dimensional tolerances. Most importantly, annealing parameters are precisely managed to achieve consistent softness and elongation.

Consistency is our strength. Many industrial buyers face issues such as fluctuating tensile strength between batches or unstable welding results. We focus heavily on process repeatability to ensure that each shipment matches the previous one.

Surface quality is another key advantage. Clean, oxide-controlled surfaces improve welding performance and reduce post-processing requirements. This translates directly into higher production efficiency for our customers.

Customization is also essential. Different industries require different mechanical properties. Some customers need extra flexibility for complex forming. Others require slightly higher strength for structural stability. Through controlled annealing cycles, we tailor mechanical performance according to application needs.

Procurement teams are also increasingly focused on supply chain reliability. Production delays can cause costly downtime. Our integrated manufacturing and inventory management allow us to provide stable lead times and flexible order quantities.

Compared to standard market supply, DLX offers a more controlled and engineering-driven approach. We do not compete only on price. We compete on stability, technical precision, and long-term partnership value.

For B2B buyers, the total cost of ownership matters more than initial price. Stable material performance reduces rejection rates, improves welding yield, and enhances product durability. Over time, that creates significant cost savings.

Soft annealed pure nickel wire is essential in industries such as:

-

Lithium battery manufacturing

-

Electrical connector production

-

Resistance welding systems

-

Hydrogen electrolysis equipment

-

Industrial automation components

We position ourselves as a strategic manufacturing partner for these sectors.

Looking forward, the global push for clean energy and industrial automation will continue to increase demand for conductive and corrosion-resistant materials. Suppliers must evolve from simple material providers to technical solution partners.

At DLX, we are ready for that evolution.

Our soft annealed pure nickel wire delivers conductivity, flexibility, and reliability — not just in laboratory testing, but in real production environments. With strict quality control, customizable mechanical properties, and dependable supply capability, we support industrial procurement teams seeking long-term stability.

Precision, consistency, and trust define our approach. In a market where performance tolerances are tightening and expectations are rising, those qualities make the difference.

For more details, pls directly contact us.

About Us:

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications.

For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

-

What does “soft annealed” mean?

Soft annealed refers to heat-treated nickel wire that has reduced hardness and improved ductility, making it easier to form and weld. -

Why is soft annealed nickel better for welding?

Lower hardness improves contact performance during spot welding, resulting in stronger and more consistent weld joints. -

What is the difference between Nickel 200 and Nickel 201?

Nickel 201 has lower carbon content, which improves stability in high-temperature applications. -

Is soft annealed nickel wire suitable for automatic feeding systems?

Yes. Its flexibility and uniform diameter ensure smooth feeding in automated equipment. -

Can mechanical properties be customized?

Yes. Tensile strength and elongation can be adjusted through controlled annealing processes. -

How does nickel perform in alkaline environments?

Pure nickel shows excellent resistance to caustic alkalis, making it suitable for electrochemical systems. -

What surface finishes are available?

Bright, clean surface finish with strict control over oxide layers to ensure welding performance. -

What documentation can be provided?

Mill test certificates, chemical composition reports, and third-party inspection documents are available upon request.