Pure nickel wire is primarily produced from high-purity nickel, typically Ni ≥ 99.6%. The most common international grades include:

-

UNS N02200 ( Nickel 200 )

-

UNS N02201 ( Nickel 201 – low carbon version)

-

DIN 2.4060 / 2.4066

-

ASTM B160 / B162

Nickel 200 is widely used for general industrial applications, while Nickel 201 is preferred in high-temperature environments where lower carbon content prevents graphite precipitation.

Pure nickel wire offers:

-

Excellent electrical conductivity

-

Strong corrosion resistance in alkaline environments

-

High ductility and formability

-

Stable performance under high current load

-

Good weldability and solderability

These properties make it highly suitable for battery tabs, fuel cell connectors, hydrogen electrolysis electrodes, and precision electronic components.

For more details, pls directly contact us.

Typical Technical Parameters

| Property | Nickel 200 (N02200) | Nickel 201 (N02201) |

|---|---|---|

| Nickel Content | ≥ 99.6% | ≥ 99.6% |

| Carbon | ≤ 0.15% | ≤ 0.02% |

| Density | 8.89 g/cm³ | 8.89 g/cm³ |

| Melting Point | 1435–1446°C | 1435–1446°C |

| Tensile Strength | 380–550 MPa | 380–550 MPa |

| Elongation | ≥ 30% | ≥ 30% |

| Electrical Resistivity | ~0.096 μΩ·m | ~0.096 μΩ·m |

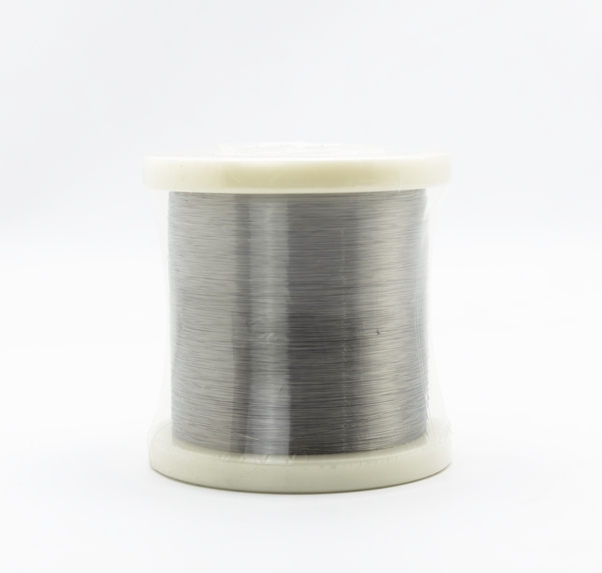

Available forms:

-

Soft annealed wire

-

Bright surface wire

-

Straightened and cut wire

-

Precision micro wire (0.02 mm and above)

Main Applications

-

Lithium Battery Tabs and Connectors

Pure nickel wire is widely used in cylindrical and pouch lithium battery packs for tab welding due to its conductivity and corrosion resistance. -

Fuel Cell Systems

Nickel wire functions as a conductive and corrosion-resistant component in PEM and alkaline fuel cells. -

Hydrogen Electrolysis Equipment

Used in alkaline electrolysis systems where nickel provides long-term stability in strong alkaline media. -

Electronic Assembly and Lead Wires

Suitable for precision electronics, sensor leads, and terminal connections. -

Spot Welding Materials

Ideal for battery pack welding and contract manufacturing applications. -

Chemical Processing Equipment

Resistant to caustic alkali environments.

Industry Trends

The demand for pure nickel wire is closely linked to three fast-growing sectors:

-

New Energy Vehicles (EVs)

Battery manufacturing capacity continues to expand globally, increasing demand for high-purity nickel tab materials. -

Hydrogen Economy

Hydrogen electrolysis and fuel cell projects are scaling rapidly, driving demand for corrosion-resistant conductive materials. -

Energy Storage Systems

Grid storage and renewable integration require reliable battery connections and conductive components.

Buyers now focus more on:

-

Material traceability

-

Stable resistivity control

-

Consistent mechanical properties

-

High welding performance

-

Supply chain reliability

Quality consistency is becoming more important than just price.

Pure nickel wire is no longer just a traditional industrial material. Today, it sits at the center of the energy transition. From lithium battery packs to hydrogen electrolysis systems, demand is accelerating, and quality standards are rising fast.

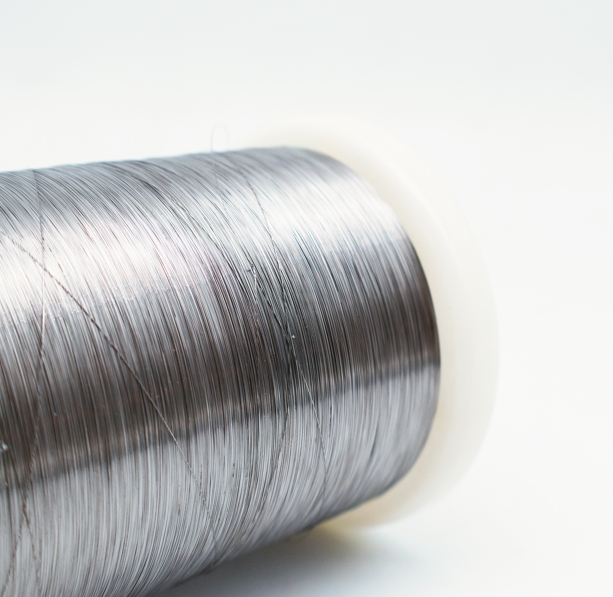

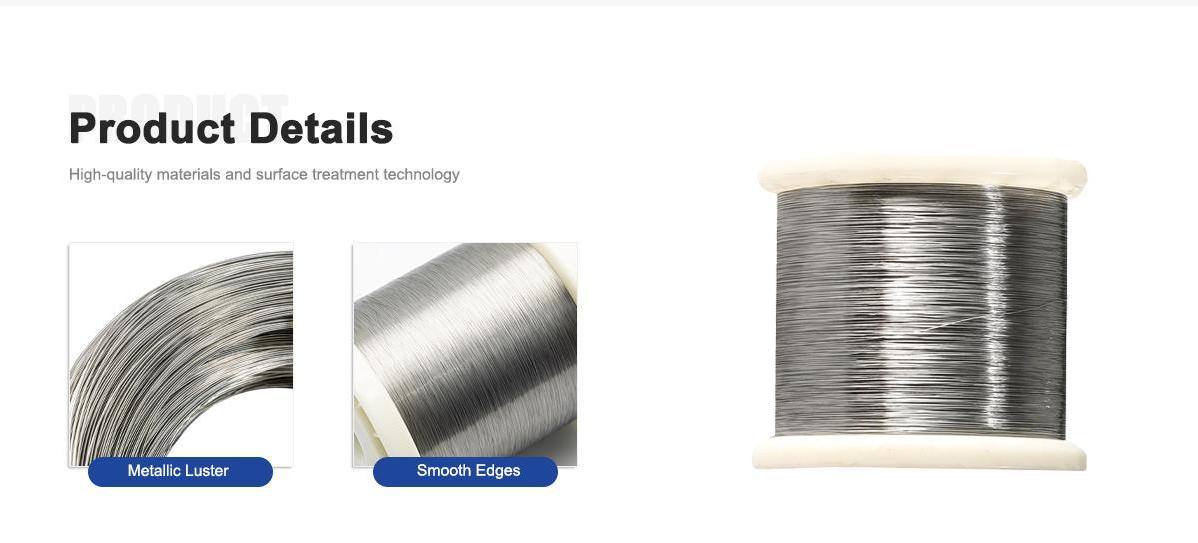

At DLX Company, we have seen this shift clearly. Buyers are no longer asking only for “nickel wire.” They ask for stable resistivity, controlled elongation, smooth surface finish, and consistent weldability. The market has become technical, precise, and quality-driven.

Pure nickel wire, especially Ni99.6 grade (Nickel 200 and 201), delivers a unique combination of conductivity and corrosion resistance. This balance makes it indispensable in energy storage and hydrogen systems. In lithium battery manufacturing, even slight fluctuations in resistivity can impact pack efficiency. That’s why stable chemistry and controlled annealing are critical.

In hydrogen electrolysis systems, materials must survive strong alkaline environments for thousands of operating hours. Nickel performs exceptionally well in these conditions, maintaining structural integrity and conductivity over long service cycles.

Fuel cells present another challenge. Conductive components must resist corrosion while maintaining mechanical flexibility. Pure nickel wire provides both. Its ductility allows precise forming, while its chemical stability ensures durability.

The industry trend is moving toward higher purity and tighter tolerances. Battery manufacturers demand uniform thickness and stable tensile strength to ensure automatic welding efficiency. Electrolysis equipment manufacturers require long-term corrosion data. Contract manufacturers need reliable supply and fast delivery.

This is where DLX stands apart.

We focus not only on chemical composition but also on process control. Our melting process ensures high purity raw material. Drawing and annealing are carefully managed to maintain consistent mechanical properties. Surface finish is strictly controlled to ensure clean welding performance.

Consistency is our core advantage. Many buyers face problems with unstable batches — one shipment welds perfectly, the next causes splashing or weak joints. We eliminate that variability through standardized production management and strict quality inspection.

Another advantage is customization capability. Different applications require different tensile strengths. Battery tabs may require softer material for easier welding, while structural connections may need higher strength. We adjust annealing conditions accordingly.

Supply reliability is also critical in today’s market. Energy projects operate on tight timelines. Delays in material supply can halt production lines. Our integrated production and inventory planning allow stable lead times and flexible batch sizes.

From a cost-performance perspective, pure nickel wire offers long-term value. While initial cost may be higher than plated alternatives, performance stability, corrosion resistance, and longer service life significantly reduce total lifecycle cost.

Looking ahead, the hydrogen economy and battery storage sectors will continue expanding. Governments worldwide are investing in renewable energy and decarbonization projects. This means increasing demand for reliable conductive materials.

At DLX, we position ourselves as a long-term partner rather than just a material supplier. We support technical discussions, provide material recommendations, and adapt specifications according to application needs.

Our pure nickel wire is engineered for:

-

Lithium battery manufacturers

-

Fuel cell system integrators

-

Hydrogen electrolysis equipment producers

-

Energy storage solution providers

-

Electronic assembly contractors

We understand that B2B customers value stability, traceability, and engineering support. That’s exactly what we deliver.

In an industry where performance tolerance is narrow and expectations are high, precision matters. Our experience in alloy production, strict inspection standards, and customer-focused manufacturing philosophy ensure that every coil of nickel wire meets industrial demands.

Pure nickel wire may look simple, but in advanced energy systems, it plays a critical role. Conductivity, corrosion resistance, and mechanical stability must work together. At DLX, we make sure they do.

For more details, pls directly contact us.

About Us:

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications.

For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

-

What is the difference between Nickel 200 and Nickel 201?

Nickel 201 has lower carbon content, making it more suitable for high-temperature applications to prevent embrittlement. -

Why is pure nickel used instead of nickel-plated steel for battery tabs?

Pure nickel offers better conductivity, corrosion resistance, and long-term reliability, especially in high-current applications. -

Can pure nickel wire be used in hydrogen electrolysis?

Yes. It performs very well in alkaline environments due to its corrosion resistance. -

What diameter range is available?

Typically from 0.02 mm to 10 mm, depending on application requirements. -

Is the wire suitable for automatic welding machines?

Yes. Soft annealed nickel wire ensures stable feeding and excellent weld consistency. -

How does nickel perform in alkaline solutions?

Pure nickel has outstanding resistance to caustic alkalis, making it ideal for electrochemical systems. -

Can customized tensile strength be provided?

Yes. Mechanical properties can be adjusted through controlled annealing processes. -

What certifications are typically available?

Mill test certificates, chemical analysis reports, and third-party inspection documents can be provided upon request.