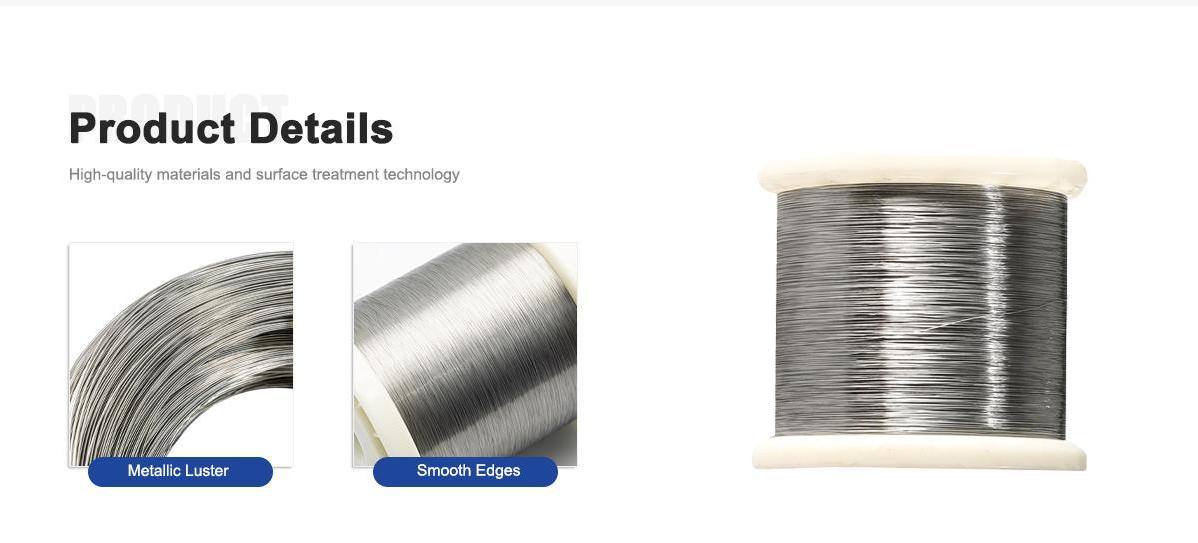

Nickel 201 wire JIS NW2200 / NW2201 is a critical material in modern furnace manufacturing and high-temperature engineering. At DLX, we supply high purity Nickel 201 wire to furnace manufacturers and engineering companies that require stability, consistency, and long service life in demanding thermal environments.

High-temperature systems are unforgiving. Materials must withstand continuous heat cycles, oxidation exposure, and mechanical stress without losing structural integrity. Nickel 201 wire is specifically engineered to meet these challenges through its ultra-low carbon composition and high nickel purity.

From our experience working with furnace manufacturers, reliability is the priority. A small material inconsistency can lead to equipment downtime or expensive maintenance. That is why DLX focuses on tight quality control and stable production standards.

For more details, pls directly contact us.

The key advantage of Nickel 201 wire lies in its low carbon content. When pure nickel materials operate above 600°C, higher carbon levels can lead to graphite formation, reducing ductility and structural stability. Nickel 201 minimizes this risk, making it ideal for sustained high-temperature exposure.

Nickel 201 also demonstrates strong oxidation resistance. In furnace atmospheres, especially those containing controlled oxygen levels, the material forms a stable oxide layer that protects the underlying metal.

Mechanically, Nickel 201 maintains good ductility and formability even after prolonged thermal cycles. This allows furnace manufacturers to design heating elements, support wires, and internal components that retain their shape and performance over time.

| Grades | N4/Ni201 | N6/Ni200 |

| Density | 8.9g/cm³ | 8.9g/cm³ |

| Melting Point | 1455°C | 1445-1470℃ |

| Coefficient of Thermal Expansion | 13.0µm/m·°C | 13.3×10⁻⁶/℃ |

| Thermal Conductivity | 10.1W/m·K | 90.7 W/m·K |

| Electrical Resistivity | 0.103×10⁻⁶Ω·/m (at 20℃) | |

| Electrical Conductivity | 14.6% IACS | |

| Tensile Strength | ≥450MPa | ≥450 MPa |

| Yield Strength | ≥200MPa | ≥150 MPa |

| Elongation at Break | ≥40% | ≥40% |

| Hardness | ≤150 |

For more details, pls directly contact us.

Furnace manufacturers use Nickel 201 wire in resistance heating elements, internal structural supports, thermocouple protection components, and high-temperature electrical connectors.

In heat treatment furnaces, stable electrical resistance is essential. Nickel 201 wire provides predictable resistance values, which helps ensure uniform heat distribution inside the chamber.

In vacuum furnaces and controlled atmosphere systems, Nickel 201 performs reliably due to its chemical stability and low impurity content. This reduces contamination risk and supports precision thermal processes.

Nickel 201 Wire JIS NW2200 / NW2201 – Technical Comparison Table

| Parameter | Nickel 201 (NW2201) | Nickel 200 (NW2200) |

|---|---|---|

| Nickel Content | ≥ 99.6% | ≥ 99.6% |

| Carbon Content | ≤ 0.02% | ≤ 0.15% |

| Standard | JIS NW2201 / ASTM B160 | JIS NW2200 / ASTM B160 |

| Equivalent DIN | 2.4066 | 2.4060 |

| Density | 8.89 g/cm³ | 8.89 g/cm³ |

| Electrical Resistivity | ~0.096 μΩ·m | ~0.096 μΩ·m |

| Recommended Service Temp | Up to ~800°C | Up to ~600°C |

| Oxidation Resistance | Excellent | Very Good |

| Typical Applications | Furnaces, high-temp engineering | General industrial use |

Beyond traditional furnace applications, Nickel 201 wire is increasingly used in advanced high-temperature engineering projects. These include energy conversion systems, hydrogen-related equipment, and specialized thermal processing units.

As industries push toward higher efficiency and higher operating temperatures, materials must keep up. Nickel 201 wire offers a balance between performance and cost-effectiveness, making it a practical solution for many engineering designs.

Energy equipment manufacturers value Nickel 201 because it combines corrosion resistance with temperature stability, reducing the need for frequent component replacement.

Industry Trends Driving Demand

The global expansion of industrial heat treatment, advanced manufacturing, and energy infrastructure is driving consistent demand for high-purity nickel materials.

Furnace technology is evolving toward higher precision and longer continuous operation cycles. This increases the need for materials that resist thermal fatigue and carbon-related degradation.

Additionally, many engineering companies are consolidating their supplier base, preferring manufacturers that can provide standardized materials across multiple international standards. Nickel 201 wire meeting JIS, ASTM, and DIN standards simplifies global sourcing.

At DLX, we see increasing interest from furnace manufacturers who prioritize long-term reliability and stable supply over short-term cost savings.

DLX Compared with Typical Suppliers

In the marketplace, Nickel 201 wire is sometimes sourced through trading channels, which can result in inconsistent quality and variable delivery performance.

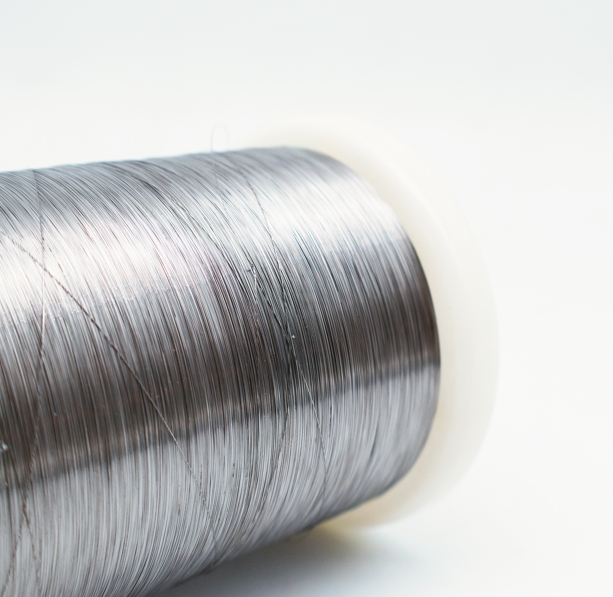

DLX operates as a manufacturer with controlled production processes. Chemical composition is verified through internal testing, and wire diameter tolerance is closely monitored to meet engineering requirements.

We also understand furnace manufacturing realities. Instead of offering generic product data, we discuss application temperature ranges, thermal cycling conditions, and mechanical stress factors with customers before confirming specifications.

This practical approach reduces material mismatch and improves overall project performance.

DLX Advantages for Furnace Manufacturers

DLX provides factory-direct Nickel 201 wire with stable batch control and full material certification. For furnace manufacturers, this means predictable integration into heating systems and reduced risk of unexpected material failure.

We offer flexible MOQ for prototype development as well as bulk supply for mass production. Customized spool sizes and packaging support workshop efficiency and export logistics.

Our team responds quickly to technical inquiries, helping engineering customers adjust specifications when project requirements evolve.

Long-Term Partnership in High-Temperature Engineering

Furnace and high-temperature engineering projects require more than just material supply. They require consistent cooperation.

At DLX, we focus on building long-term relationships with furnace manufacturers and engineering companies. By providing reliable Nickel 201 wire and maintaining stable quality across batches, we help customers standardize production and reduce operational risk.

Nickel 201 wire JIS NW2200 / NW2201 remains a trusted material for high-temperature applications. When supplied with strict quality control and real application understanding, it delivers

For more details, pls directly contact us.

About Us:

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications.

For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

1. What is Nickel 201 wire?

Nickel 201 wire is a commercially pure nickel material with a minimum nickel content of 99.6% and ultra-low carbon content. It is specifically designed for high-temperature applications where carbon embrittlement must be avoided.

2. What do JIS NW2200 and NW2201 mean?

JIS NW2200 and NW2201 are Japanese Industrial Standard designations for pure nickel grades equivalent to Ni200 and Ni201. NW2201 corresponds to low-carbon Nickel 201, which is preferred for high-temperature furnace environments.

3. Why is Nickel 201 suitable for furnace manufacturing?

Nickel 201 offers excellent resistance to oxidation, good structural stability at elevated temperatures, and strong resistance to alkaline and neutral chemical environments. Its low carbon content improves long-term performance above 600°C.

4. What is the difference between Nickel 200 and Nickel 201?

The main difference is carbon content. Nickel 201 has significantly lower carbon, reducing the risk of graphite precipitation in high-temperature conditions. This makes Nickel 201 more reliable for continuous furnace operation.

5. Which standards are equivalent to JIS NW2201?

JIS NW2201 is equivalent to UNS N02201, ASTM B160 Nickel 201, and DIN 2.4066, making it compatible with global high-temperature engineering projects.

6. What industries use Nickel 201 wire?

Nickel 201 wire is widely used in furnace manufacturing, heat treatment equipment, thermal processing systems, energy engineering, chemical processing, and high-temperature electrical components.

7. Can DLX supply customized specifications?

Yes. DLX provides customized diameters, temper conditions (annealed or hard-drawn), coil sizes, and packaging to match furnace and engineering production requirements.

8. Is Nickel 201 suitable for long-term high-temperature service?

Yes. Nickel 201 maintains mechanical integrity and chemical stability during extended exposure to high temperatures, making it ideal for continuous furnace operation.