Industrial grade pure nickel wire is typically manufactured with a minimum nickel content of 99.6%, ensuring high corrosion resistance, stable electrical conductivity, and reliable mechanical performance. The most recognized international standards include:

Nickel 200 – UNS N02200 – DIN 2.4060

Nickel 201 – UNS N02201 – DIN 2.4066

ASTM B160 / ASTM B162

Nickel 200 is widely used for general industrial environments, while Nickel 201 contains lower carbon content (≤0.02%), which makes it more suitable for elevated temperature applications, especially in heat treatment and furnace-related systems.

Key material characteristics:

Excellent resistance to caustic alkalis

Stable performance under high temperatures

Good thermal conductivity

High ductility and formability

Strong resistance to stress corrosion cracking in alkaline media

These properties make industrial grade pure nickel wire an ideal material for chemical processing equipment, heat treatment fixtures, OEM components, and export-oriented industrial supply chains.

For more details, pls directly contact us.

| Property | Nickel 200 (N02200) | Nickel 201 (N02201) |

|---|---|---|

| Nickel Content | ≥ 99.6% | ≥ 99.6% |

| Carbon | ≤ 0.15% | ≤ 0.02% |

| Density | 8.89 g/cm³ | 8.89 g/cm³ |

| Melting Point | 1435–1446°C | 1435–1446°C |

| Tensile Strength (Annealed) | 380–550 MPa | 380–550 MPa |

| Elongation | ≥ 30% | ≥ 30% |

| Thermal Conductivity | ~90 W/m·K | ~90 W/m·K |

| Electrical Resistivity | ~0.096 μΩ·m | ~0.096 μΩ·m |

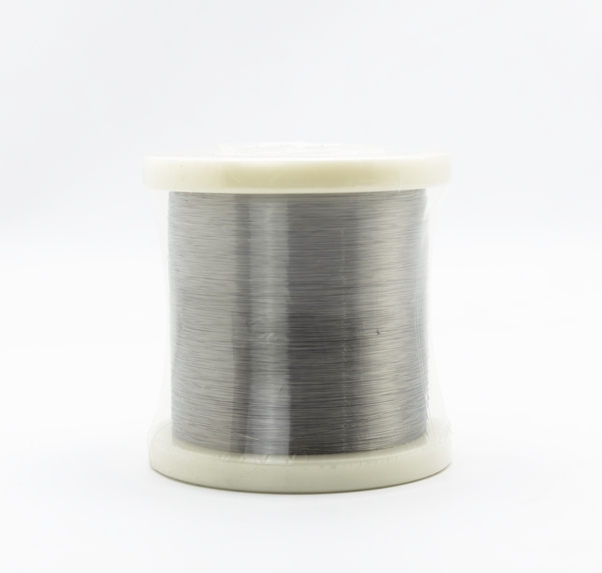

Available supply forms:

Soft annealed wire

Bright drawn wire

Straightened and cut lengths

Custom diameters from 0.02 mm to 15 mm

OEM packing for export projects

Main Applications

Chemical Processing Equipment

Used in alkali handling systems, heat exchangers, and reaction vessel components due to strong corrosion resistance.Heat Treatment Fixtures

Nickel wire performs reliably in controlled atmosphere furnaces and high-temperature assemblies.Industrial Furnace Components

Applied in supports, grids, and fixtures exposed to heat cycles.OEM Manufacturing

Widely used by equipment manufacturers requiring stable raw material for customized assemblies.Electrochemical Systems

Suitable for alkaline electrolysis and related systems.Industrial Fasteners and Connectors

Used where corrosion resistance and ductility are required.

Industry Trends

Industrial grade pure nickel wire demand is strongly influenced by several global trends:

Expansion of chemical processing capacity in emerging markets

Increasing investment in industrial heat treatment infrastructure

Growth of OEM manufacturing in Asia and the Middle East

Higher global standards for material traceability and export compliance

Supply chain diversification strategies

Chemical plants and heat treatment companies are placing greater emphasis on material lifespan and corrosion resistance to reduce downtime. At the same time, OEM buyers are focusing on stable mechanical performance and consistent quality across large export batches.

Price sensitivity still exists, but reliability and long-term cooperation have become key decision factors in industrial procurement.

For more details, pls directly contact us.

About Us:

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications.

For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

FAQ – Frequently Asked Questions

What is the difference between industrial grade and high-purity nickel wire?

Industrial grade nickel maintains ≥99.6% purity, optimized for durability and cost-performance balance in heavy-duty environments.Why is Nickel 201 preferred in heat treatment applications?

Its lower carbon content prevents embrittlement at elevated temperatures.Can nickel wire withstand strong alkaline chemicals?

Yes. Pure nickel offers excellent resistance to caustic alkalis.What temperature range can nickel wire tolerate?

It performs reliably up to approximately 600°C in many industrial applications, depending on conditions.Is customization available for OEM projects?

Yes. Diameter, tensile strength, surface finish, and packaging can be customized.How is export quality ensured?

Through strict chemical analysis, mechanical testing, and documentation such as mill test certificates.Can the wire be supplied in large industrial quantities?

Yes. Bulk coil supply and container-level export shipments are supported.What surface finish is recommended for chemical applications?

Bright and clean surface finishes are preferred to improve corrosion performance and processing consistency.

In-Depth Article

Industrial grade pure nickel wire plays a foundational role in chemical equipment, heat treatment systems, and OEM manufacturing supply chains. While it may not always be visible in finished equipment, its performance directly affects durability, safety, and operational efficiency.

At DLX Company, we view pure nickel wire as an engineered industrial solution rather than a simple commodity metal.

Pure nickel, especially Nickel 200 and Nickel 201 grades, offers a rare balance between corrosion resistance and mechanical workability. In chemical environments where caustic alkalis are present, many materials degrade quickly. Nickel maintains structural integrity, reducing maintenance cycles and extending equipment life.

Heat treatment applications create another set of challenges. High temperatures, repeated thermal cycles, and controlled atmospheres require materials that resist oxidation and embrittlement. Nickel 201, with its low carbon content, performs particularly well in such environments, preventing carbon-related cracking at elevated temperatures.

OEM manufacturers demand something slightly different. They require not only material performance but also supply stability. Production lines cannot stop because of inconsistent mechanical properties or delayed shipments. For export-oriented projects, documentation accuracy and packaging standards are equally important.

At DLX, we focus on all these aspects.

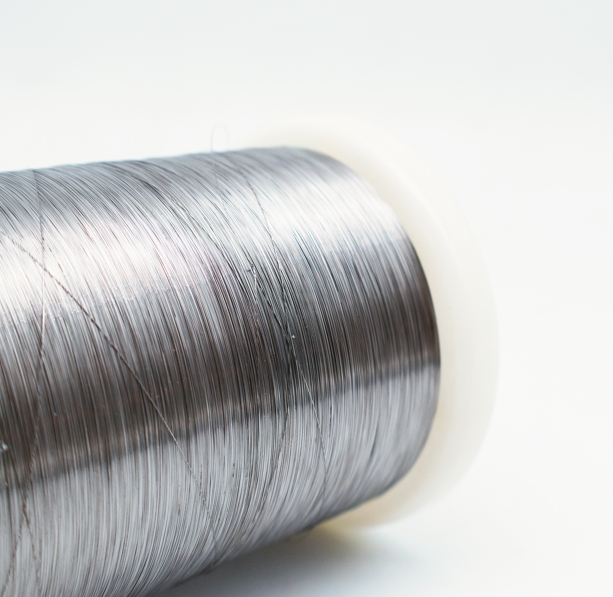

Material quality starts with raw nickel selection. We control melting processes carefully to maintain chemical stability. Drawing operations are managed with tight dimensional tolerance control to ensure consistent diameter across long production runs.

Annealing processes are precisely regulated to achieve uniform tensile strength and elongation. This is critical for industrial buyers who rely on predictable forming and assembly performance.

Surface quality also matters. In chemical equipment applications, surface defects can accelerate corrosion. We ensure clean, smooth finishes that improve durability and processing efficiency.

Compared to general market suppliers, DLX emphasizes process stability and batch consistency. Industrial customers often report challenges such as fluctuating hardness, surface oxidation, or dimensional deviation. We address these issues through systematic quality control procedures.

Another key advantage is export experience. Industrial procurement often involves large-volume orders shipped across regions. We understand container loading optimization, moisture protection packaging, and documentation compliance required for international trade.

In the chemical industry, downtime is expensive. A small material failure can cause major operational interruption. That is why many procurement teams prioritize reliability over minimal price differences. A stable supplier reduces risk across the entire project lifecycle.

Heat treatment facilities face similar concerns. Repeated thermal cycling places stress on metallic components. Material selection must consider long-term mechanical stability. Pure nickel provides dependable performance, particularly when carbon content is tightly controlled.

OEM supply chains require flexibility. Some projects demand specific tensile ranges. Others require customized coil sizes or straightened cut lengths. We adapt production schedules and technical parameters to match project requirements.

From a broader industry perspective, global industrial investment continues to grow, particularly in developing regions expanding chemical production and manufacturing capacity. At the same time, environmental regulations are becoming stricter. Durable, corrosion-resistant materials help reduce waste and extend equipment lifespan, aligning with sustainability goals.

DLX positions itself not simply as a wire exporter, but as a long-term industrial partner. We support technical discussions, recommend appropriate grades, and provide stable production planning for recurring orders.

Our industrial grade pure nickel wire supports:

Chemical processing plants

Heat treatment furnace manufacturers

Industrial equipment OEMs

Electrochemical system integrators

Engineering contractors

We understand that B2B buyers evaluate suppliers based on reliability, quality stability, and technical responsiveness. These values are integrated into our production philosophy.

Consistency is what differentiates strong suppliers from temporary ones. At DLX, every batch undergoes chemical verification and mechanical testing before shipment. Documentation transparency ensures confidence in every delivery.

In industrial procurement, trust is built over time. When materials perform reliably in demanding environments, partnerships strengthen. That is the foundation of our approach.

Industrial grade pure nickel wire may appear simple, but its role in chemical equipment and heat treatment systems is critical. Corrosion resistance, thermal stability, and mechanical consistency must align perfectly.

At DLX, we make sure they do.