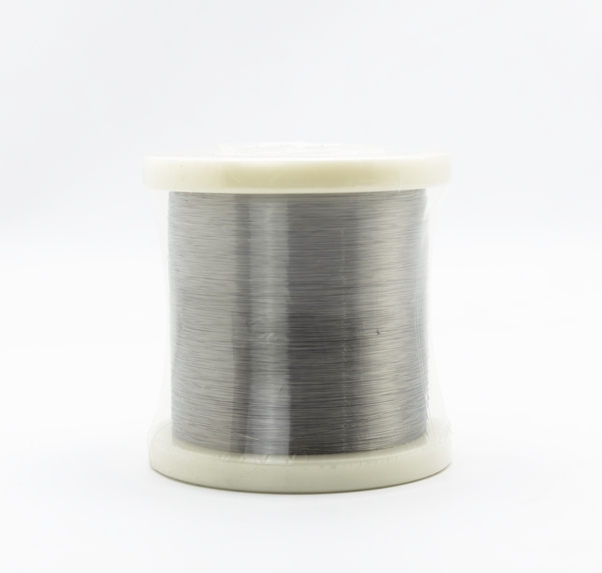

Nickel 200 wire 0.025 is a proven material for corrosion-resistant industrial projects where stability, reliability, and long service life are essential. At DLX, we manufacture and supply factory-direct Nickel 200 wire to bulk buyers and industrial customers who require consistent quality and dependable delivery.

From chemical plants to energy systems, Nickel 200 continues to be selected not because it is new, but because it is dependable. Its high purity and simple composition allow it to perform predictably in environments where complex alloys may introduce unnecessary risk.

At DLX, we focus on delivering Nickel 200 wire that performs consistently in real industrial conditions, not just in laboratory data sheets.

For more details, pls directly contact us.

The core advantage of Nickel 200 wire lies in its corrosion resistance. In alkaline solutions, caustic environments, and neutral salt conditions, Nickel 200 maintains structural integrity and surface stability over long periods.

The 0.025 wire size is especially versatile. It offers sufficient mechanical strength while remaining flexible enough for forming, winding, and precision assembly. This makes it suitable for heating elements, electrochemical equipment, and electrical conductors used in harsh environments.

Nickel 200 also offers stable electrical conductivity. While it is not designed to replace copper in high-conductivity applications, it performs reliably where corrosion resistance and electrical stability must coexist.

| Grades | N4/Ni201 | N6/Ni200 |

| Density | 8.9g/cm³ | 8.9g/cm³ |

| Melting Point | 1455°C | 1445-1470℃ |

| Coefficient of Thermal Expansion | 13.0µm/m·°C | 13.3×10⁻⁶/℃ |

| Thermal Conductivity | 10.1W/m·K | 90.7 W/m·K |

| Electrical Resistivity | 0.103×10⁻⁶Ω·/m (at 20℃) | |

| Electrical Conductivity | 14.6% IACS | |

| Tensile Strength | ≥450MPa | ≥450 MPa |

| Yield Strength | ≥200MPa | ≥150 MPa |

| Elongation at Break | ≥40% | ≥40% |

| Hardness | ≤150 |

For more details, pls directly contact us.

In chemical processing facilities, Nickel 200 wire is often used in heaters, support structures, sensors, and internal components exposed to corrosive chemicals. Its resistance to alkalis makes it particularly valuable in caustic soda and chemical transport systems.

In electroplating operations, Nickel 200 wire is widely used for anodes and current-carrying components. Its predictable dissolution behavior helps maintain bath stability and coating consistency.

Industrial heating is another key application. Nickel 200 wire is used in resistance heating elements operating in controlled atmospheres or corrosive environments where oxidation resistance is required.

For energy-related equipment, Nickel 200 wire is used in auxiliary components that must withstand chemical exposure while maintaining electrical performance.

Nickel 200 Wire 0.025 – Technical Parameter Comparison

| Parameter | Nickel 200 (UNS N02200) |

|---|---|

| Nickel Content | ≥ 99.6% |

| Carbon Content | ≤ 0.15% |

| Standard | ASTM B160 / DIN 2.4060 |

| Density | 8.89 g/cm³ |

| Electrical Resistivity | ~0.096 μΩ·m |

| Melting Point | ~1455°C |

| Recommended Service Temp | Up to ~600°C |

| Corrosion Resistance | Excellent in alkali & neutral media |

| Common Size | 0.025 wire |

Bulk buyers and project contractors value Nickel 200 wire for its consistency and availability. The material is standardized, widely accepted across industries, and supported by multiple international standards.

The 0.025 size simplifies inventory planning because it can be used across multiple applications with minimal modification. This versatility reduces the need for multiple material grades and sizes.

At DLX, we support bulk buyers with stable production scheduling, consistent batch quality, and packaging designed for industrial handling and long-distance transport.

Industry Trends Supporting Continued Demand

Despite rapid material innovation, demand for Nickel 200 wire remains strong. Chemical processing capacity expansion, energy infrastructure upgrades, and electrochemical equipment investments continue to drive steady consumption.

Another trend is risk reduction in supply chains. Many industrial customers prefer proven materials with predictable performance over newer alloys that may require long qualification cycles. Nickel 200 fits this preference perfectly.

Sustainability considerations also play a role. Nickel 200 is fully recyclable, and its long service life reduces replacement frequency, aligning with modern industrial sustainability goals.

DLX Compared with Typical Market Suppliers

In the market, Nickel 200 wire is often sold by trading companies that source material from multiple producers. This can result in inconsistent surface quality, variable mechanical properties, and uneven delivery schedules.

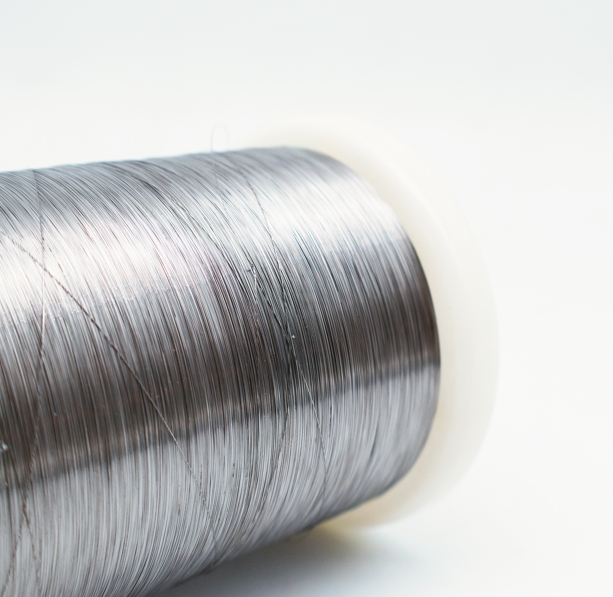

At DLX, Nickel 200 wire is produced under controlled manufacturing processes with strict quality inspection at every stage. Chemical composition, wire diameter, and surface condition are monitored batch by batch.

Our factory-direct model allows us to offer better traceability, faster response times, and more flexible customization compared with typical market suppliers.

DLX Advantages for Industrial Projects and Wholesalers

DLX works closely with industrial project managers and bulk buyers to ensure material suitability before shipment. We provide technical guidance on wire condition, size tolerance, and packaging based on actual application needs.

Flexible MOQ, stable pricing, and long-term supply planning help customers reduce procurement risk. Export-ready packaging ensures that Nickel 200 wire arrives in good condition, even for large-volume international shipments.

Full material certification and inspection documentation are provided to support quality audits and project approvals.

Long-Term Value of Choosing DLX Nickel 200 Wire

Industrial projects demand materials that perform reliably over years, not just months. Nickel 200 wire 0.025 offers proven corrosion resistance, stable electrical behavior, and easy processability.

At DLX, we focus on long-term partnerships. By supplying consistent Nickel 200 wire and supporting customers with practical technical insight, we help reduce downtime, improve production efficiency, and lower total operating costs.

Nickel 200 may be a classic material, but when supplied with modern quality control and factory-direct support, it continues to deliver strong value for corrosion-resistant industrial projects worldwide.

For more details, pls directly contact us.

About Us:

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications.

For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

1. What is Nickel 200 wire?

Nickel 200 wire is a commercially pure nickel material with a minimum nickel content of 99.6%. It is known for excellent corrosion resistance, stable electrical conductivity, and good mechanical properties. The 0.025 size is widely used in industrial projects that require precise control, flexibility, and consistent performance.

2. What does 0.025 mean in Nickel 200 wire?

0.025 typically refers to the wire diameter, commonly expressed in inches or millimeters depending on customer preference. This size is popular for industrial components, electrochemical equipment, heating elements, and electrical assemblies where balance between strength and flexibility is required.

3. Why is Nickel 200 suitable for corrosion-resistant applications?

Nickel 200 performs exceptionally well in alkaline environments, neutral salts, and many organic chemicals. It resists oxidation and chemical attack better than many alloyed materials, making it ideal for corrosive industrial environments.

4. Which industries commonly use Nickel 200 wire 0.025?

Nickel 200 wire 0.025 is widely used in chemical processing, electroplating systems, industrial heating, energy equipment, battery-related components, and OEM electrical assemblies.

5. What standards does Nickel 200 wire comply with?

Nickel 200 wire typically complies with ASTM B160, UNS N02200, DIN 2.4060, JIS NW2200, and GB/T standards, allowing it to be used in international industrial projects.

6. Is Nickel 200 wire easy to process?

Yes. Nickel 200 wire offers excellent ductility, weldability, and formability. It can be bent, cut, welded, and shaped without cracking, making it suitable for automated and manual production processes.

7. Can DLX supply Nickel 200 wire in bulk?

DLX specializes in bulk and project-based supply. We provide Nickel 200 wire 0.025 with stable batch quality, flexible MOQ, and export-ready packaging for industrial buyers and wholesalers.

8. How does Nickel 200 compare with other corrosion-resistant materials?

Compared with many alloy materials, Nickel 200 offers a simpler chemical composition, better resistance in alkaline environments, and more predictable performance, especially for long-term industrial use.